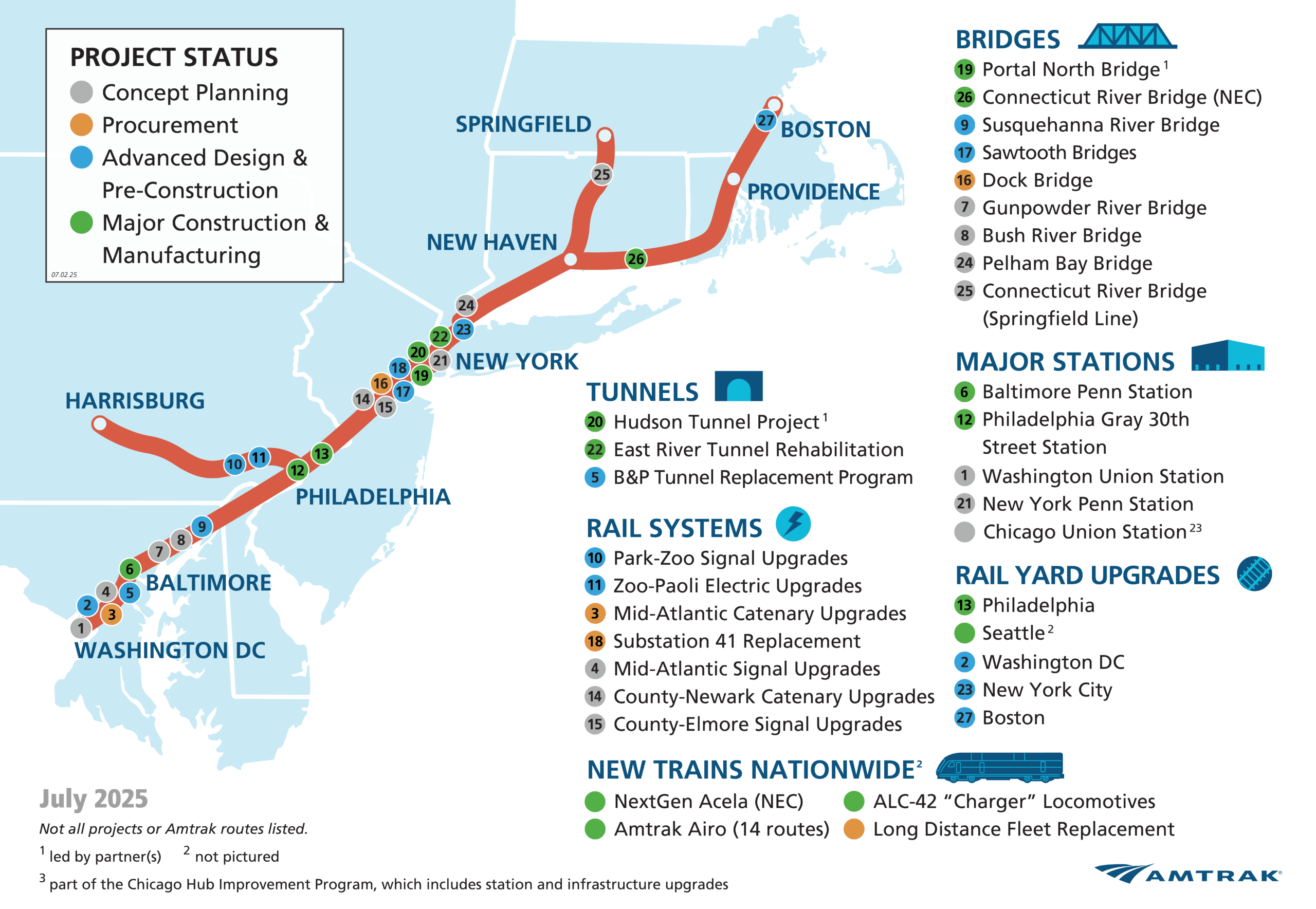

Welded Structures for Railway Application

AQ Welded Structures is focused on high quality metal processing services for Railway Welding including:

- Punch-laser processing

- Laser-cutting

- Punching

- Eccentric and hydraulic punching

- Bending

- High-speed machining

- Welding (manual and robot)

- Friction stir welding (FSW)

- Surface treatment

- Assembly

- Measuring & testing

Our modern plants in Estonia, Bulgaria, India and China offers excellent technology and highly motivated and skilled people. We are proud to be serving demanding industrial customers across Europe, North America and Asia. Our customer base besides railway industry is within commercial vehicles, general industry and telecom.

Our rapid growth is the result of dedication to fulfilling customer needs in respect of quality, service and cost.

Railway Welding

High quality welding is definitely one of our core competences. Our processes at different plants are certified according to well-recognized quality systems such as ISO 9001, ISO 3834-2, ISO 15085-2 CL1 and CL2.

Manual welding is done in aluminium, steel and stainless steel. We offer TIG as well as MIG/MAG welding services. Robot welding is done in aluminum, steel and stainless steel. Dedicated and skilled engineering teams gives us a great opportunity to provide design support to our customers.

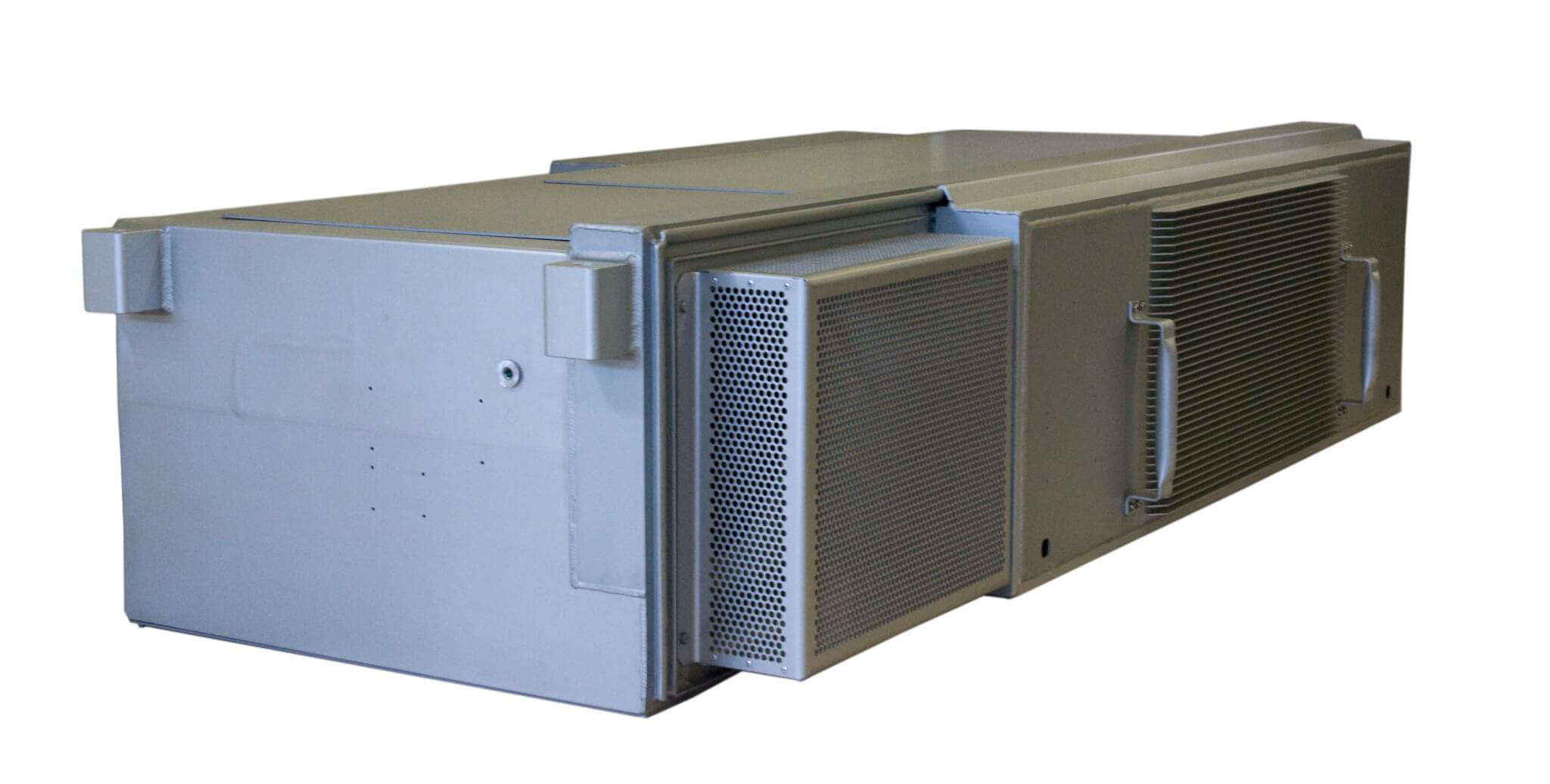

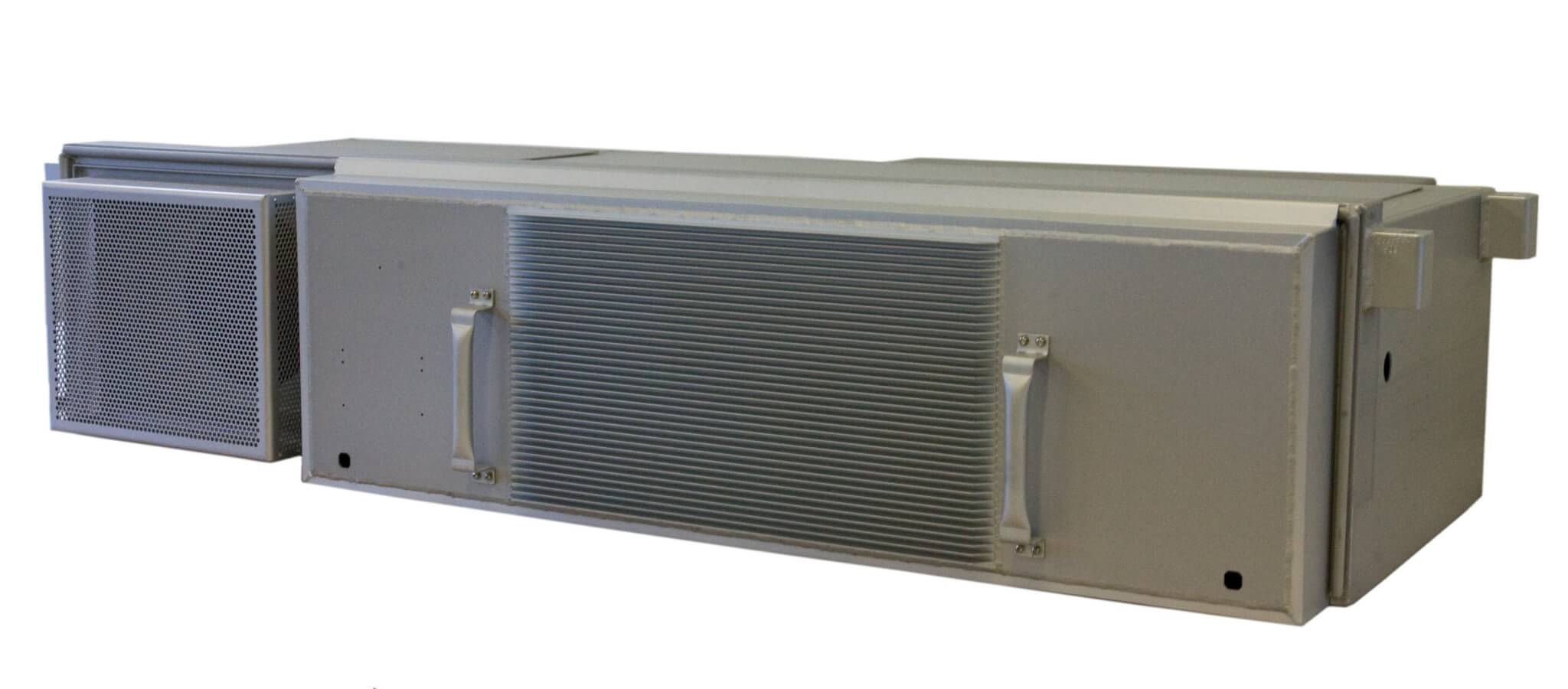

Product Introduction

Full PPAP process: product introduction process, prototype manufacturing, documentation, validation, testing, industrialising and quality assurance.

Friction Stir Welding

Our site in Estonia is one of few subcontractors in the area who have introduced stronger and cheaper method of aluminium welding – Friction Stir Welding. By this method a tool moves with whisking movements over the joint and “whisks” together the aluminium from the two parts that are to be joined together. By this means the joint is stronger than if it had been welded traditionally.

In such a traditional aluminium weld the strength is about 75% of the original material. Using FSW the strength goes up to about 95% in the area around the joint whereas the joint itself is stronger than the original material. The reason for this is that the zones creating an influence of heat never reach a temperature high enough to influence the crystalline structure of the original material. At the joint the structure is better than the primary material at the same time as the joint turns out extremely smooth and even.

Quality Certification

ISO/TS 16949

ISO 9001

ISO 15085-2 (CL1 and CL2)

ISO 3834-2

ISO 14001