By Thorsten Bomke

Market Portfolio Director Services, Alstom

‘Digitalisation’ was one of the most frequently-used words at InnoTrans 2016. The number of announcements or articles published relating to ‘digital’ products has continued to grow ever since. Many of these publications focus on the new technical solutions available today; some focus on the cultural and organisational changes that digitalisation represents for a company such as Alstom; but not enough focus on what this is all about: providing the highest possible train system availability with the most efficient use of resources.

Using data to improve a technical system of any kind represents nothing new for the rail industry. Train systems have been collecting data enabling operators and maintainers to understand and improve these systems for many years. The novelty lies in the quantity of data that can now be made available and managed in real time, and in the correlation of datasets that can be used to create new information and even predict the evolution of system parameters. Technical and cultural challenges need to be carefully addressed to fully benefit from these new developments and to achieve the highest possible train system availability at reduced costs.

Using data to improve a technical system of any kind represents nothing new for the rail industry. Train systems have been collecting data enabling operators and maintainers to understand and improve these systems for many years. The novelty lies in the quantity of data that can now be made available and managed in real time, and in the correlation of datasets that can be used to create new information and even predict the evolution of system parameters. Technical and cultural challenges need to be carefully addressed to fully benefit from these new developments and to achieve the highest possible train system availability at reduced costs.

Market Drivers for Digitalisation

So why have the concepts of ‘Digital Rail’, ‘Rail 4.0’ and ‘IoT’ (Internet of Things) become such buzzwords in today’s rail industry? The rail market is facing strong intra-segment competition, discrediting the predictions of a few years ago, which foresaw a strong concentration of the rail market and a reduction of suppliers; we continue to enjoy a large variety of market actors in terms of geography and technology. Inter-segment competition is also growing: Maglev trains, electric buses, automatic driving trucks and shared individual modes of transport such as Uber are competing with the traditional rail sector. This growing competition in passenger or freight services has an impact on operators. The frame conditions of the rail market can increasingly be compared with other infrastructure markets such as the telecoms or energy sector: markets today are often open to competition, with various actors, both public and private, competing over new franchises for passenger or freight services. Growing competition at all levels of the rail market has placed greater pressure on costs, but it is also stimulating innovation.

Energy is a major cost factor for train operators, representing up to a third of the total operating cost of passenger services, and even more for freight services. Visibility over energy costs and the ability to control energy consumption is a prerequisite to optimise an operator’s cost position. Collecting energy consumption data and monitoring it over a long period of time is therefore essential to identify areas of optimisation and cost reduction.

Other important cost elements are all related to train availability. Train availability targets are achieved when a pre-defined number of trains are ready for service at a given time and location. This objective can be met either with the aid of very large resources (as is still the case on some networks) or by using minimum resources with maximum system availability. Train service availability is ensured through the proper maintenance of trains and infrastructure, requiring permanent investment over the lifetime of the train system. Here as well, knowledge not only of train status, but ofthe systems and subsystems makes it possible to optimise maintenance efforts: how can maintenance cycles be enlarged, how can downtime for maintenance activities be reduced, how can train system availability be maximised? Data thus needs to be collected from trains and infrastructure, then worked with to allow reductions in the life-cycle cost of a train system.

The Technological Push for Digitalisation

We are seeing a growing number of ‘intelligent’ products capable of collecting, analysing and transmitting status data. Additional information can be collected through sensors that measure temperatures, pressures, vibrations or emissions, to name but a few examples here. This makes it possible to add context data to status data. Easily collectable data includes the time and location of a measurement. A wide variety of specialised or combined sensors exist today, and the rail industry stands to benefit from developments observed in other competitive industries. More complex measurement tools such as Motes integrate several types of sensors, thus increasing the quantity of data collected. Motes are networks of wireless sensors specified for the railway environment, enabling predictive maintenance on critical rolling stock components. Motes consist of lightweight versatile components that are connected without cabling and can be configured in various topologies. Data is collected via an array of sensors, then transmitted to neighbouring nodes in order to relay and route all the information to a site maintainer’s tablet computer or to a web-based service.

Most digital services rely on fixed or wireless telecom networks that transmit the collected data in real time. Although the quantity of data per measurement is low, the permanent measuring of a large number of pieces of equipment on trains or at infrastructure level makes it a real challenge to provide sufficiently dimensioned data transmission capacities. Depending on the type of equipment (moving versus fixed assets), various transmission technologies can be of interest. For urban areas, wifi networks represent a cheap transmission mode as wifi chipsets are mass products, meaning costs are low, and wifi coverage can easily be established and the data then sent to fixed networks. In rural areas or when connecting moving objects, radio technologies often rely on 3G or 4G networks to provide cost-efficient coverage over large distances or very high train speeds. The introduction of 5G networks, already begun in some markets, will significantly increase data capacities (maximum data rates: 3G: 2Mbps, 4G: 100Mbps, 5G: 1 Gbps ).

Deploying sensors and communication equipment in areas where additional power supply was not initially foreseen can be a challenge. More and more solutions exist to overcome these challenges, some adapted to rail, and others less suitable. The easiest solution is of course to use an existing power supply, for example one that is used to power trackside products such as point machines, track circuits or level crossings. Installing a power source where no power source has been foreseen, e.g. at bogie level on a train, can be costly. On all moving objects, energy harvesting represents an interesting option; battery solutions have also made great progress with regards to lifetime duration and temperature resistance. Last but not least, data storage and data analytics have evolved dramatically. Data storage centres are either physically deployed in rail projects, or available as a cloud-based service. The processing of huge amounts of data collected in train systems represents a real challenge. Data has to be stored, filtered, analysed, correlated and then turned into actionable information. This is by no means trivial: in the context of rail, the information must make it possible to sound the alert if a measured status is outside a predefined range, as well as predict the status evolution based on historical data so that the ultimate objective, highest train system availability at a controlled and reduced cost, can be achieved.

Prognostics and Health Management with HealthHub

The Alstom HealthHub consists of a series of innovative solutions for remote condition-monitoring and predictive maintenance of rolling stock, infrastructure and signalling systems. HealthHub includes tools for data capturing, transmission and analytics. The ultimate goal of HealthHub is to optimise operational management using a ‘pit stop’ approach: the task chain for maintenance tasks is optimised as events can now be predicted, making it possible to plan interventions. Unplanned downtime for trains or infrastructure can thus be avoided. This means not only having the right parts available for maintenance or repairs; it affects people planning too: which skills need to be available at a given time, and where? What kind of external specialist support may be required? As a result, the train system can improve availability KPIs.

Alstom’s HealthHub™ is Built on Four Pillars:

Alstom’s HealthHub™ is Built on Four Pillars:

- The Motes are a network of intelligent wireless sensors defined by a group of nodes. This network first acquires data, mainly related to vibration and temperature, before transmitting it to neighbouring nodes in order to relay and route the information to on-site technicians through tablet computers or directly to the cloud-based server.

- The TrainTracer is an on-board real-time train conditionmonitoring tool, which could decrease train downtime by up to 30% and recurring faults by up to 50%.

- The TrainScanner takes between 45 and 90 seconds to carry out an x-ray check on a train, and automatically and accurately detects potential maintenance needs for various components and fixed parts.

- The TrackTracer and CatenaryTracer are designed to capture data on track and catenary conditions during operation in order to predict and plan any maintenance.

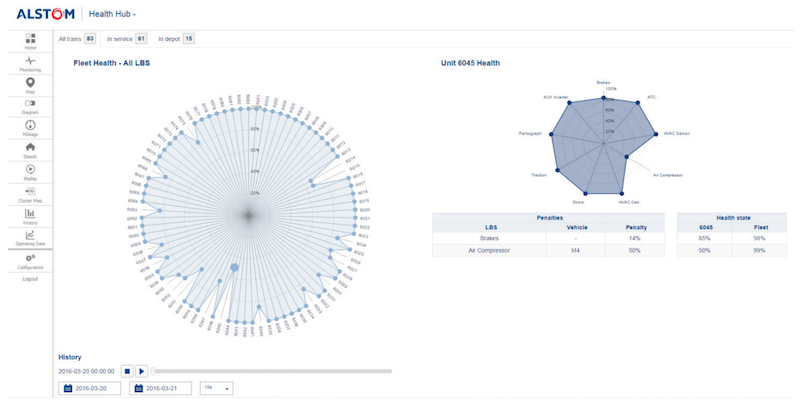

After the data acquisition, data scientists work on analysing the raw data. This step will become more and more automated as time goes on, but the creation of data models still requires human intervention, especially for new systems where PHM methods are applied. The HealthHub algorithms help to predict the future status of a given component, i.e. its remaining useful lifetime. To achieve this, the algorithms use time-series data concerning the asset condition combined with other data such as maintenance history, track profile or even weather data. Maintenance tasks for each asset are anticipated and optimised.

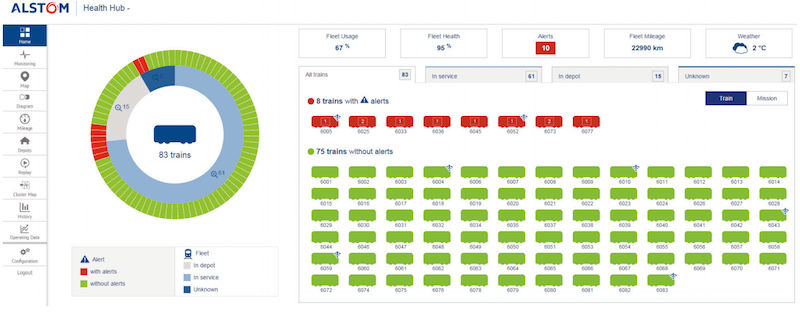

Finally, information needs to be made accessible to the different levels of experts involved: data scientists, maintainers, team leaders, product managers, quality experts, and so on. HealthHub calculates a Health Index for each asset. The current status of an asset (fleet, train or component) is displayed in an ‘at-a-glance’ format to various parties through an ergonomic user interface. The information displayed is customised for each user. The example below shows the fleet view for West Coast Main Line Pendolino trains. The radar view, also displayed below, makes it possible to determine the train’s health on a more detailed level.

Lessons Learned on the Way from Condition-based to Predictive Maintenance

Digitalisation is not an objective in itself. It is nothing more than a tool designed to facilitate, in the context of the rail industry, higher train system availability. However, it is a tool with a significant impact on our way of working. As with any of these changes, it requires all the people involved, at every level, to successfully carry out the project and make it a common success. This requires a clear definition of objectives, information for the participating teams or those affected, and long-term project management. Digitalisation is not a product; it is not a service; it is a cultural change, and has to be managed as such. The journey has just begun – and there is no final destination.

FOR ALL THE LATEST INFORMATION, NEWS, IMAGES, VIDEOS AND DOCUMENTS FROM ALSTOM, PLEASE CLICK HERE.