The Key to Rail Depot Safety is FirstClass Safety & Control

At FirstClass Safety & Control Ltd (FCSC) rail depot safety is the core of our business. We are focused on supplying bespoke affordable Depot Protection Systems (DPS) and Depot Control Systems (DCS) that are adaptable to meet an individual depot’s requirements. Our mission is to provide the worldwide rail industry with the safest solutions on the market which is why we go the extra step to provide Safety Systems with a Safety Integrity Level (SIL). To show our commitment to the industry we achieved the maximum 4* RISQS Accreditation first year. By using the latest technologies, a comprehensive range of components and a wealth of knowledge from a range of industries this enables us to develop custom-made systems and bring a fresh open-minded approach to our solutions and to the industry.

All control and safety systems receive our superior customer support via our professional aftersales customer care team, who provide a full service reassuring you that your depot will receive the prompt support you need.

FCSC was established following a management buyout of the control system division of Beck and Pollitzer in 2017. However, the team has been working together since 1998 and build on the quality, experience and expertise to offer innovative rail safety solutions. Our engineering and manufacturing office is based in Essex, UK however, we offer national and global support.

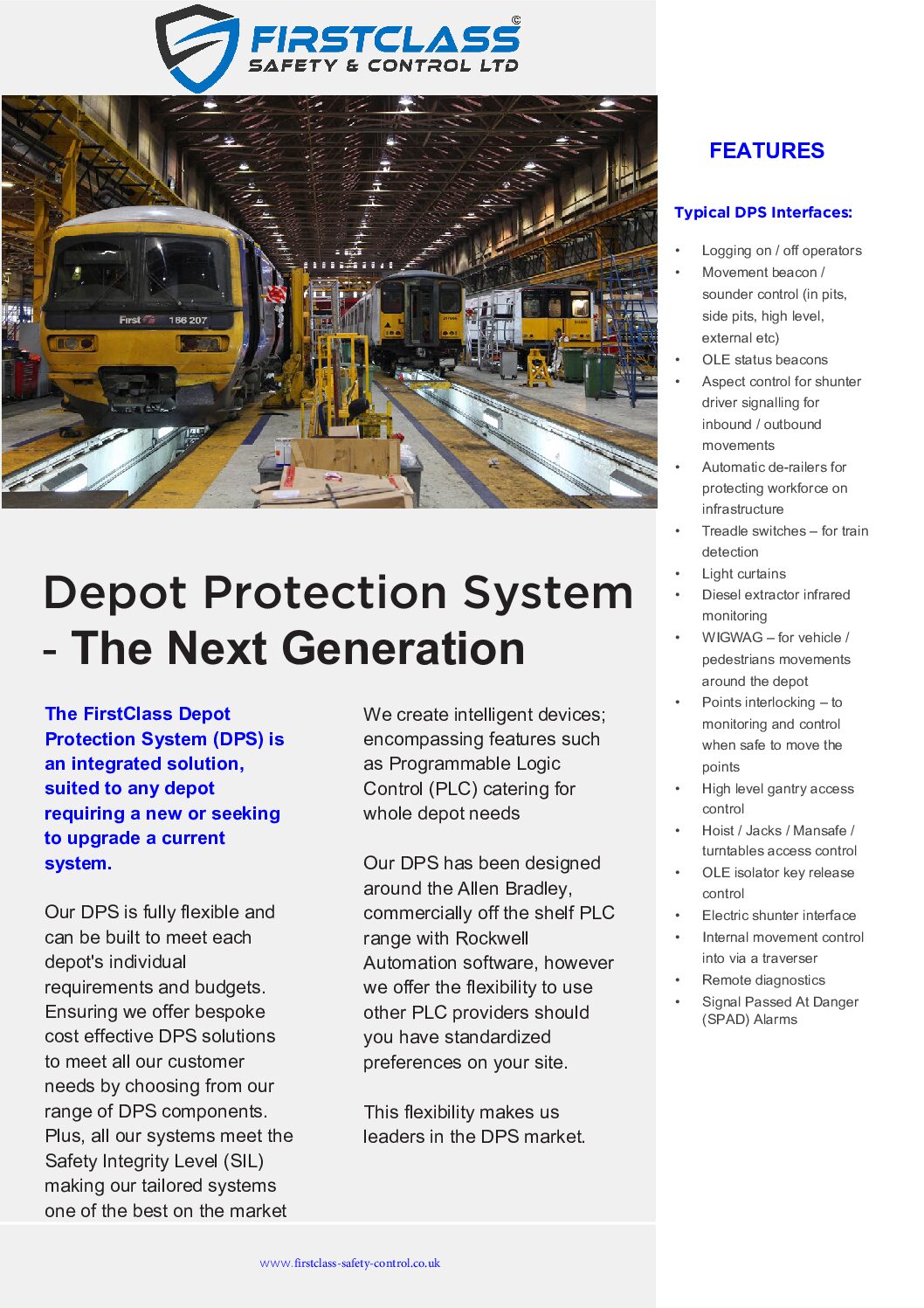

Depot Protection Systems (DPS)

FCSC’s DPS is the next generation in depot protection systems, offering high performance and reliability. It is an integrated solution, suited to any depot requiring a new or seeking to upgrade a current system. Our DPS has been designed around the Allen Bradley’s, commercially off the shelf PLC range with Rockwell Automation software, however we offer the flexibility to use other PLC providers should you have standardized preferences on your site. All our systems including our DPS can meet the required Safety Integrity Level (SIL) making our tailored systems one of the safest on the market

Key features include:

- Logging on / off operators

- Movement beacon / sounder control (in pits, side pits, high level, gantry, external etc)

- OLE status beacons

- Aspect control for shunter and train/tram driver signalling for inbound / outbound movements

- Automatic de-railers for protecting workforce on infrastructure

- Treadle switches – for train detection

- Light curtains for specialist pit protection against accidental shunter movements

- Automatic Diesel extract interlocking

- WIGWAG Signals – for vehicle / pedestrians’ warnings around the depot

- Points interlocking – to monitoring and control when safe to move the vehicles

- High level gantry access control and safety bladders

- Hoist / Jacks / Mansafe / turntable interlocking

- OLE isolator key release control

- Electric shunter interface

- Local Internal depot movement control technology

- Remote diagnostic capability for support services

- Signal Passed at Danger (SPAD) Alarms

A FCSC DPS is a flexible system offering many benefits to the depot and rail personnel including:

- SIL rated- safety reassurance

- A safety system that protects both the infrastructure and people

- Can interlock all aspects of plant and machinery within the depot

- User friendly and built for the depot environment

- An automated system that uses RFID technology

- Utilises ‘off the shelf’ technology (no bespoke OEM requirement)

- Adaptable to meet all applications

- Cost effective over current market competition

- Easy to Maintain and Operate

- Components widely available

- Open architecture, protocol software for easy integration

We have a proven track record for quick and cost-effective maintenance support for repairs/upgrades and call outs for our DPS and also emergency support on other OEM supplied DPS Systems and equipment.

De-railers

At FCSC we have acknowledged that there is a limited choice of De-railers which are often expensive, not 100% safe and have long delivery times. Therefore, we have developed our own De-railer, offering our customers more choice and better value. Our De-railer was designed to be the safest on the market as we monitor “head position” not “actuator position” therefore eliminating any failure points and with the option to detect vehicles using ultrasonic or infrared laser technology.

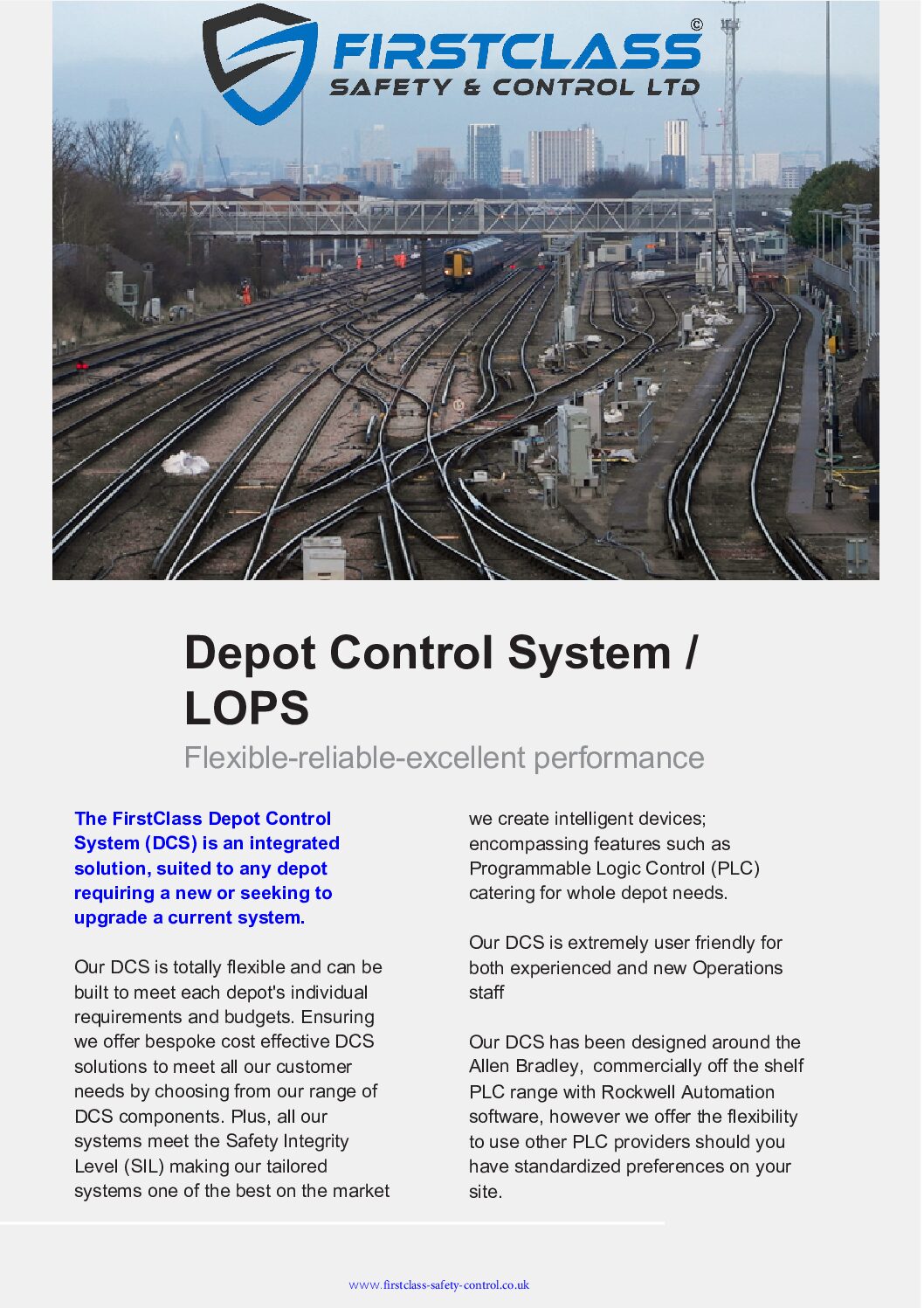

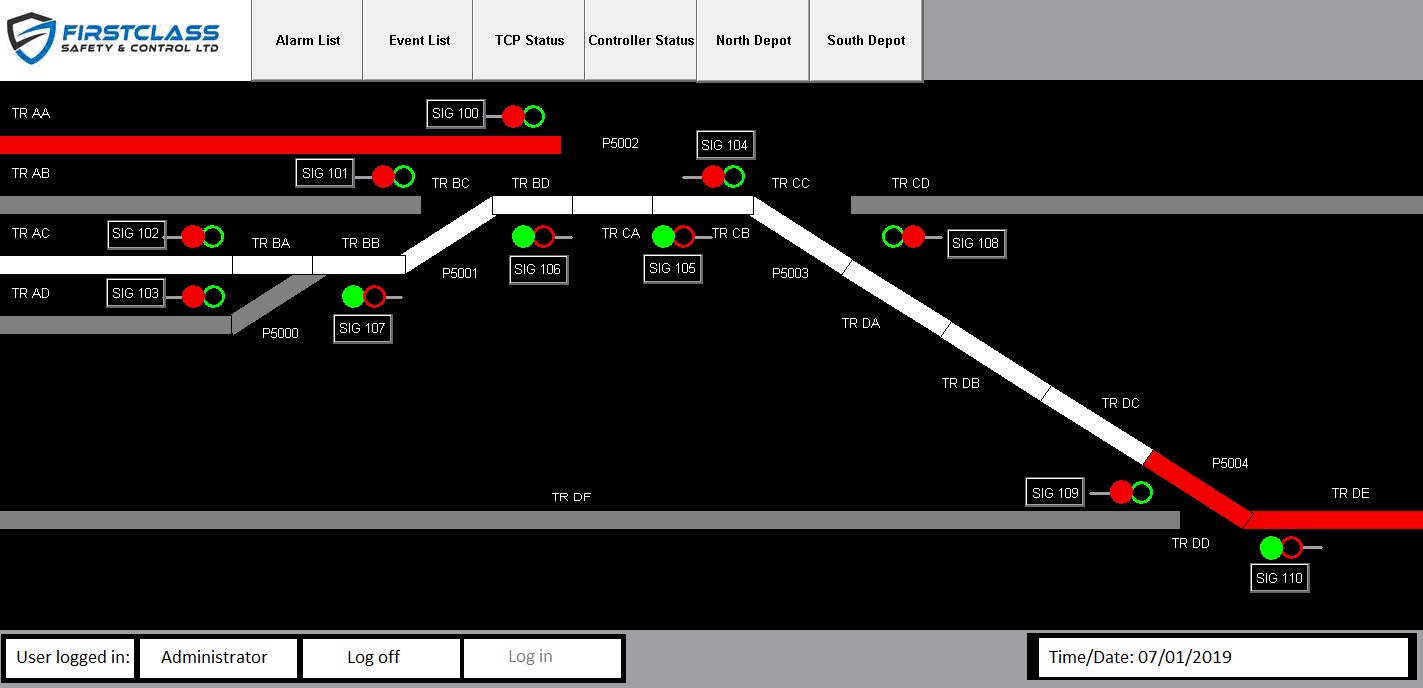

Depot Control System (DCS)/ Locally Operated Points System (LOPS)

FCSC have developed a SIL 2 rated DCS/LOPS system which is adaptable and reliable using proven technology. Our DCS / LOPS Systems are a bespoke design for each project yet will be the most cost-effective option available, whilst maintaining the highest level of safety and operability to meet the Depot’s needs.

Typical DCS Interface features:

- Depot Protection Systems

- Mainline Signalling NWR Interface

- Points Machines

- Aspect Signals

- Route Indicators

- Train Detection

- Track Circuits

- Industry Transponders

- Remote diagnostics

- Security & CCTV Systems

System, hardware features:

- Allen Bradley Control/Logix, CompactLogix and Flex I/O Remote Input Output: Reliable, high quality hardware.

- The Our SCADA uses a high-end Server for rapid response and actions

Software features:

- 100% configurable and COTS software, making integration and flexibility options endless

These innovative features mean our DCS/LOPS offer a range of benefits to our customers including:

- SIL rated safety reassurance

- Bespoke to meet with all our customer requirements

- Easily integrated into other systems

- Value for money

- Peace of mind

- Fully Validated with our chosen Signalling Specialists to latest Standards

Rail Depot Safety Training

To enhance our safety product portfolio our engineers, facilitate rail depot safety training courses for all our customers. These are highly rated by delegates both operationally and as part of ongoing maintenance requirements for depot staff.

Innovation and Product Development

At FCSC we recognise the need to continually evolve the current market safety and control product range to bring improvements and new concepts to our customers. Our advancements aim to bring increased efficiency and cost effectiveness to the rail industry. One of current developments is our combined DCS/DPS system which will offer a single solution for the whole depot with a single SIL 2 capable PLC Processor therefore eliminating unnecessary interface failure points but still maintaining the safety benefits of each System plus much more

To find out more about our flexible Bespoke DPS, DCS plus our additional services and products contact us at FirstClass on [email protected] Tel: +44 (0)1621 743743