HS2 designers are set to more than halve the amount of embedded carbon used in one of the high-speed rail project’s viaducts.

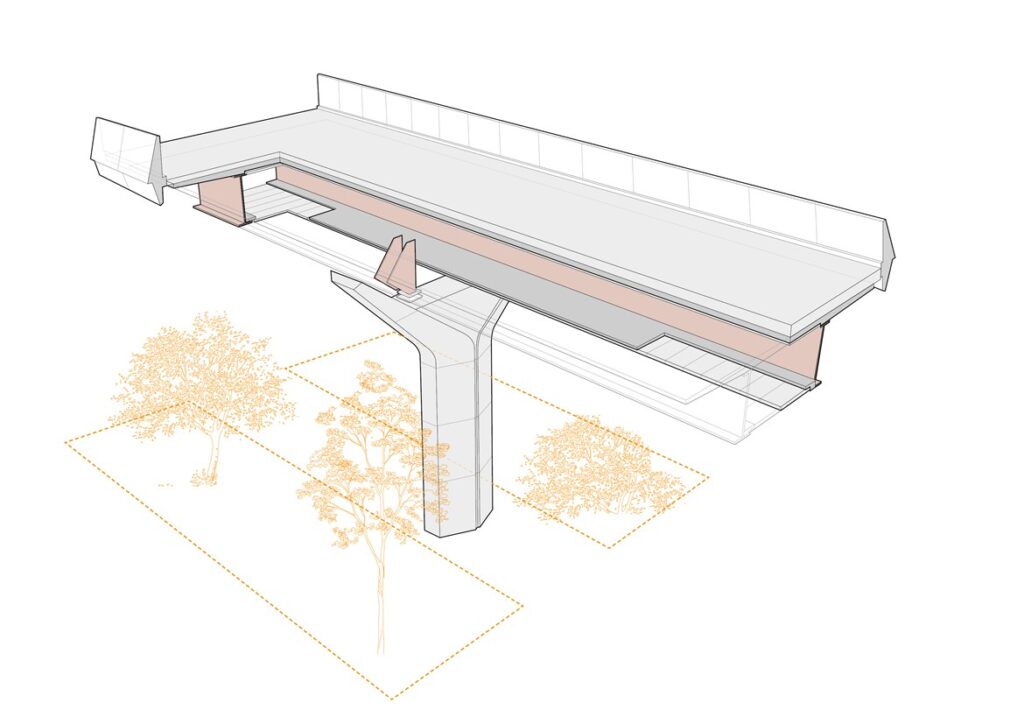

A double composite approach will be used on the Wendover Dean Viaduct in Buckinghamshire. This involves two steel girders sandwiched between two layers of reinforced concrete to create a super strong but lightweight span.

The 450m viaduct was recently given approval by Buckinghamshire Council under Schedule 17 of the HS2 Act and will be the first major railway viaduct in the UK to use this design approach.

it is one of 50 being built on the first phase of HS2 between London and the West Midlands, and has been designed by HS2’s main works contractor, EKFB – a team made up of Eiffage, Kier, Ferrovial and BAM Nuttall – working with design partner ASC (a joint venture between Arcadis Setec and COWI) and specialist architects Moxon.

Applying lessons from the use of double composite structures on the latest French TGV lines, the designers have cut the amount of embedded carbon in the viaduct by 7,433 tonnes – the equivalent of 20,500 return flights from London to Edinburgh.

In addition to reducing the amount of concrete and steel used in the structure – both significant sources of carbon dioxide – the slim design also decreases the structure’s silhouette when seen from across the valley. Nine equidistant piers will hold up the deck of the viaduct.

Ambrose McGuire, HS2 Ltd’s Project Client Director, said:We're serious about reducing the amount of carbon we use during construction and Wendover Dean is a great example of how we’re using the latest engineering techniques to do just that. Concrete is one of the construction industries’ biggest sources of embedded carbon – and this design will help us cut our carbon footprint while delivering a lighter, stronger and more elegant structure.

Another improvement on the original design is that the piers – some of which will measure up to 14m – will be cast in sections offsite and then be assembled in situ. This method will keep the amount of on-site work to a minimum, thereby keeping disruption for residents as low as possible.