Reliable and durable fastening is every manufacturer’s dream.

From manufacturing to transport, from electronics to architecture, there are countless applications where fasteners ensure the proper functioning and safety of a device or structure.

However, safety can sometimes be compromised by problems such as loosening, i.e. the reduction in the tightening force that connects two elements of a fastener. Such loosening can cause leakage, breakage, damage, and incidents of varying severity. For example, a survey on automobile dealer service managers in the United States indicated that 23% of the service problems were attributed to the loosening of threaded fasteners. The transport sector, specifically rail, marine, aviation, and aerospace, is critical in this respect.

Possible Causes of Fastener Loosening

There can be several causes of fastener loosening after assembly, ranging from a human error to environmental conditions. Loosening often occurs when fasteners are subjected to vibration, shock, or thermal expansion.

Some of the factors to consider are:

- Vibrations. They can cause small transverse movements acting against the friction between two elements of a fastening system, leading to a loss of clamping force.

- Differential thermal expansion. Different materials may respond differently to variations and changes in temperature, causing the assembled parts to expand or contract, with possible loosening of the fasteners.

- Shocks. Dynamic or alternating loads from machinery, equipment, etc. may cause mechanical shocks resulting in slippage and/or loosening of the fasteners.

- Weak tightening. For safe assembly, you must always keep in mind the tightening torque, namely the force required to tighten a nut, screw, etc. Each element should be tightened according to a specific tightening torque: if you tighten too little, you risk loosening; in the opposite case, you risk deformation or breakage. Usually, the required tightening torque is indicated along with other values in the manufacturers’ catalogs and data sheets.

Anti-loosening Fasteners by Specialinsert®

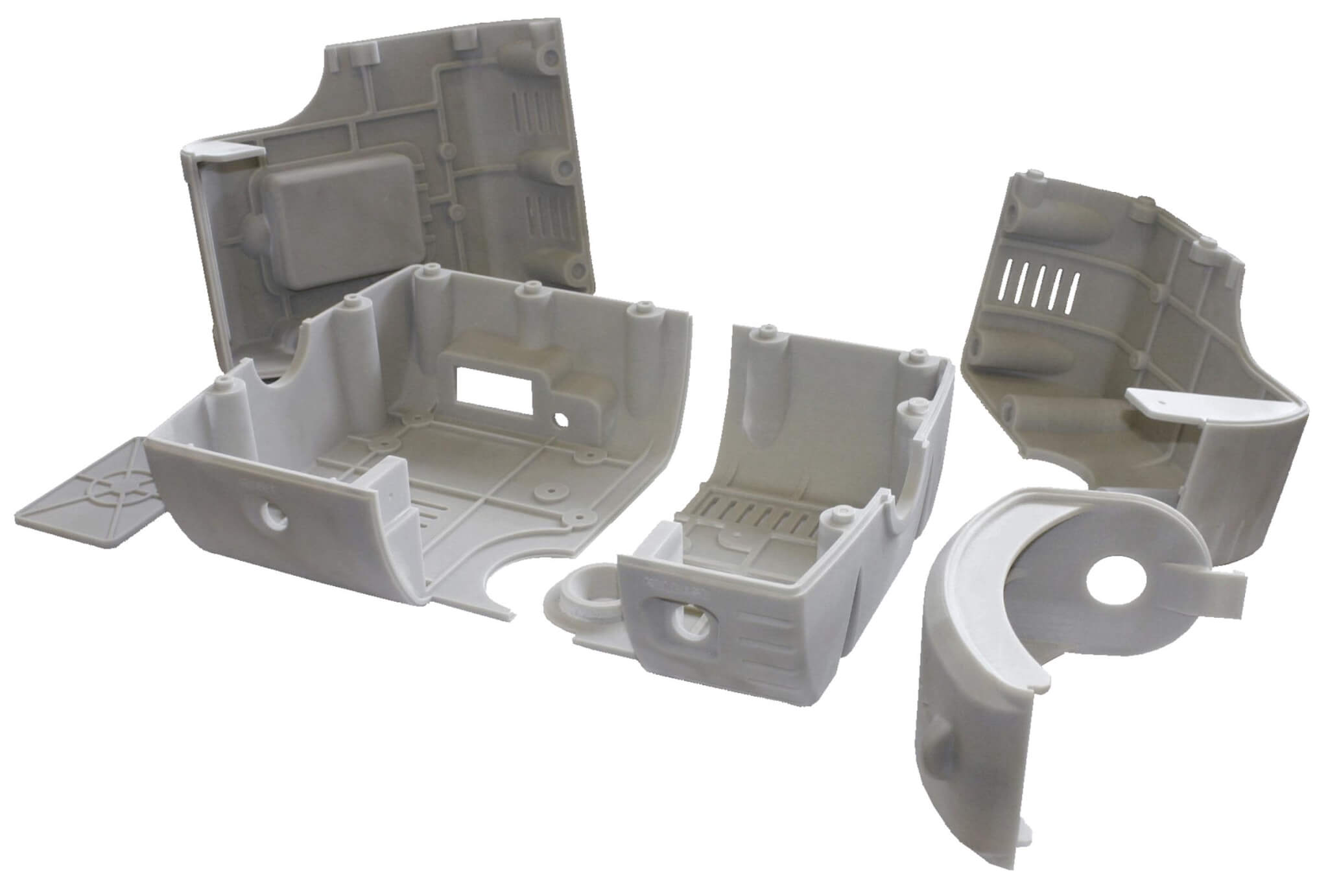

One of the most innovative solutions patented by Specialinsert® for parts subject to loosening and strong vibrations is the self-locking DEFORM-NUT®. It is a deformable threaded tubular rivet with a self-locking thread, available in cylindrical or hexagonal versions, which provides a nylon ring at the end of the thread to rub the screw during assembly.

This product combines the advantages of classic deformable threaded rivets with those of self-locking nuts, guaranteeing the installation on parts with no access to the inside, anti-unscrewing properties without the need of additional components, and quick assembly of the connecting screw. The self-locking DEFORM-NUT® is also available in galvanized steel and stainless steel, in different shapes. Watch the video installation to find out how it works.

Another fastener, ideal for solving fastening problems on parts subject to vibrations, is our RUBBER-NUT, an anti-vibration insert in vulcanized rubber with a threaded brass bush inside.

Specialinsert® also provides its customers with two test laboratories for the development of new prototypes and checking existing products, which can perform pull-out, compression, hardness, and torque tests. To submit a request or a project, please contact our technical support.

Developing increasingly reliable and durable fasteners is one of our goals. To achieve this, we rely on our expertise, which is the result of an established tradition and ongoing communication with customers and partners. Together we contribute to the innovation of fasteners.

This article was originally published by Specialinsert srl.