Energy Absorbers – An Interview with Corex Honeycomb’s In-House Energy Mitigation Expert, Mehrdad Asadi, PhD

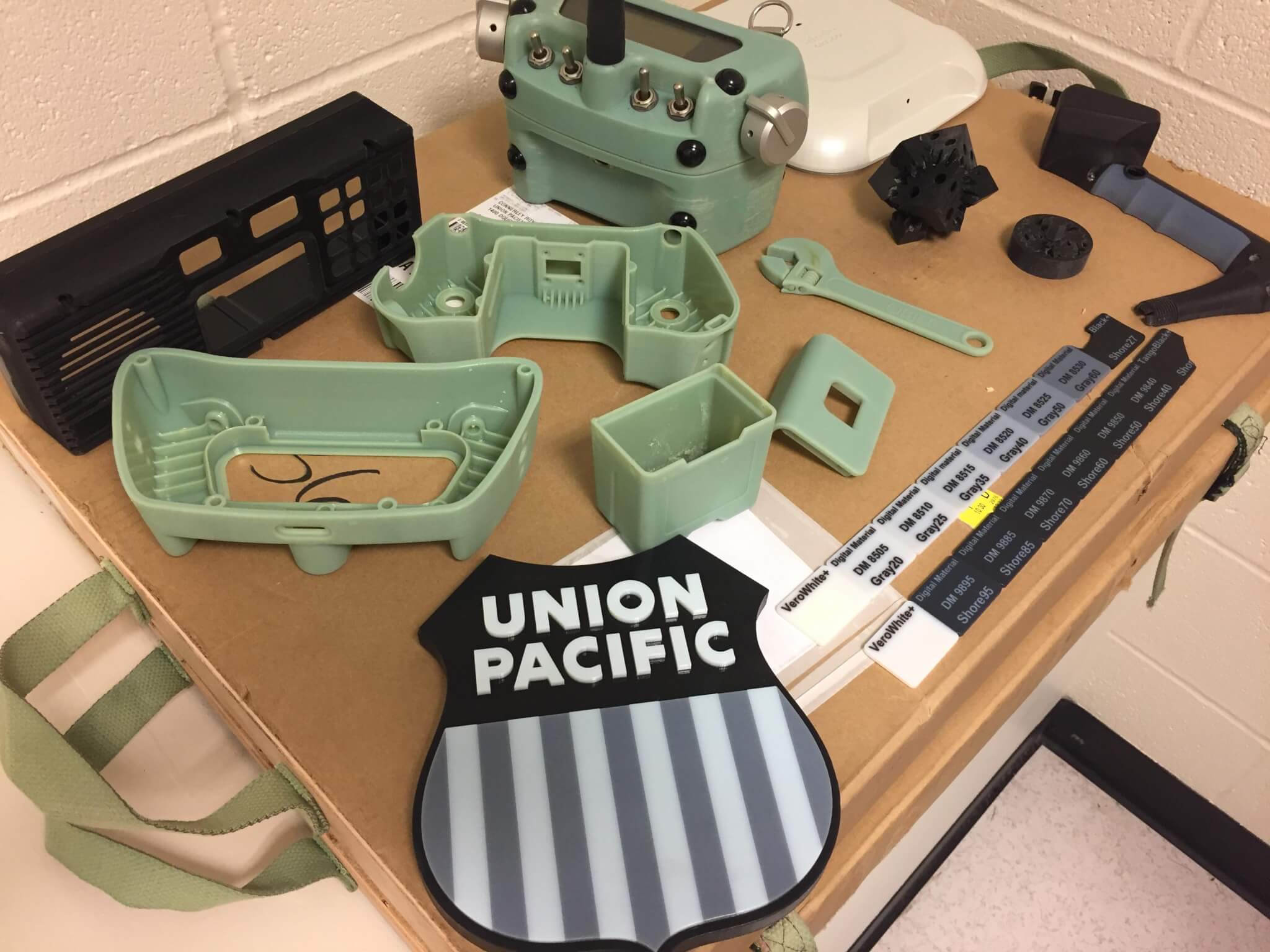

Corex Honeycomb has over 25 years of experience in the field of energy absorption and energy mitigation systems. Thanks to our specialist knowledge, we can engineer and manufacture standard and custom energy absorbers for a wide variety of applications by manufacturing different cell sizes, core densities and crush strengths to produce energy absorbers of all shapes and sizes. At Corex Honeycomb, we have expert engineers in our team. We interviewed one of our expert engineers, Mehrdad, who shared his knowledge of energy absorbers:

- What is your background and how did you become involved in energy absorbers?

While working at Corex Honeycomb I completed a Master’s degree in Structural Engineering, followed by a PhD in Mechanical Engineering, studying part-time. For my PhD, my dissertation was on FE (Finite Element) modelling of aluminium honeycomb and its application in crash test barrier models. During my time working for the company, I have been heavily involved in various projects using energy absorbers and impact dissipation systems, as well as analysing and testing those systems.

- What are the applications where energy mitigation systems are typically implemented?

There are a wide range of applications for energy mitigation systems; it is dependent on where and how they are implemented, as well as the sector they are used in. The main purpose of energy absorber systems is to mitigate unplanned or any expected kinetic energy, usually to prevent a structural failure or reduce the risk of death or serious injury when it involves human factors.

A common usage of energy absorbers is within crash test barriers, which are used in crash worthiness evaluations of new cars. In these barriers, aluminium honeycomb is used as the main energy absorber unit. Other examples of energy absorber usage include the car chassis design, where the energy absorbers are designed such to absorb a proportion of the impact energy caused during collisions. Aluminium honeycomb is also used in some of the attenuators we sell. Below are just some of the industries and ways energy mitigation systems can be utilised in:

- Commercial: Here at Corex Honeycomb, we can supply customer specific absorbers that provide impact protection for columns, racks and corners in warehouses and material handling facilities as well as many other applications.

- Motorsport: These products can help absorb the energy of an impact that occurs during a race and protect the vehicle and in doing so protect the occupants. They have also been successfully used to protect the fuel tank from unplanned impact during a race.

- Nuclear: When nuclear material is handled, Corex Honeycomb energy absorbers can be used as an insurance against unplanned incidents. It also has minimal impact on the shipping weight.

- Defence: Corex energy absorbers provide support and blast mitigation in doors, floors, seats and storage areas of military vehicles. Using energy absorbing floor panels in these vehicles can reduce the impact of land mine blasts and protect the personnel in the vehicle.

- Rail: Typical applications in the rail industry include energy absorbing boxes for driver compartments and anti-climbers.

- Shipping Protection: Corex Honeycomb energy absorbers can protect fragile products with minimal impact on the shipping weight, thanks to their high strength to weight ratio.

At Corex Honeycomb, we manufacture different aluminium honeycomb cores by using aluminium alloy grade 3003 or 5052 for different applications based on their requirements. We are also able to offer impact mitigation solutions to customers based on their needs.

- Why is aluminium honeycomb a good choice for energy absorption?

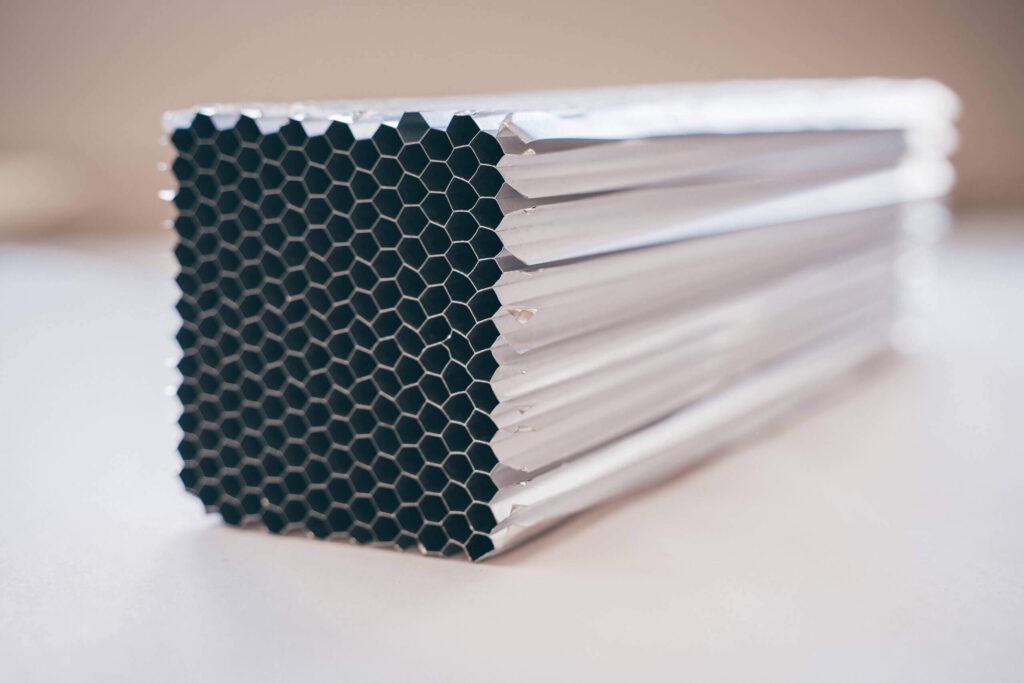

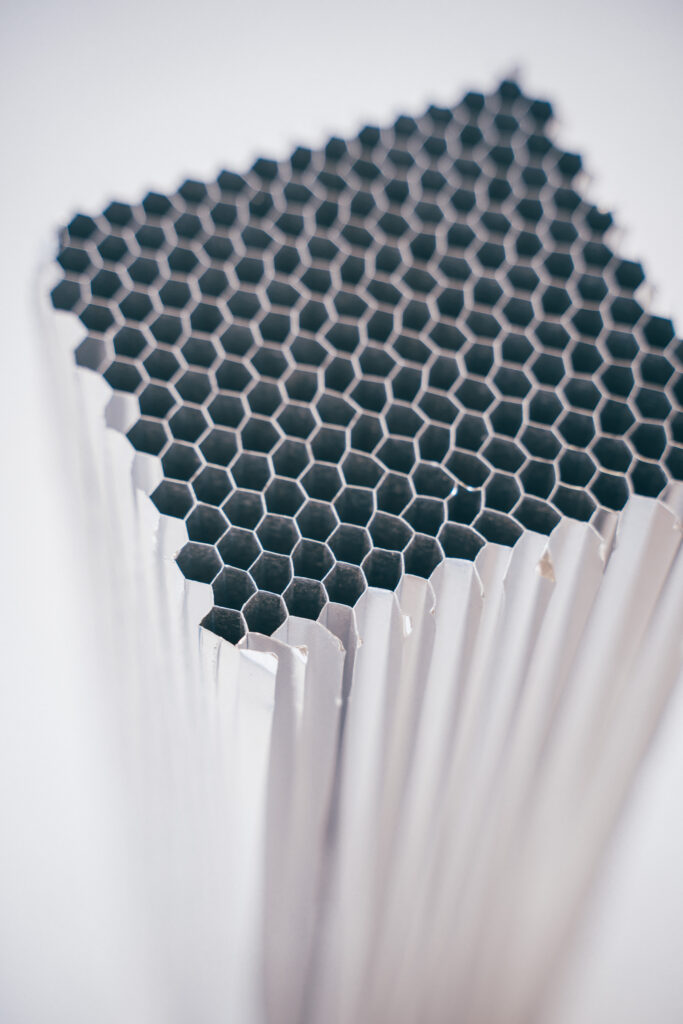

Thanks to the way it is manufactured, aluminium honeycomb has a specific geometry which allows it to deform and absorb the kinetic energy by converting it to internal strain energy. The folding mechanism of the crushing process in honeycomb means it can absorb a high amount of energy within the minimal material used to manufacture it. A strength of aluminium honeycomb is that it has a high ratio of energy absorption capacity in relation to its weight, therefore making light weight absorbers for impact mitigation.

- What are the common processes used to design and manufacture the energy absorber units?

The design of an energy attenuator system generally requires mathematical calculation or finite element modelling, component testing and validation testing. Usually, multiple solutions are provided to clients, who then decide on the final design. Once the design has been selected, a more detailed analysis may be done, and component tests are carried out to validate the performance of the energy absorber. At Corex Honeycomb, we model the customers’ request specifications to ensure the capabilities of the designed system. Manufacturing energy absorbers depends on the material used, the shape, and constraints which are defined by the customer or the application. However, we have a range of in-house manufacturing capabilities that allows us to manufacture different systems regardless of their complexities. An excellent example of Corex’s work with this previously is use of energy mitigation systems in nuclear flask containers, where there is a particular necessity to protect the contents inside.

- What is the purpose of pre-crushing aluminium honeycomb and what is the process?

Pre-crushing honeycomb is required in some applications. In a typical impact loading on a honeycomb block, there is a short-term spike in the level of the reaction force recorded at the very early stages of the crushing behaviour. Although such a high reaction force occurs almost instantaneously, it can exert a high level of G force to the impactor which is not a desirable phenomenon in some applications. This can be relieved significantly by pre-crushing the honeycomb at one end using compressive force exerted by powerful pressing tools under controlled procedure.

- Does aluminium honeycomb offer a variety of crush strengths?

Aluminium honeycomb is available in a wide range of crush strengths. The crush strength of aluminium honeycomb depends on foil thickness, cell size and the alloy used to manufacture it. Corex Honeycomb can also alternate the crush strength by etching the honeycomb in acid.

- Can you explain the concept of full densification in an energy absorber unit?

When aluminium honeycomb crushes, the cell foils fold in and stack up. Once all the un-crushed foil is consumed, the core is referred to as fully crushed and the material is fully densified. Crush strength is higher in fully compacted materials. Depending on the core, the densification ratio could vary between 10-20% in most honeycomb.

- What services does Corex Honeycomb provide to assist with energy absorption requirements?

Corex Honeycomb offer energy mitigation services to different sectors such as automotive, aerospace and nuclear. We provide a full-service including feasibility analysis, design, manufacturing and testing. We use finite element analysis tools such as LS DYNA and Ansys to carry out our analysis. At Corex Honeycomb, we also offer the following test facilities & computer modelling:

- Quasi-Static testing: this includes tests like the Lap Shear, T-Peel, Climbing Drum, Flatwise Tensile, ASTM testing.

- Dynamic Testing: this involves using a Gravity Sled Facility capable of achieving up to 35 KJ of kinetic energy.

Corex Honeycomb are experts in the field of energy mitigation systems and can offer a wide range of solutions for multiple industries and applications, as well as an extensive list of testing facilities. If you have any enquiries about energy mitigation systems, then our in-house engineers are on hand to answer any questions. Also, please contact our sales team if you would like to find out more about how Corex Honeycomb can help with your energy absorber project. To keep up to date with news about Corex Honeycomb, follow us on Facebook, Twitter and LinkedIn.

This article was originally published by Corex Honeycomb.