High Quality Plastic Sheets and Films for Thermoforming

SENOPLAST stands for high quality plastic sheets and films. Founded in 1956 the company has produced for more than 60 years extruded plastic sheets and films for thermoforming used worldwide in the various industries. Over the years the company has grown into a specialist for the coextrusion process and has become known as the technological leader in this field.

From its Austrian headquarters in Piesendorf, SENOPLAST provides customers around the world and from all kinds of industries with senosan® products. The plastic sheets and films established under the trade mark senosan® are not only used in the automotive and transportation industries but are also well-known for excellent quality and brilliant surfaces in the sanitary and furniture industries.

In 2000 an additional production location opened in Querétaro, Mexico, which meant that customers in the NAFTA area could be served quicker and more efficiently. The 3rd global production unit started production in May 2020 in Suzhou, China.

SENOPLAST has enjoyed global success with innovative and high quality plastic sheets and films made of ABS, ABS/PC, PC, ASA, PMMA and PS as raw materials including flame retardant materials.

SENOPLAST is certified according to ISO 9001, ISO 14001 and EMAS and besides quality and innovation environmental protection is the third main cornerstone in the philosophy of the company, nearly all senosan® materials are 100% recyclable. The senocircle system implemented by SENOPLAST ensures a nearly waste-free production process. The recycling concept ensures that waste material, occurring during production and processing, is milled and integrated to a certain degree in the production process. Worldwide environmental pollution is rapidly increasing, therefore it is part of the annual company goals to increase the percentage of use of recycled materials.

The company SENOPLAST is part of a greater whole, it belongs to the Klepsch Group which employs around 940 people worldwide and processes more than 50.000 tons of raw material per year, achieving an annual turnover of approx. 280 million euros worldwide.

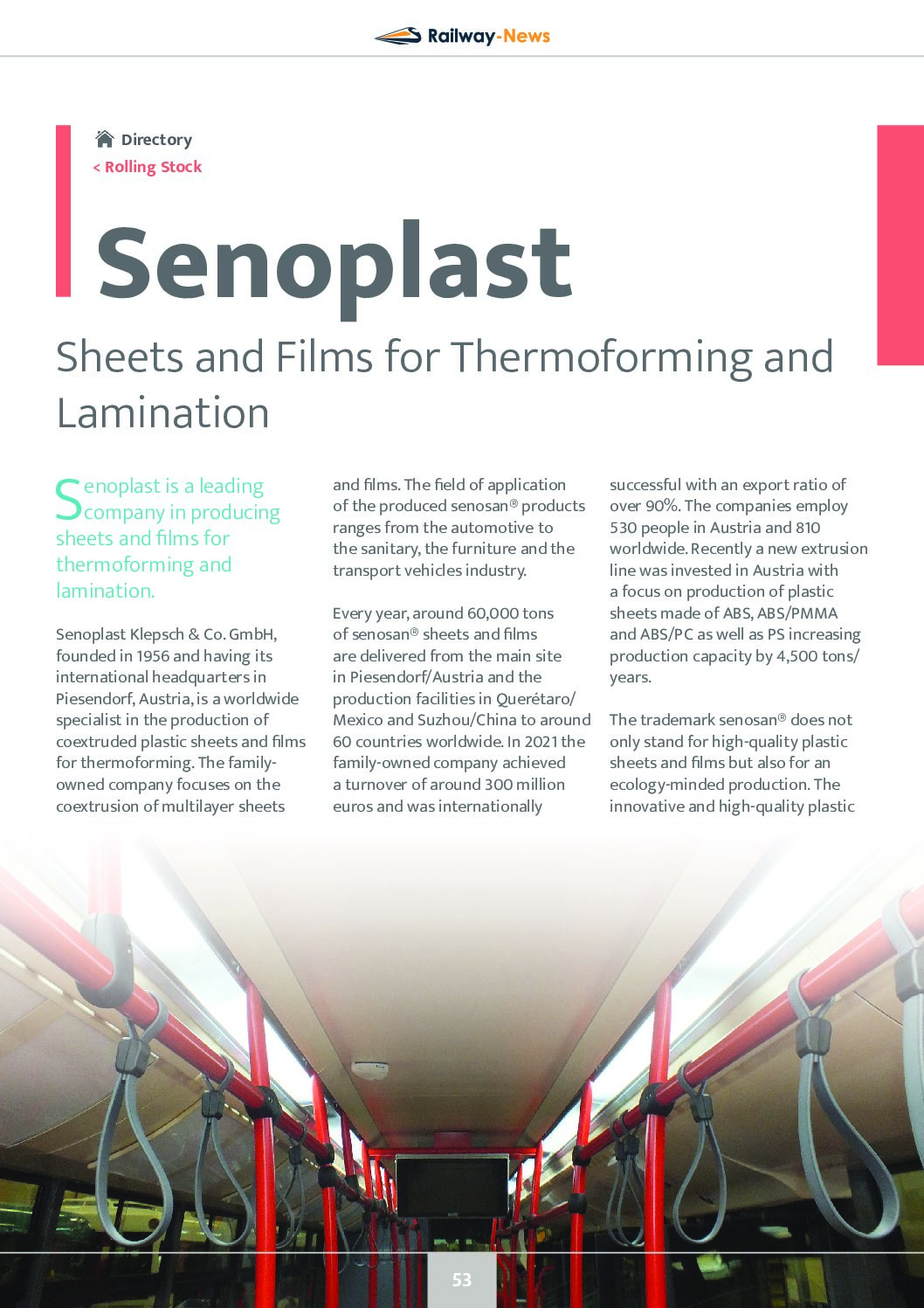

NEW PRODUCT for Interior Railway Applications: senosan® C60FR-5

A flame retardant coextruded PC/ABS-sheet with a matt surface for railway application R1 with HL2 classification according to EN 45545.

Advantages:

- flame retardant, halogen free

- matt appearance

- ductile breaking behavior (no shiver)

- good recyclability

- chemical resistance

- good insulation properties

Product details:

- high thickness range from 2 to 5 mm (R1 HL2)

- Surface: smooth / embossed, various colors

- Material has low density – only 1.3 g/cm3

- Heat deflection temperature of 105°C

- High Impact strength

- Material is released Docket 90-A and NFPA 130

Possible Applications

- Ceiling and side panels in rail vehicles

- Wall cladding

- Roof panels

- Seats