Leading Management Services for the Rail Sector

Leading Management Services for the Rail Sector

TRIGO is the global leader in quality management services for the automotive, aerospace, railway, and heavy transportation industries. With 10,000 employees in 28 countries, TRIGO offers a comprehensive portfolio of services throughout the supply chain, from production inspection to audit, consulting, engineering, and training. TRIGO develops technological solutions based on artificial intelligence, virtual reality, battery management, and data analysis.

TRIGO’s quality solutions vary from corrective to preventive actions. They are meant to avoid potential quality nonconformities during manufacturing processes and to maintain smooth and error-free production in the Automotive, Aerospace and Heavy transportation industries.

The unrivaled expertise, industrial mindset and extensive global footprint that TRIGO has built up over the last 3 decades has made TRIGO the leading quality solutions provider using the latest innovative and reliable digital systems and standard processes, delivering results in the most demanding industries. For example, TRIGO has supported the global electrification of vehicles since the first modern electric & hybrid vehicles were produced.

Our mission in the Rail Industry is to optimize performance and quality throughout the supply chain, mirroring our approach in other sectors. Since 2010, we have focused on quality control and rework services for ALSTOM in France, with Incoming Inspection remaining a key foundation of our services.

Over the years, we have significantly broadened our scope. Today, our expertise includes:

- Non-Conformities Management Solutions: We address quality and delivery issues through 8D or QRQC methodologies, ensuring swift resolution and prevention of future occurrences.

- Supplier Development Services: This includes resident engineering, audits, capacity assessments, First Article Inspections, and training on essential quality tools.

- Manufacturing Support: Our services extend to mechanical and electrical maintenance operations, Non-Destructive Testing (NDT), and rework of parts to ensure they meet the highest standards.

In 2024, our teams work directly in over 20 rolling stock manufacturing sites and over 100 key suppliers in the rail industry worldwide. We have performed a +30% growth since 2023.

Purpose

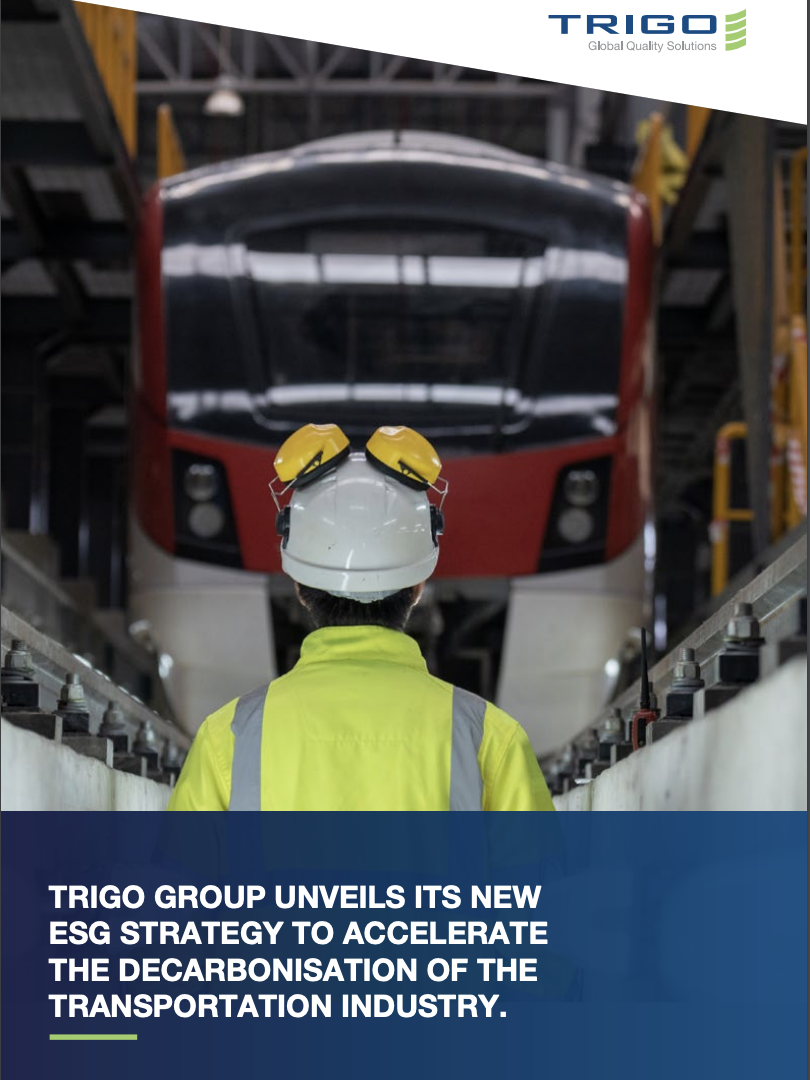

At TRIGO, we firmly believe that high quality is essential to industry performance and sustainability. Without quality controls and an effective preventive approach to quality, there is no sustainable production for the industry.

Not only does quality reduce costs by decreasing time to market, it also promotes human safety by preventing accidents with potentially serious consequences.

By avoiding non-conformity through preventive actions, and by controlling and correcting defects when they occur, we contribute to safe industrial production with improved economic performance.

Vision

From our purpose flows our vision. If quality is essential in the world and in particular for the industry, we believe that delivering a world class quality is the result of the joint and adapted action of skilled men and women, as well as proven processes and technologies.

That is why we concentrate our efforts in these three areas. In addition to the technical dimension, our success is due to our teams, who are committed to deploying solutions that optimize the performance of industry and supply chains on a global scale.

Mission

As quality experts, we are also increasingly committed to helping our customers reduce their carbon footprint. With this goal being a major concern for the entire industry, we believe that as partners we have a role to play in helping address this issue. This is the meaning of our quality management solutions we deploy, which optimize manufacturing and supply chain performance, globally. These solutions enable us to reduce scrap rates, as well as the volume of waste generated on production lines. Increasingly, we are helping our customers to achieve these objectives through tailor-made solutions and our innovation strategy. Every year, our 10,000 employees inspect and rework 1 billion components and vehicles for our customers in 550 plants.