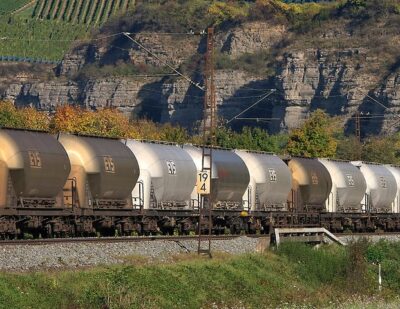

Deutsche Bahn has started using its own large-format 3D printers for the first time in order to make vehicle maintenance easier and faster.

Deutsche Bahn has announced it would be moving into industrial 3D printing for parts and tools for train repair. The company is installing large-format, powerful 3D printers in its maintenance workshops in Nuremberg and Neumünster. Employees will be able to design and print their own tools as well as plastic spare parts for trains.

3D printing was a key technology for DB, the company said, allowing it to have the correct spare parts on hand independent of supply chain issues and raw materials shortages. By using this technology, Deutsche Bahn hopes to increase the availability of its fleet. The company also said that this method was faster, more resource-efficient and sometimes even cheaper than using conventional manufacturing methods.

Deutsche Bahn has printed more than 26,000 3D printed parts for a total of 300 different applications since 2015. 3D printed items range from simple plastic coat hooks to 17kg metal components for ICE trains. Up until now these parts have been printed with outside help. Now, DB is expanding its use of 3D printing and manufacturing more and more of the items itself. As part of this effort, Deutsche Bahn has integrated 3D printing as an integral part of its training programme in plants.

“Our trains should roll for our customers and not stand in the workshop. With 3D printing, we can procure spare parts more quickly and reproduce parts that are no longer available ourselves. It makes me proud when I see how many ideas our employees have developed for the use of 3D printing and are constantly developing new ones.”

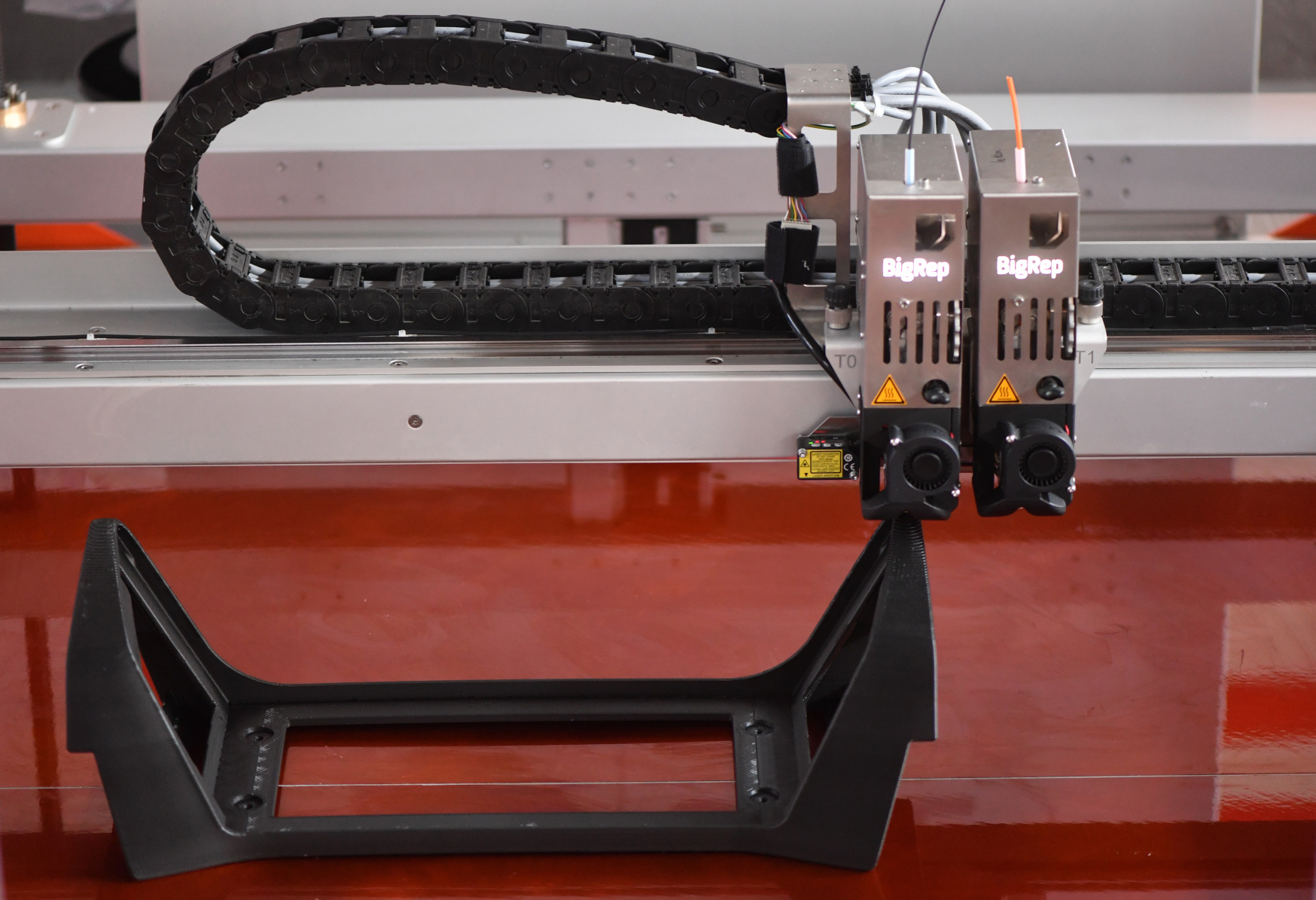

3D Printed Parts: Tools & Aids

In DB’s maintenance workshop in Nuremberg, the state rail operator prints tools and aids that help employees perform their jobs. These include stencils with which pictograms can be affixed or headlights covered when trains are being painted. Consequently these stencils save time by avoiding the need for customisation or masking and they are made from recyclable material.

With the stencils, glueing seat numbers takes three minutes instead of eight. As part of the modernisation programme, the approx. 8,700 seat numbers for all 58 ICE Is to be refurbished in Nuremberg will now take 730 hours less to glue.

Assembly aids are also being printed in Nuremberg. These can make it easier to tighten screws that are difficult to access and that too saves time. Employees are able to submit suggestions for new applications in an internal DB competition.

3D Printed Parts: Spare Parts

In the maintenance workshop in Neumünster, DB will manufacture plastic spare parts for its trains. These include ventilation grilles, handles and covers. Some of these spare parts are no longer available and can only be acquired after a very long waiting period or at high costs. The 3D printing machines in Neumünster can process materials that meet the special technical requirements for components in trains, such as special flame resistance.