In this interview, the Trimble team sat down with Andreas Boldt, a surveying engineer at Wayss & Freytag Ingenieurbau AG, to discuss his role, the company’s focus and their experience with T4D Rail, an add-on module from Trimble 4D Control (T4D) monitoring software.

Andreas shared his background, detailing his responsibilities in overseeing surveying projects and the company’s specialization in civil engineering, tunnel construction and infrastructure projects. He also provides an in-depth look at a significant project—the new construction of the BAB (Bundesautobahn, EN: Highway) A281 Weser crossing, which is a major infrastructure project in Germany—highlighting the challenges and successes encountered while using Trimble’s advanced rail monitoring solutions.

Join us as we explore the practical applications and benefits of T4D Rail in modern construction projects.

Trimble: Can you give us some background information about who you are, what you do and what the company does?

Andreas Boldt: I work for one of the oldest construction companies in Germany, Wayss & Freytag. I am responsible for improvements and supervise all the surveying projects in central Germany. Wayss & Freytag primarily focuses on civil engineering, tunnel construction and infrastructure construction.

We handle many major projects, such as the Weser crossing, which is worth 800 million Euros and is being implemented solely by us. This is a significant project.

Trimble: Can you tell us about the project where you used T4D Rail?

AB: Yes, in this project, we are constructing the Weser crossing to help revitalise Bremen’s economy. A reliable transport connection is crucial—without it, businesses will struggle, and the region risks losing companies. Ensuring smooth infrastructure is key to keeping Bremen economically strong and competitive.

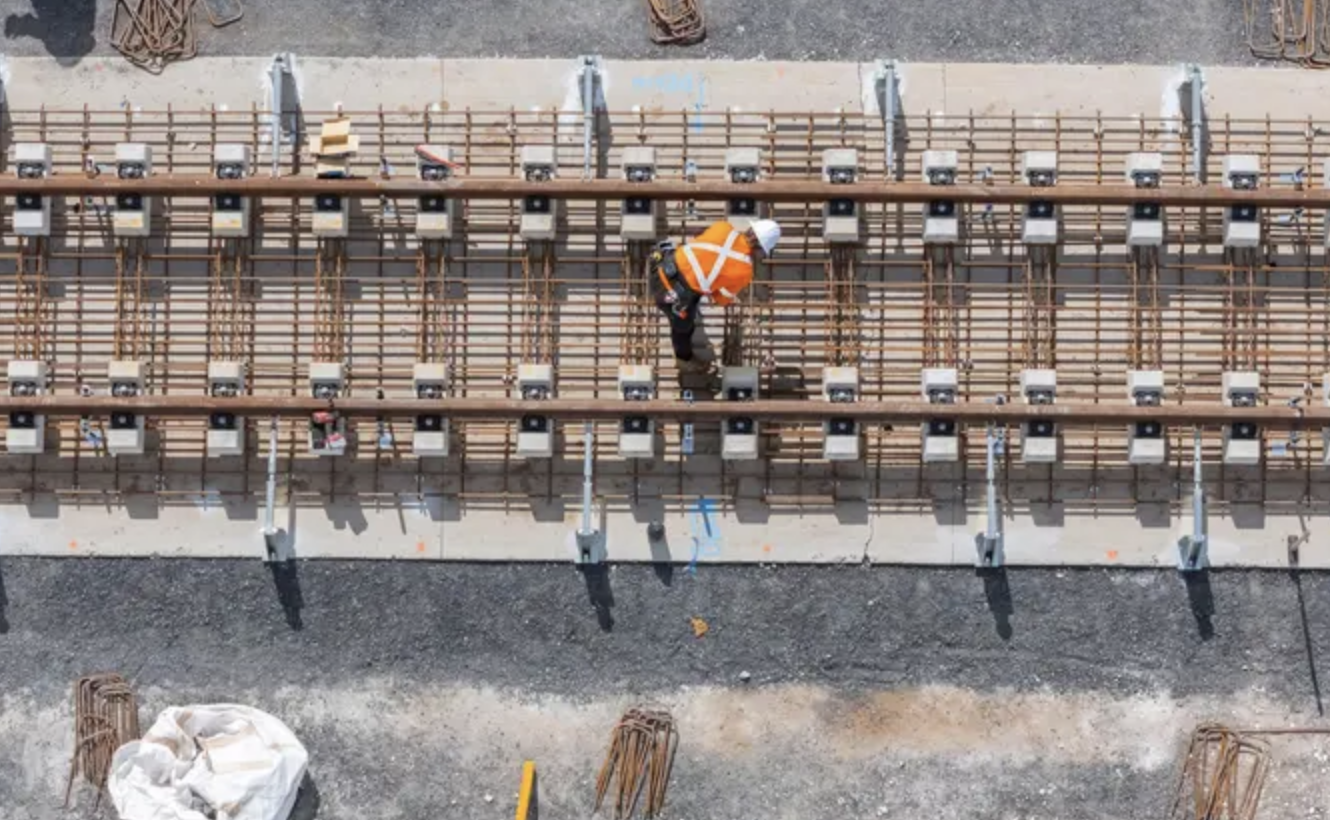

The project encompasses a five-kilometre stretch of highway, of which approximately one and a half kilometres is a tunnel. The client for the highway tunnel is DEGES (Deutsche Einheit Fernstraßenplanungs- und -bau GmbH, EN: German Unity Highway Planning and Construction Company). The construction contract includes the construction of different engineering structures, as well as road construction and other structures. The tunnel is partly built using open construction, and the main part, about 800 metres, is floated in. We build the prefabricated tunnel elements in the dock in Bremen port, float them out, temporarily store them in Bremen, and then float them into the Weser and position them. The rail monitoring part is crucial, especially since the tunnel goes under the Hanse-Bahn marshalling yard which is part of the local steel mill.

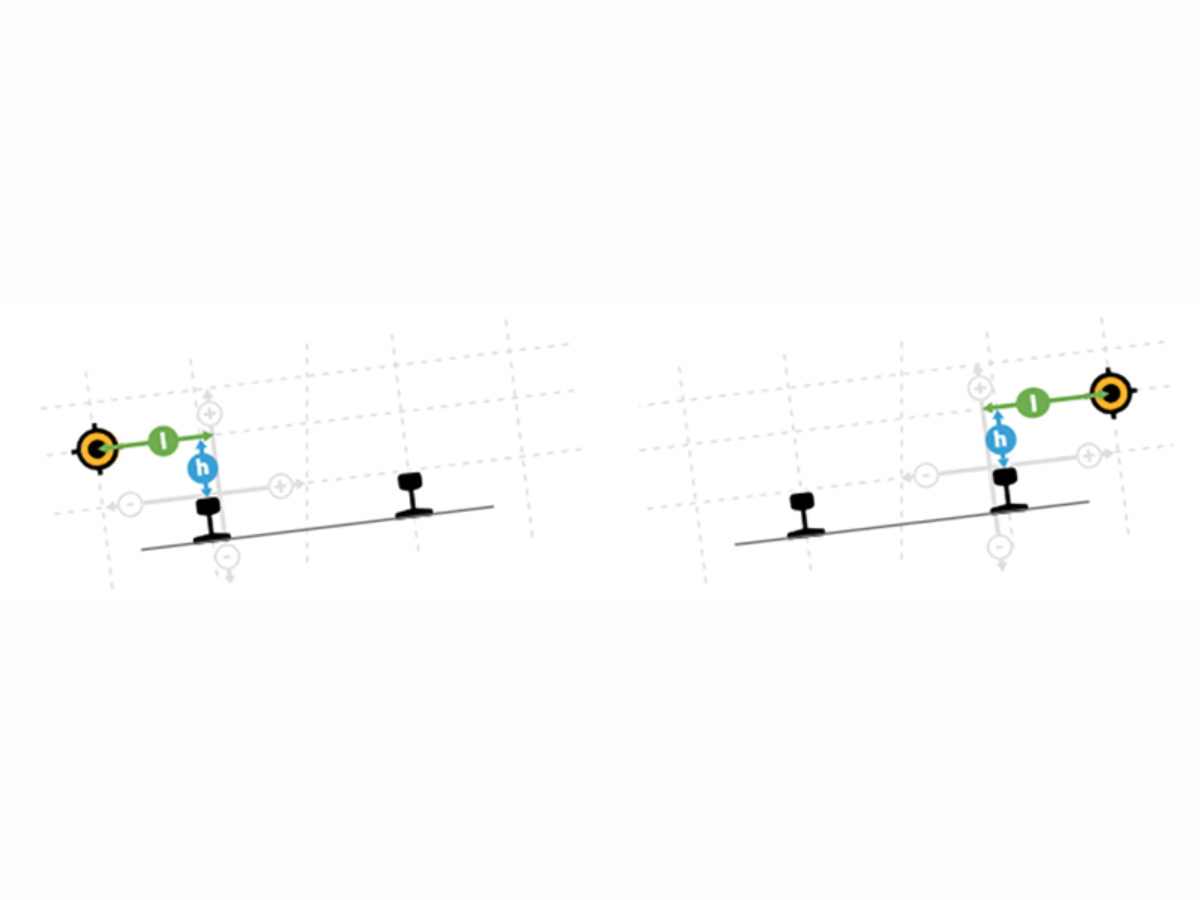

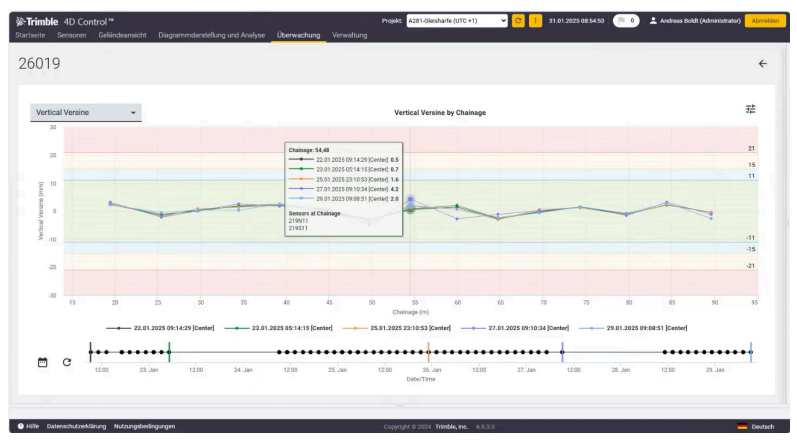

More specifically, the area [Marshalling yard], between km 3+750 and 3+850, is where the existing track group (from track 6017 in the north to track 6025 in the south) is directly impacted by the construction work. As part of the movement and deformation monitoring, the operational railway tracks will be continuously observed using a permanent monitoring system. The first phase of the project will focus on monitoring three tracks, with the remaining three to be added in the second phase.

Trimble: How did you hear about T4D Rail?

AB: I’ve been working with T4D for a long time, and when this opportunity arose, I thought it was a perfect use case for it. I am using Trimble equipment and trying to stay up to date with the new things Trimble is bringing to the market so I was familiar that T4D Rail exists.

Trimble: So the reason why you used T4D Rail?

AB: We have a lot of Trimble equipment, so it was a natural choice. I also watched some webinars beforehand, which convinced me this solution would get the job done.

Trimble: Did you do rail monitoring before?

AB: Yes, but manually. It is not always the case that an automated system is needed so we had some semi-automated monitoring projects in the past. I leveraged the Trimble Business Center monitoring module for these types of projects to speed up the work. I was always on construction sites and assigned to monitoring.

Trimble: What challenges have you had with the project?

AB: The track is not electrified and there was little existing development, making it difficult to set fixed points. We built two fixed measuring pillars for reasonable survey points and added cross anchors into the ground with prisms on top.

Trimble: How was it in the beginning? You already knew that T4D Rail existed.

AB: I watched a webinar and quickly glanced over the operating instructions. It was simple to work with after that. And in my opinion, there should always be some kind of documentation for the software but to be honest, [the] T4D Web [module] is really intuitive and when you want to see how something works, you test it real quick and you are ready to go.

You can start without documentation and test it by clicking around.

Trimble: You have probably seen that there are different workflows in T4D Rail. You chose the workflow with the as-built survey?

AB: Yes, we used an as-built survey workflow. We measured the track, placed the prisms, but unfortunately, since there was railway traffic happening, a lot of prisms got destroyed. They also decided to tamp two tracks so we had to repeat an as-built data survey but after that we were able to set it up and the monitoring system is up and running.

Trimble: And how did you do that?

AB: I used the [Trimble Access] Track Gauge Survey app. That’s the easiest way to do it. This was my first time using it and it worked well. The software provided guidance.

Trimble: Do you think that other Trimble products have improved the workflow? I saw that you have a Trimble SX10 total station.

AB: Yes, I have the SX10 and SX12. I initially used them for scanning but now use them as total stations. They are great.

Trimble: Is there anything in T4D Rail that you particularly liked?

AB: I liked the automated calculation of all important rail geometry parameters and the ability to specify a prefix for searching prisms. But the biggest highlight is the system’s simplicity. The software finds the points effectively, which saves time.

Trimble: Have you had any positive effects that you didn’t expect when you started the T4D Rail project?

AB: As an experienced T4D user for over 15 years, I expected a positive outcome from the newest add-on module T4D Rail. And no surprise, it delivered the values I wanted.

Trimble: Would you recommend T4D Rail to others? And if so, why?

AB: Yes, definitely, because of its ease of use and the fact that it delivers what you need.

While all rail infrastructure projects vary based on requirements and need, the Weser crossing project highlights the importance of reliable transport connections for economic stability. In this context, T4D Rail offered an automated monitoring system that replaced previous manual methods, potentially increasing efficiency and accuracy. The software’s ability to deliver necessary data and its ease of use were key factors in its adoption.

For more information about Trimble 4D Control (T4D) monitoring software and its applications, please visit the Trimble 4D Control Rail to learn more.

This article was originally published by Trimble.