Situated along Corridor X near the border with Croatia, Dobova is a small town with a big role in freight wagon maintenance.

As our go-to depot for large-scale maintenance and overhauls on freight wagons, the workshop in Dobova is VPI-certified and went through a number of upgrades in the past years.

Certificates issued by reputable certification bodies demonstrate the importance we place on delivering quality services and meeting your expectations. A number of important improvements have been achieved recently with respect to technology and environmental protection.

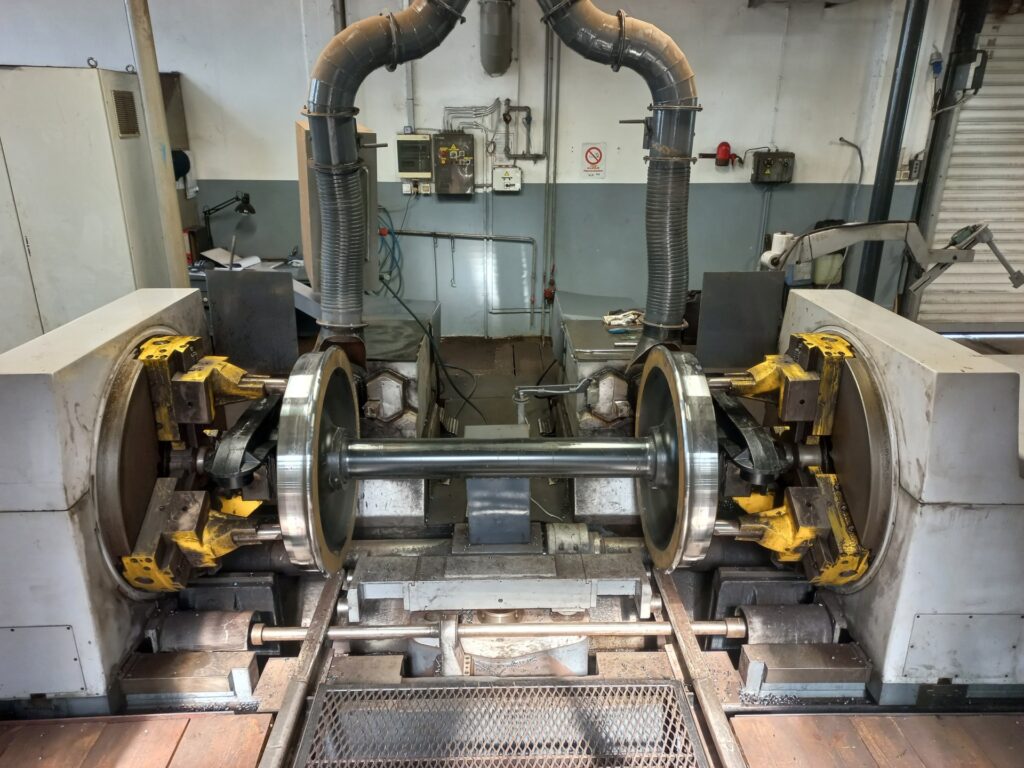

We have recently overhauled the Rafamet UBB 112/2 lathe for wheelset reprofiling. The lathe was fully dismantled and shipped to an overhaul supplier. In the meantime, we rebuilt the foundation of the lathe in Dobova. After the lathe was overhauled and the foundation rebuilt, we purchased a conveyor belt to automatically remove metal chips from under the lathe and discharge them at a container.

We also purchased another lathe for reprofiling wheelset journals and axles, which we installed next to the refurbished lathe. The lathe is a second-hand Potisje ADA PA-50/4000 unit, which was completely refurbished and upgraded with a custom Newall measuring system. Journal and axle machining is a new service at our shop in Dobova, so we also obtained the relevant VPI certificate for the service. With these lathes, we are able to deliver complete IS1 and IS2 wheelset overhauls.

Recognising the growing demand for complete brake inspections on freight wagons, Dobova has acquired an additional automatic brake test unit. After some market research, we decided to purchase the Pdr 7 RailTab brake tester from DB Fahrzeuginstandhaltung GmbH Werk Fulda.

The Dobova centre has renovated its paint chamber to comply with environmental standards and to keep up with the end-of-life of the equipment. The renovation included major maintenance work.

To improve working conditions during winter and ensure more environmentally friendly heating practices, we have recently renovated our heating system by transitioning to an automated boiler house, which is one of the most advanced systems available in the market.

These upgrades add value to the maintenance of freight wagons in Dobova, but they are not the end of our modernisation efforts. To keep up with the needs of our customers, we need to continuously evolve and adapt. To maintain our reputation as a reliable maintenance partner, we strive to anticipate the needs of our customers and continuously update our facilities to align with the latest standards.

This article was originally published by SŽ – VIT.