At InnoTrans 2024, Siemens Mobility is showcasing its new cloud-based Signaling X platform, alongside advanced features of Railigent X for next-level train maintenance.

Both advancements mark significant steps in the digitalisation of rail networks, enabling greater operational efficiency and flexibility while supporting the long-term sustainability goals of the industry.

Signaling X

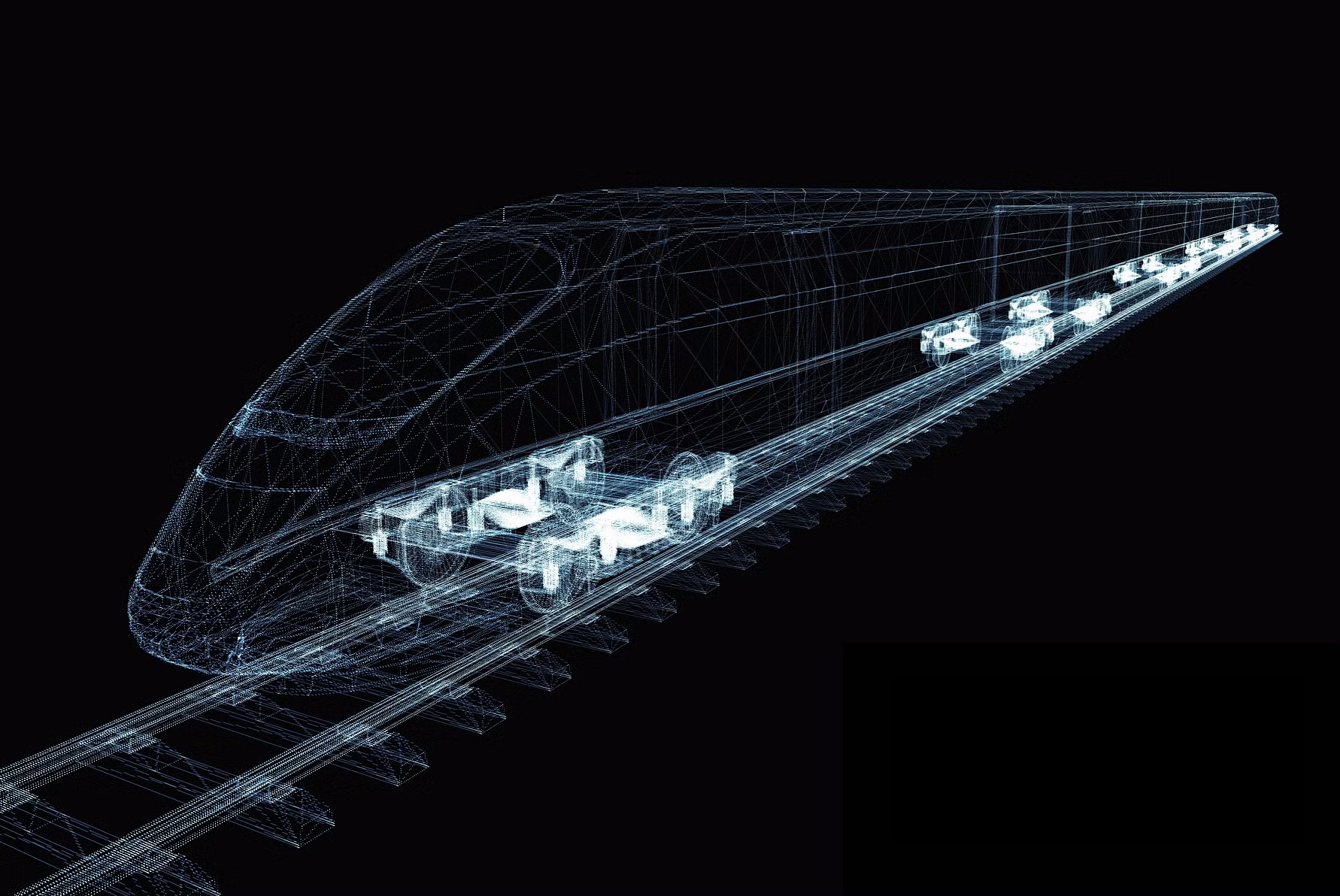

The newly introduced Signalling X platform integrates multiple signalling and control systems for mainline and mass transit networks into a single cloud-based solution.

This breakthrough enables seamless management from a single Signaling Data Center, which relies on standard hardware and open interfaces.

By leveraging standardised application programming interfaces (APIs), Signaling X allows rail operators to optimise rail operations and more effectively integrate diagnostic and optimisation systems, such as Train Planning Systems (TPS).

Michael Peter, CEO of Siemens Mobility said:Today, we are proud to launch our brand-new suite Signaling X to lead rail signalling and control systems into the digital future. Signaling X will be integrating different signalling systems into one cloud platform and opening their interfaces to further functionalities.

The platform utilises Siemens Mobility’s Distributed Smart Safe System (DS3), which ensures the safety-critical and non-safety-critical applications are run in a secure, cloud-based environment. DS3 delivers significant operational benefits, including up to 20% improvement in efficiency, 30% reduction in energy consumption, and shorter headways on rail networks.

Railigent X

Siemens Mobility is also introducing new features to Railigent X, its AI-driven platform for predictive and efficient train maintenance.

The platform’s latest advancements include fully automated visual inspections and mobile inspection capabilities, designed to optimise train service schedules and maintenance routines. By integrating AI models, Railigent X automates the detection of wear, anomalies, and other issues, allowing for faster and more accurate diagnostics.

With these new features, Railigent X offers flexibility in how operators use its services, either through fully integrated applications or selective use of its algorithms via APIs. This modular approach allows rail operators to tailor their digital strategies to their specific needs.

Fully Automated and Mobile Inspections

Siemens Mobility is further digitalising rail maintenance with its Fully Automated Visual Vehicle Inspection system.

This system uses AI-powered cameras to inspect vehicles as they enter depots, analysing up to 100% of the vehicle’s surface for technical issues or graffiti. This system will soon be demonstrated at the Rail Service Center in Dortmund, focusing on inspecting train roofs and equipment, further increasing the efficiency of depot operations.

In addition, Siemens is launching a Mobile Inspection service that enables rail vehicles to be inspected outside of depots. By using robotics and augmented reality, the Mobile Inspection solution allows for the examination of vehicle roofs and undercarriages directly on sidings, reducing the need for depot visits. This approach increases vehicle availability and optimises depot capacity.