Challenge: Preventing Vibrations in Next-Generation High-Speed Trains

The next generation of high-speed trains is facing a unique challenge: How can vibrations caused using locomotive drives be efficiently prevented? Unlike the decentralised single-vehicle drives used in high-speed trains of the past, modern high-speed trains are once again relying on stronger and larger locomotive drives.

This design inevitably leads to a greater unsuspended mass on the tracks. The result is significant vehicle vibrations due to track irregularities, especially at high speeds. These vibrations are directly transmitted to the gearbox, motor, and vehicle frame, which must be avoided.

How Is the Problem Manifested in Detail?

The problems caused by vibrations and shocks are manifold and have far-reaching consequences for the operation of high-speed trains. First, they lead to increased susceptibility to faults and wear, as well as material stress on the drive and vehicle. This shortens maintenance intervals and reduces the lifespan of critical components, significantly increasing long-term operating costs.

Vibrations and shocks also affect ride comfort. Passengers and railway staff perceive these vibrations as disturbing. The ride becomes noisier and less pleasant, affecting activities such as sleeping, reading, and overall comfort in the vehicle. For high-speed trains known for their smooth and comfortable rides, these negative side effects can impact passenger numbers and have long-term economic consequences. Moreover, the environment is affected. As speed increases, the train emits noise and transmits noticeable vibrations to the surroundings, such as when passing through stations or residential areas.

Solution: The Fully-Suspended Locomotive Drive Coupling ZBG 450 by Flender

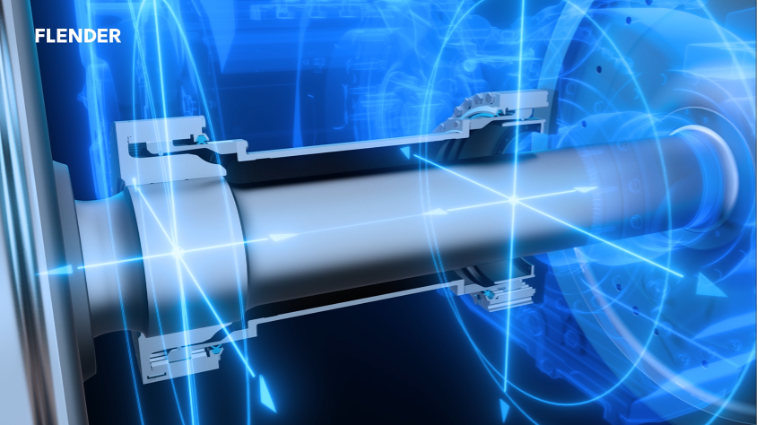

As the first coupling manufacturer, Flender has developed an innovative solution for this complex challenge: the fully-suspended locomotive drive coupling ZBG 450. This novel coupling is specifically designed to address the described problems and enhance the ride quality and comfort of high-speed trains.

The ZBG 450 coupling replaces the conventional double-cardanic, elastic couplings typically used in locomotive drives and features a unique concept. Unlike other couplings, it is a gear coupling that is significantly smaller than usual locomotive couplings because it no longer encircles the entire axle. While the axle still passes through the coupling, Flender has completely rethought the concept and reversed the interface to the coupling. The coupling is mounted on the side of the gearbox facing the axle connection. Conventional drives require a much larger and heavier coupling solution that must be guided through the gearbox’s hollow shaft. This design change reduces the weight by several hundred kilograms. Thus, it is a very cost-effective and lightweight coupling design that significantly improves drives for fully-suspended locomotives.

The ZBG 450 coupling was first presented to the public at InnoTrans 2024 and garnered great interest. It is a clear testament to Flender’s innovative strength and application and manufacturing expertise. With this solution, Flender offers its customers not only an effective way to tackle the vibration challenges of modern high-speed trains but also the assurance that they can rely on technologically advanced and reliable products.

Conclusion

Thanks to Flender’s fully-suspended locomotive drive coupling ZBG 450, major vibrations in next-generation high-speed trains are a thing of the past. This innovative solution allows the benefits of powerful locomotive drives to be used without the associated drawbacks of vibrations and shocks. The ZBG 450 coupling significantly reduces the susceptibility to faults and wear, as well as the material stress on the drive and vehicle, positively impacting the lifecycle of the drive. Simultaneously, it greatly enhances ride comfort, benefiting both passenger and crew satisfaction, and the environment by reducing vibrations and noise emissions.

Flender has successfully addressed a major challenge with the development of the ZBG 450. As the first provider on the market, Flender has developed a coupling solution that meets the specific requirements of modern high-speed trains while maintaining the highest standards of reliability and durability. The positive response from the market at InnoTrans 2024 underscores the company’s innovative strength. With the ZBG 450 coupling, Flender is setting new standards in the railway industry and offering a forward-looking solution that both reduces operating costs and extends the lifespan of vehicles. Flender’s customers can rely on this coupling technology to be well-equipped to successfully meet the challenges of modern long-distance travel.

This article first appeared in the Railway-News Magazine Issue 1 2025. Download the full PDF version here.