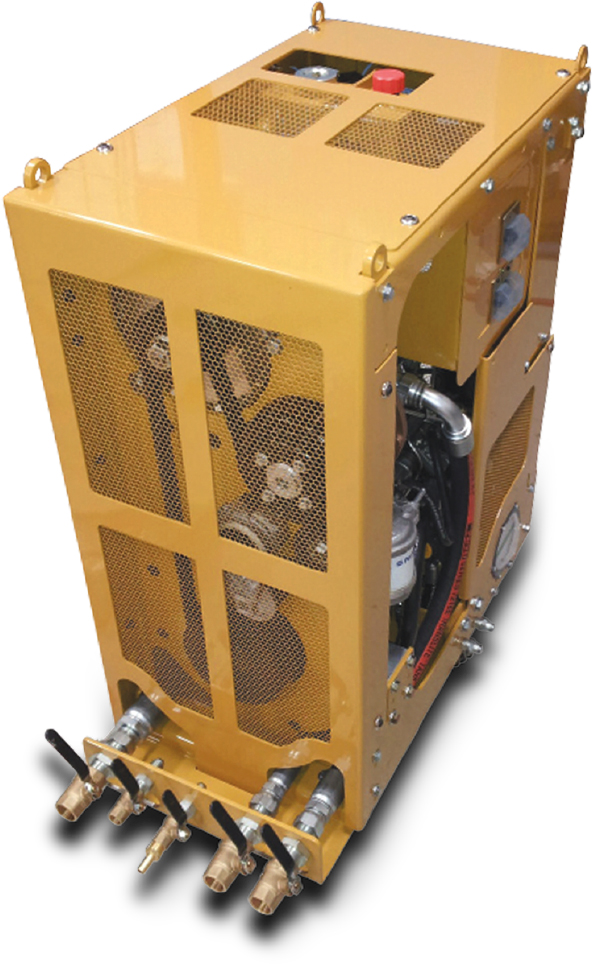

The “Banana” Locomotive Auxiliary Power Unit (APU)

By Michelle De Ruiter

Our proprietary Banana Auxiliary Power Unit is designed to reduce excess idling, save fuel, reduce locomotive engine wear and souping, and meet local noise ordinances; all while keeping your crew comfortable, a true win-win for everyone.

The US EPA Tier-4 compliant model has been re-engineered in order to meet ever-tightening emissions standards, yet still maintains the required locomotive life support systems. When the locomotive is shut down the APU charges the locomotive batteries, warming the locomotive coolant and oil.

Specifications and Features

The Banana’s CAT/Perkins diesel engine is governed at 2,800 RPM. The engine drives a 130A, 72 VDC (11 kW) generator that heats the locomotive coolant and lube oil, charges the batteries, and can be used to power cab heaters, lights and air conditions, ensuring your crew’s comfort.

The Banana includes an advanced control system complete with adjustable on/off locomotive water temperature and battery set points, and is CAN bus communication enabled.

Engine: Perkins 400 Series 3 Cylinder Diesel. 28 hp@2800 rpm; Tier 4; Low oil pressure and coolant over-temperature shutdowns. Life expectancy: approximately 20,000 – 24,000 hours with proper maintenance. Tier 4F engine includes a “High Altitude de-rate controller” derating the engine at very high elevations.

Lubrication System: 6 gallon oil capacity with oil level maintainer and filter.

Electrical System: 130A, 72 VDC generator for locomotive loads: 40A, 12VDC APU alternator for APU loads.

Fuel System: 12 VDC electric fuel lift pump.

Cooling System: Glycol base APU cooling system; cooled via liquid to liquid heat exchanger using locomotive water.

Locomotive Engine Water Heating System: 12 kW via 72VDC heater and smart waste heat recovery.

Locomotive Engine Oil Heating System: 4 gallon/min circulation via APU driven pump through liquid to liquid heat exchanger.