Insulation Monitoring Devices for Traction Vehicles / Rolling Stock AC/DC IT System

HIG99 + HIG99 KM CAN

A traction container is a device that usually contains a galvanically isolated unit of a multi-quadrant power converter, which serves to regulate the traction motors of electric traction vehicles. Usually the traction container contains one converter, which drives one to two traction motors.

Due to increased safety and reduction of EMC/EMI influences, each traction container is designed as an isolated system, galvanically separated from the vehicle body as well as from the input voltage. From the design point of view, an isolated HF system is created by an isolating transformer, followed by part of the rectification by a multi-quadrant rectifier, which creates a direct current intermediate circuit, and the inverter itself, which supplies the required value of alternating voltage and variable frequencies for the traction asynchronous/synchronous motor. The isolated system of the drive unit is therefore in most cases a combined AC/DC isolated system. That is, a system that contains a galvanically connected alternating and direct current part and insulation fault may occur on both systems.

In these cases, AC/DC type insulation monitoring devices are used to monitor the insulation. These devices are able to detect insulation breakthroughs both on the AC side (i.e., motor side) and on the DC side (i.e., inverter intermediate circuit side).

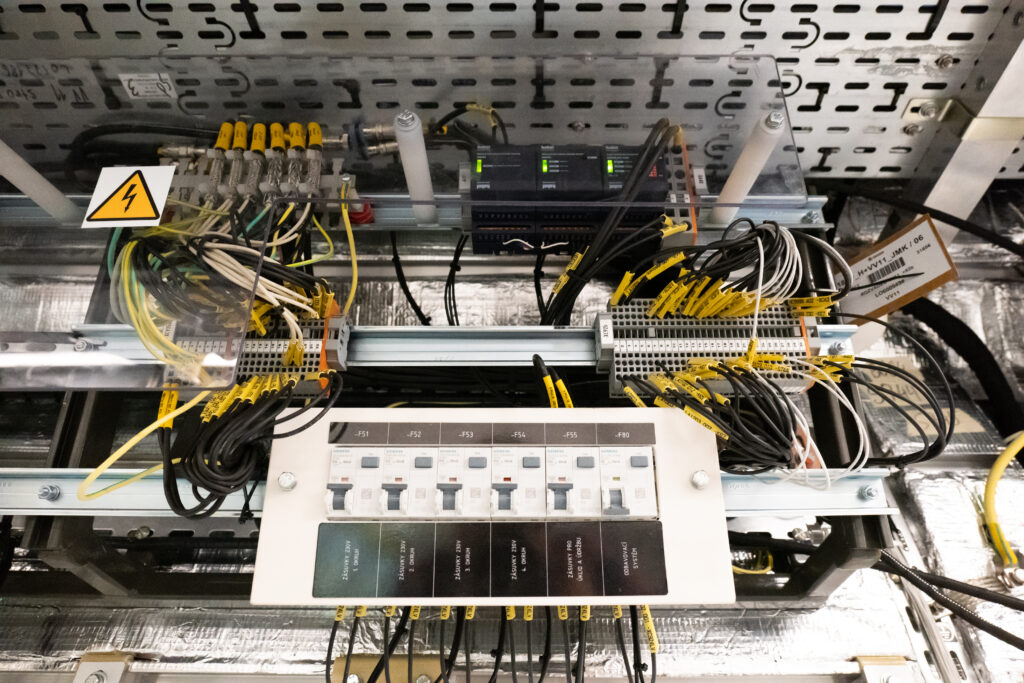

HAKEL uses the HIG99 insulation monitoring device for these purposes. These are insulation monitoring devices that meet the requirements of EN 50155 and IEC 61557-8 standards. The measured range of insulation resistance of this device is 1 kΩ to 10 MΩ and the device is supplied with 24 V DC independent low voltage. From the point of view of the measured system, the permissible voltage is 1000 V DC / 710 V AC (10 to 440 Hz). If it is necessary to monitor the higher network voltage, it is necessary to use a HIG-CD 1k8 coupler, which allows up to twice the voltage of the measured system. The HIG99 device can inform the user about the insulation status via relay or the HIG99 KM CAN communication module can be used for direct connection to the CAN bus bar with the CAN OPEN protocol.

In terms of location, we recommend selecting the place where the insulation status fault is most likely to occur as the connection point of the insulation monitoring device. In the case of the traction container, it is the AC side, because the most common cause of insulation fault in the drive unit is usually the traction motor insulation disruption. For more information please visit our website.

IMD types HIG99 + HIG99 KM CAN were recently used or will be used by ŠKODA TRANSPORTATION in the following projects:

- Czech Railways: 5 sets for two-storey push-pull train sets

- Czech Railways: 79 sets for low floor trains

- Poland, Warsaw: 45 sets for six-car metro trains

This article was originally published by HAKEL.