The SB rail fastening system has been a cornerstone of the railway infrastructure in Poland for decades, with the SBW3 variant widely recognized for its reliability and durability.

The SBW3 system, manufactured by voestalpine Fastening Systems Sp. z o.o., has long been known for fastening rails to prestressed concrete sleepers. Building on years of experience and innovation, voestalpine Fastening Systems has now launched the SBW4 rail fastening system—a groundbreaking development that addresses installation challenges and improves system performance.

From SBW3 to SBW4: Addressing the Key Challenges

Despite its success, the SBW3 system reached its limits in terms of assembly ergonomics and adaptability to modern automated processes. Our engineers recognized these challenges and launched a comprehensive research and development initiative in 2019. With support from the Wielkopolska Regional Operational Program, the team aimed to improve the SBW3 system with the following key areas:

- Improved ergonomics during assembly.

- Improvement of electrical resistance.

- Reduction of material weight with economic and ecological advantages.

- Suitability of the system for automatic assembly.

The Most Important Innovations of the SBW4 System

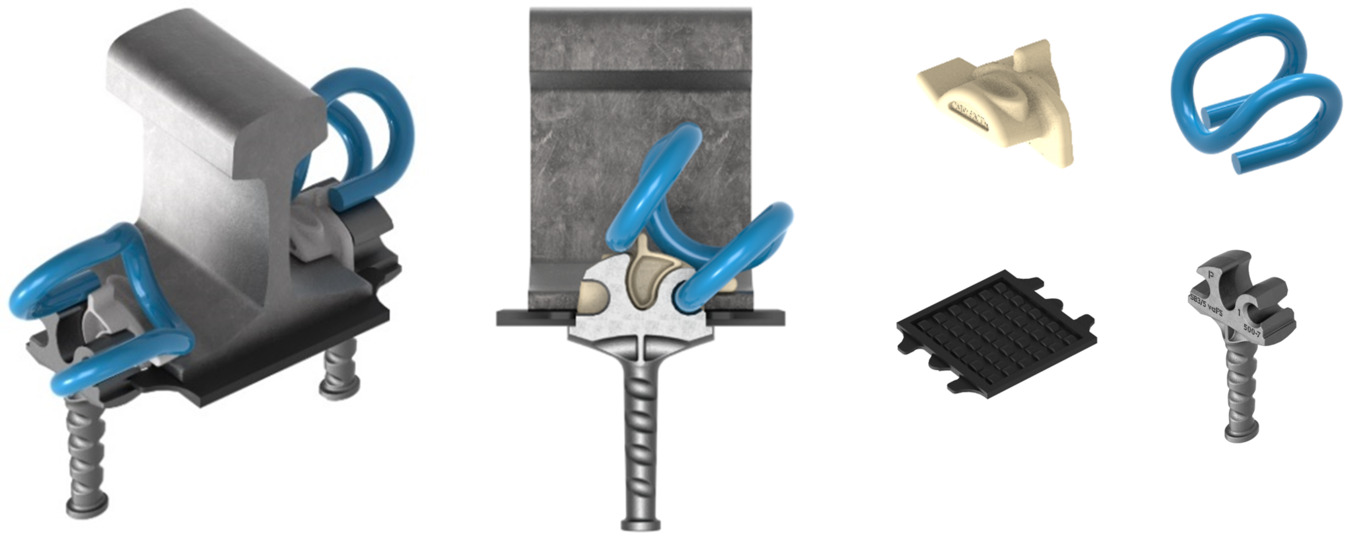

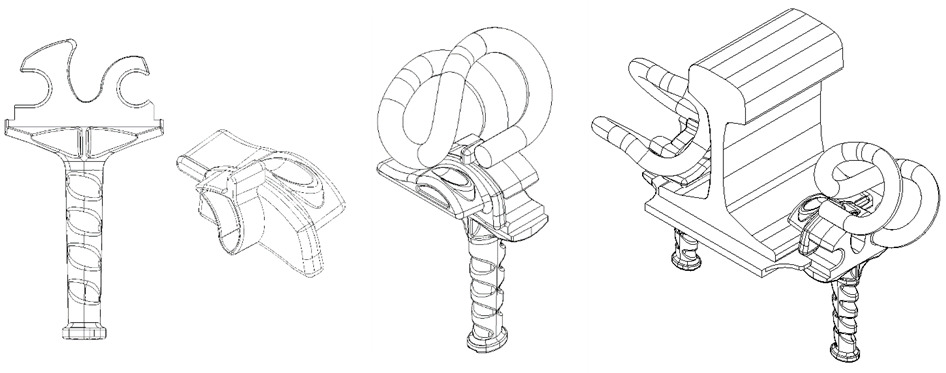

- Improved Ergonomics: The modified SB3/5 cast iron anchor and the WIW60C electrically insulating clamp standardize the positioning of the SB4 spring clamp. A specially designed lug ensures secure and repeatable positioning and simplifies manual installation. Furthermore, a redesigned anchor head reduces the force required to tighten the clamp, making the process more efficient.

- Improved Electrical Resistance: The PWE6094R rail pad features redesigned lateral ribs that reduce water retention and improve electrical resistance, consistently exceeding 10 kΩ during testing. This improvement ensures greater safety margins and compliance with EN 13481-2 standards.

- Reduced Weight for Greater Sustainability: The hollow design of the SB3/5 anchor head reduces weight by 20%, thus lowering production and transportation costs. This change not only improves economic competitiveness but also reduces the system’s environmental impact.

- Automation-Ready Design: The SBW4 system integrates seamlessly into automated assembly lines, reducing manual errors and increasing rail assembly efficiency. Tests have confirmed that the clamping fixtures available on the Polish market are capable of effectively positioning and securing the SBW4 clamps, making the system future-proof.

Proven Performance and Compliance

The SBW4 system has undergone rigorous testing, including type tests and qualification procedures at the Railway Institute in Warsaw, and meets the stringent requirements of EN 13481-2. Each component of the system is patented, reflecting our commitment to innovation and quality.

Advantages for Rail Construction and Maintenance

The SBW4 system streamlines the installation process, enabling faster and more consistent track laying. Improved electrical resistance and a lower carbon footprint also contribute to the system’s appeal. These innovations ensure that the system meets modern requirements while offering a competitive price.

Leading Edge in Rail Infrastructure

With the SBW4 rail fastening system, we demonstrate our leadership in rail infrastructure solutions. For more information about the SBW4 system and other innovations, please follow the link to the fastening page.

This article was originally published by voestalpine Railway Systems.