Rail and Switch Point Heating

Switch Point Heating ORIGO Ltd. Has been working for an ultimate way to heat rail and switch points for more than 30 years, using feedback from our customers; adapting their knowledge and desires for improvements to our products. Our goal has been combining functionality with easy handling, installation, bringing down power consumption and at the same time increasing function as well as safety.

Power Saving Heating Elements

Our solution for switch point heating uses a technique where all rails are heated with low power elements, instead of heating two rails with high power to get a heat transfer by radiation from support rail to moving rail. To us, this seems like throwing away expensive electric power.

By keeping rails at a temperature just above 0°C during season when snow and ice can hazard security in railway traffic, installed power can be kept low and temperature regulation is combined with a snow sensor overriding temperature control, at precipitation in combination with temperatures below +3°C.

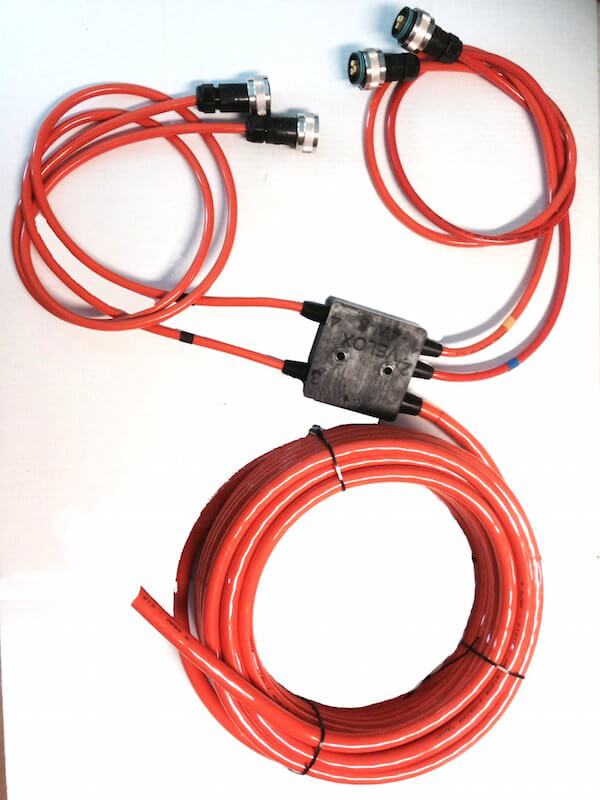

Our system brings possibility to heat all rails with a minimum number of connection points. It´s possible to double or triple power output at sensitive areas locally with multiple elements connecting to end of stock rail element with a quick junction.

Flexible Heating Elements for Rail

Self-limiting Elements (max 130W/m) are easy to transport and handle, delivered as a coil with only a few kilos weight. Elements length can be adjusted on site with simple tools and are easy to install with supplied details. The self limiting function in the element prevents element from burn out.

Elements are delivered as customised ready-to-use units or cut-to-length units. Elements are installed at rail with stainless steel channels and spring steel clips with various sizes for different rail types.

Smart Control Panels

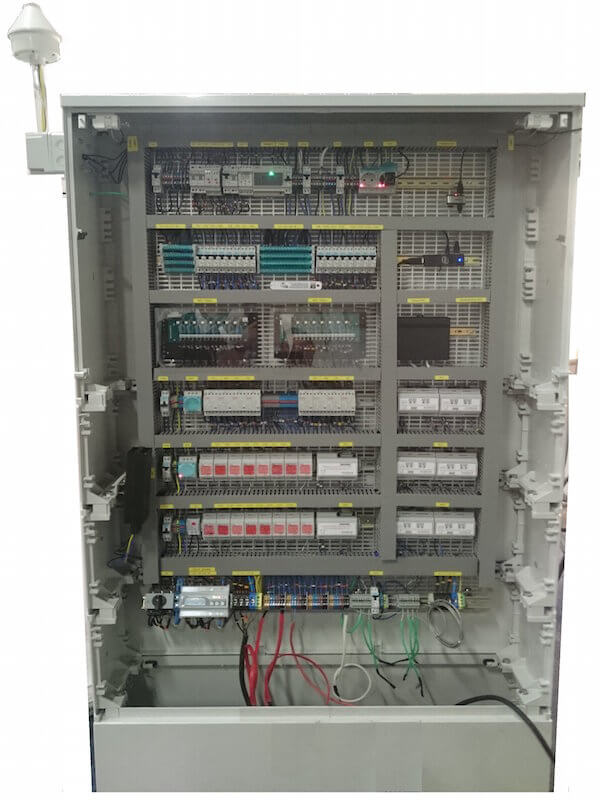

Computer controlled triac based control panels are module built for easy extension, with a built-in touch screen computer (one master panel can control several slave panels).

Control panels can be remotely accessed by intranet, internet or modem and parameters can be changed, logged values for current, temperatures, errors, power-on, presented as diagrams or downloaded for further processing in Excel.

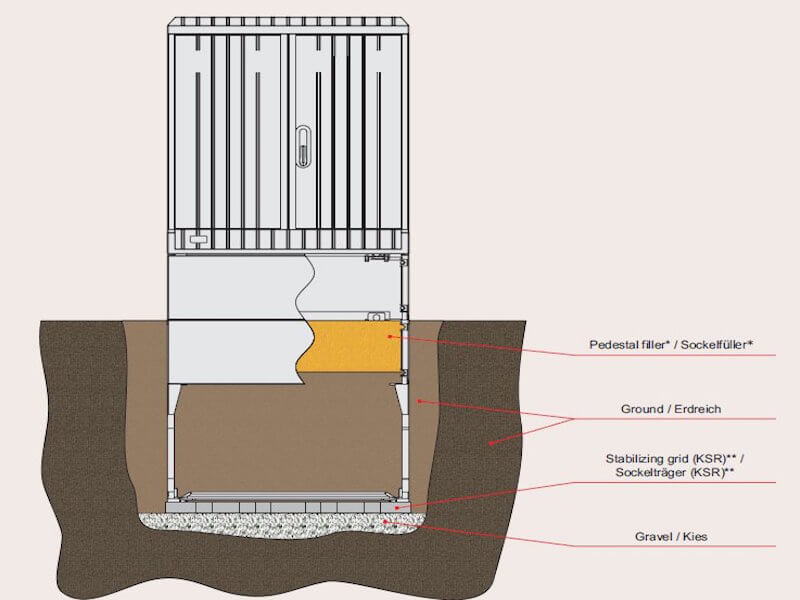

Elements are monitored separately for all errors and alarms can be sent via SMS or internet for instant alert of maintenance personnel at fault. Standard enclosures are made using fibreglass reinforced plastic with integrated dig down ground stand, with the option of steel or aluminium if needed.