Holmatro

Discover Holmatro’s World of Rerailing @ InnoTrans 2022

This article first appeared in the Railway-News magazine, Issue 3 2022.

Holmatro – We Help Make the World Move Forward

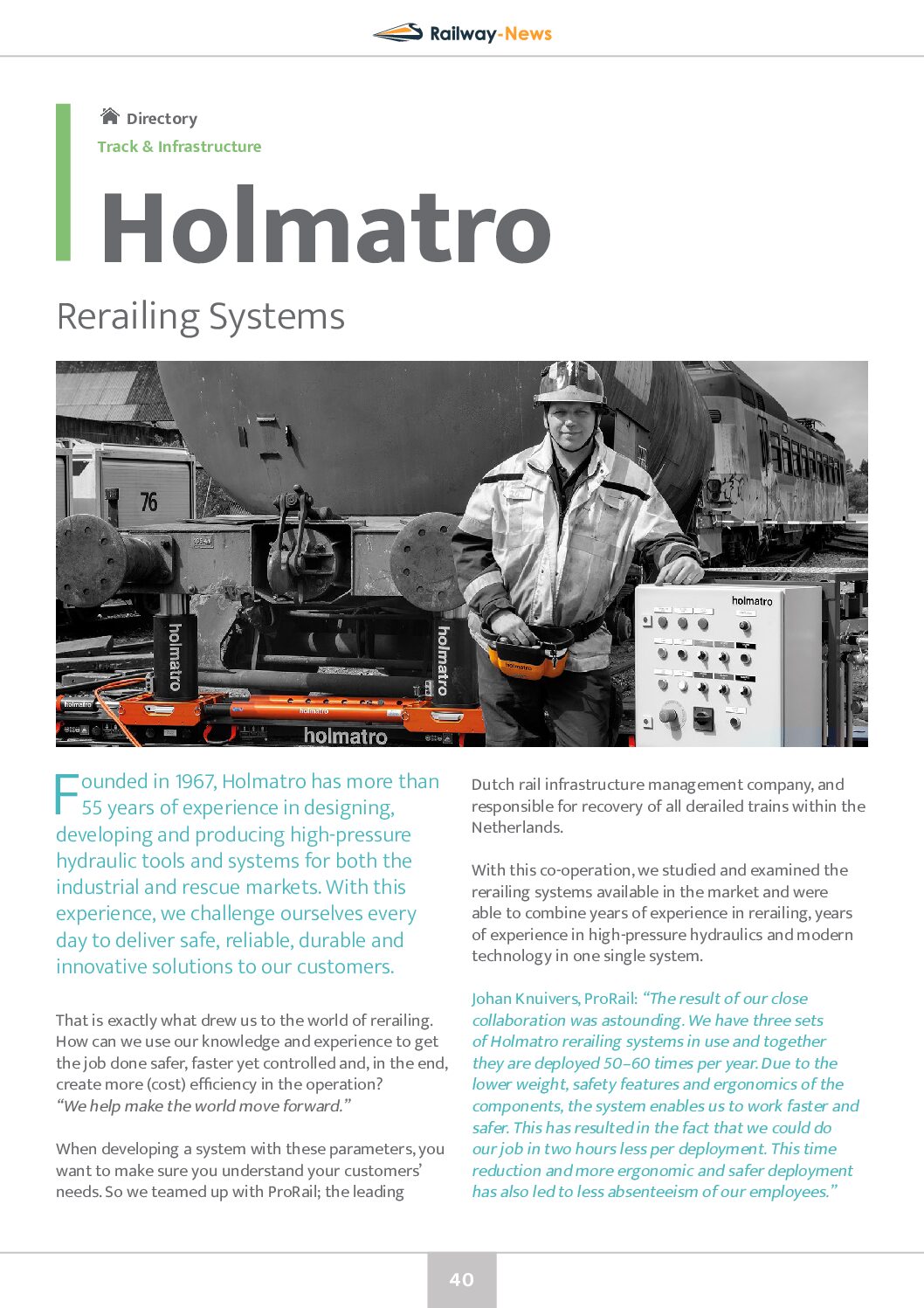

Supporting the green energy transition (offshore wind farms, recycling), enabling civil engineering companies to build roads, bridges or moving buildings, helping to place trains back on track, reducing downtime for production facilities and making working with high-pressure hydraulics safer; in all these applications and many more, our equipment and service concepts are key to helping make the world move forward.

Holmatro products are all about the principle that only controlled power can be deployed effectively. Still, for over 55 years after the foundation in 1967, we keep honouring our traditional Dutch roots and represent innovation, quality and support. That is why we design, develop, manufacture and test our tools in-house. Our experience with high-pressure hydraulics enables us to seek out the boundaries of what is technically possible. This has made our tools lighter, more compact, more durable and easier to use.

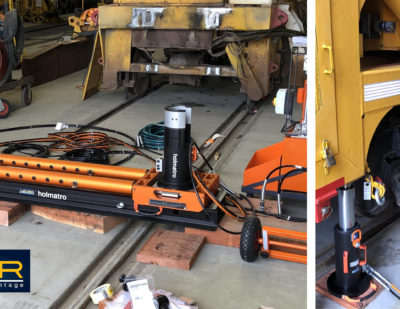

Holmatro’s World of Rerailing

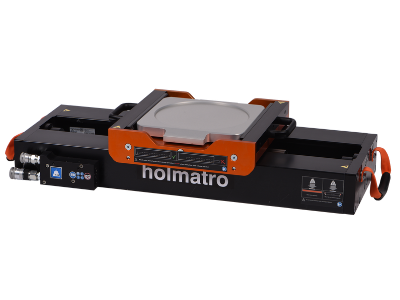

When a railway vehicle derails, the aim is to have the vehicle back on track as soon as possible in a safe and controlled manner. It is important to have a system in place that can do the job. Holmatro offers rerailing systems that are suitable for different rerailing applications.

The Holmatro rerailing systems are built with three main elements in mind:

- safety

- speed

- controllability

Safety

A safer rerailing system speaks for itself simply because the recovery team needs to work in a safe environment. That’s why unique safety features were added to the Holmatro rerailing systems.

Speed

One of the main reasons why a rerailing system needs to be fast is because time is crucial. Especially when the downtime costs can increase a lot every hour the track is blocked.

If you have a system in place which enables operators to work up to two hours faster than other systems on the market, you are able to save a lot of time and money.