In a region where rugged terrain, remote environments, and limited infrastructure make traditional rail tracking a challenge, innovation is essential.

That’s why IntertechRail partnered with one of Brazil’s leading logistics providers to deliver a smarter, more sustainable way to monitor freight railcars in the São Luís corridor.

At the heart of the solution is a solar-powered, autonomous monitoring system powered by TransCore’s industry-leading RFID technology. This system provides real-time visibility into railcar movement, improves operational efficiency, and eliminates the need for manual tracking — even in areas with no external power.

The Challenge

The logistics network near São Luís plays a vital role in moving goods across Brazil. But without reliable power infrastructure or modern tracking tools, rail operators faced persistent challenges:

- Difficulty identifying railcars accurately and consistently

- Delays caused by manual reporting or data gaps

- Infrastructure limitations that made traditional installations costly or impractical

- Environmental goals that called for cleaner, more sustainable operations

- Accuracy in cost and stay tracking, based on the time each train composition remains in place

To address these issues, one of Brazil’s largest rail operators — currently the second-largest by network size and third-largest in Latin America — partnered with IntertechRail to design a resilient, low-maintenance system that would deliver dependable data under any condition — and do it without relying on grid power.

The Solution

IntertechRail’s monitoring system blends intelligent architecture with field-proven technology to deliver a fully self-sufficient solution. TransCore played a critical role in providing the RFID infrastructure and components that enable accurate, real-time tracking.

System Highlights

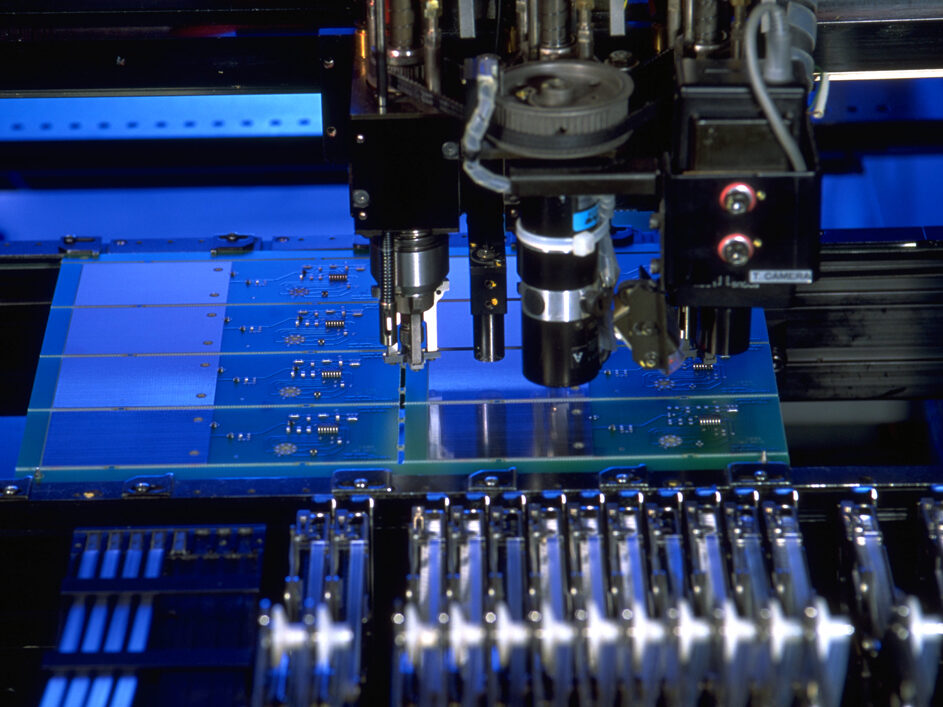

- Strategically Placed Monitoring Poles: The first pole features RFID antennas that scan railcars as they pass, while the second houses the MPRX RFID reader, an auxiliary antenna for redundancy, and a high-efficiency solar panel and battery system to power the entire setup.

- TransCore RFID Components: Durable tags installed on railcars pair with high-performance parapanel antennas and MPRX readers to ensure accurate reads, even at speed and in extreme conditions.

- Rail-ID Digital Axle Counting Sensors: Installed directly on the tracks, digital sensors detect axle movement and direction, helping identify railcars even without RFID tags — critical for building a complete Train Consist.

- Rail-ID Edge Connectivity: An embedded industrial modem processes all data onsite and transmits it to the cloud using an always-on connection. Customers access structured data through a secure API, enabling seamless integration with logistics platforms.

- Rail-ID AEI Server: Customers can access a fully automated tracking system via the web or local network, featuring a comprehensive rail map diagram with real-time car locations. Special reports are also easily accessible for enhanced monitoring and analysis.

The Result

This intelligent monitoring system provides a new standard for freight visibility and operational autonomy.

Customer Benefits

- Real-Time Data Access: Logistics managers receive immediate, structured updates on railcar movement, improving planning, responsiveness, and customer service.

- Autonomous Power: The solar-powered system operates independently from the electrical grid, minimizing installation and maintenance costs.

- Enhanced Accuracy: The combination of RFID and axle counting ensures that every railcar is tracked with a high degree of confidence, even in the event of tag loss or equipment redundancy.

- Sustainability: With no need for external power and minimal environmental impact, the system aligns with modern sustainability goals.

Looking Ahead

This project is more than a technological upgrade — it is a blueprint for smarter, more sustainable freight rail management. By pairing IntertechRail’s system design with TransCore’s trusted RFID technology, the team delivered a solution that not only solves today’s tracking challenges, but also prepares rail logistics for the future.

As rail networks continue to modernize across Brazil and beyond, this collaboration shows what’s possible when real-world challenges meet innovative thinking and proven technology.

This article was originally published by TransCore.