Today, railways are only just beginning to tap into the full potential of GIS, writes Erik Henderson, Esri Solutions’ Director Rail Industry Solutions.

Railways operate across large, complex environments, where tracking assets, improving safety and enhancing efficiency are all crucial.

Historically, geographic information systems (GIS) have been used to support mapping of their extensive infrastructure, however they can offer so much more. GIS technology tends beyond mapping – it encompasses spatial analytics, predictive maintenance, data-driven decision-making and much more.

It’s likely you’ve been collecting huge amounts of data from your trains, switches and localised sensors – data that can be used in many more ways to optimise your operations. Here are five examples of the ways GIS can be used to further optimise rail safety and efficiency, as well as maximise value.

1. Managing and Monitoring Real Estate Assets

Railways own extensive land assets so keeping track of parcels (a piece or unit of land), property boundaries and taxes can be a real challenge. Here are a few examples of the way GIS could be used to help with this.

Property Accounting

Railways naturally have large geographic areas, which leads to challenges in maintaining constant access and maintenance of properties. Furthermore, determining properties’ land usage, proximity to environmental hazards and existing conditions can be difficult.

GIS provides significant value here by enabling public and private datasets to be overlaid on railway networks, offering critical insights where needed.

Taxing District Overlays

In the United States, taxing districts often vary widely among cities, towns and provinces, and they can change independently of each other. This creates a challenge for US railways to keep up with where they’re being taxed, and by who. As these tax districts are becoming more freely available digitally, rail parcels can be easily overlaid and tracked for changes.

Parcel Transactions

Going deeper than routine parcel transactions, GIS can be used to help railways determine the most suitable areas for network expansion or rationalisation. This is because there are many vendors that are compiling nationwide parcel coverages that allow railways to overlay parcels to look for detailed information on abutters – owners of adjacent land.

Key Site/Industrial Development

How can you help potential customers to choose freight rail over road? Companies can benefit from more cost-effective shipping of raw materials and products when they can locate along rail networks, so this makes it critical for railways to be able to identify large parcels suitable for industrial development – as well as identify those companies looking to relocate who require sites with the right criteria.

In this scenario, GIS is yet again an enabler, helping railways to identify industrial development opportunities and optimise land use.

2. Optimising Assets with Spatial Analysis

Rail networks require constant monitoring and maintenance to prevent failures, and GIS can support this. Asset tracking, using machine learning (ML), can detect infrastructure changes for example, while predictive analytics can be used to predict track wear based on factors like weather and tonnage.

Asset Change Detection

Many railways are deploying cameras across their networks to visualise conditions and assets as their trains roll through. New ML algorithms are being trained to recognise railway assets, allowing their automated comparison from run to run, highlighting any changes on a network.

Rail Break Predictive Analytics

The power of big data analytics can take years off track inspections, whether they’re manual or automated, and look for patterns over time. Those patterns can then be applied looking forward with the addition of variables like tonnage, rail weight, weather conditions and maintenance to predict where excessive deterioration may occur in the future.

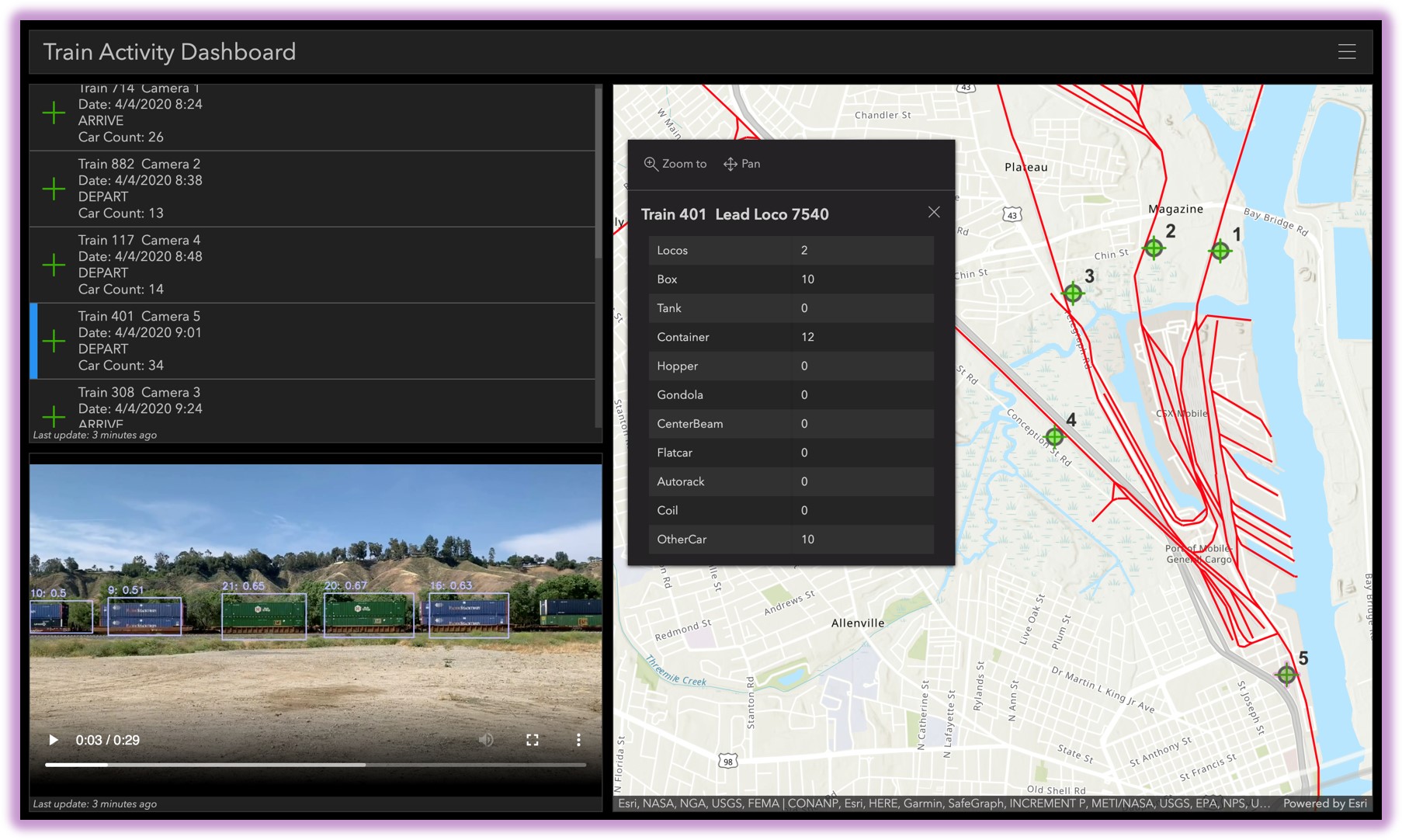

Historical Tracking

Train movements can be modelled by looking at both the car movements through stations, consists moves and maintenance logs. These can be combined with GPS logs from locomotives to identify where trains are being run optimally as well as those that are causing bottlenecking. Overlay these on customer site layouts and determinations can be made as to best practices for ordering cars and serving customers.

3. Enhancing Emergency Management and Safety

Accidents and emergencies require instant access to asset data for faster response times. GIS can help by providing real-time access to asset data through mobile apps, while crowdsourced reporting allows the public to flag track obstructions and post-storm damage.

Real-Time Access to Historical Asset Data

Regardless of the size and scope of the emergency, remote access to information is always important. Digitally storing critical asset information is key, but there is a key advantage to linking it spatially to each asset. This allows it to be easily recalled through an app on a mobile phone that knows your exact location, which can be a matter of life or death in time-sensitive situations involving train movements.

Emergency Damage Assessment

Emergencies can happen at any time, anywhere. This often causes personnel to react on the fly and determine areas and assets that need assessment. The power of mobile collection tools is in their flexibility to adapt and be spun up. Esri Solutions harnesses pre-built templates for assessments that can be deployed to virtually any mobile device, using voice recorders and cameras.

Crowdsourcing Collection/Notifications

In the same fashion as employee assessment tools, public facing tools can be just as beneficial. Many districts deploy citizen crowdsourcing tools to allow for reporting of conditions that are important to the railways.

Track obstructions, weather conditions, post-storm reports, etc can all be sent in and analysed for priority of employee responses.

4. Leveraging Imagery and LiDAR for inspections

Traditional inspections can be time-consuming and hazardous, however drones and LiDAR scans can provide high-resolution 3D mapping of rail infrastructure can reduce risks and time taken, while automated rolling stock inspections can quickly identify issues before failure occurs.

Locomotive Front-End Cameras

Most often used for public crossing and pedestrian strike litigation, more recently locomotive front-end cameras have been used to feed ML models, looking for railway assets. These models can be trained to look for many kinds of anomalies that often can’t be routinely detected by human visual inspections.

Road Crossing Monitoring

Road crossing blockages often lead to public complaints and can cause safety issues when emergency personnel are blocked. Video monitoring of crossings can be used to determine where trains are blocking crossings in real-time. These alerts can then feed to routing engines which can alert those emergency personnel to more suitable routes to take.

Entrance/Exit Rolling Stock Inspections

More advanced inspection stations are being deployed on networks around the world. The imagery taken of these cars and engines can be used to identify mechanical issues that can lead to failures, as well as those that could lead to catastrophic derailments.

Aerial Drone Imagery

Railway yards and right of ways are extremely dangerous areas and not conducive to frequent ‘boots on the ground’ inspections. Drones have proven to be a vital tool for inspecting these areas, where engines and cars are constantly moving.

Going beyond simple imagery, geo-referencing aerial images can prove vital in the tracking of condition changes both in the tracks, as well as the environmental conditions around them that can cause change.

Inspection Car Rail and Sleeper Imagery

Another developing use case for ML in imagery is of the high-resolution images being collected of the rails themselves, along with the ties/sleepers.

Geometry cars are being outfitted with more and more sensors to conduct inspections of the rail infrastructure and those images are being analysed for change. The exception reports being generated can then be assigned to the precise geographic locations and fed into artificial intelligence (AI) models looking for patterns.

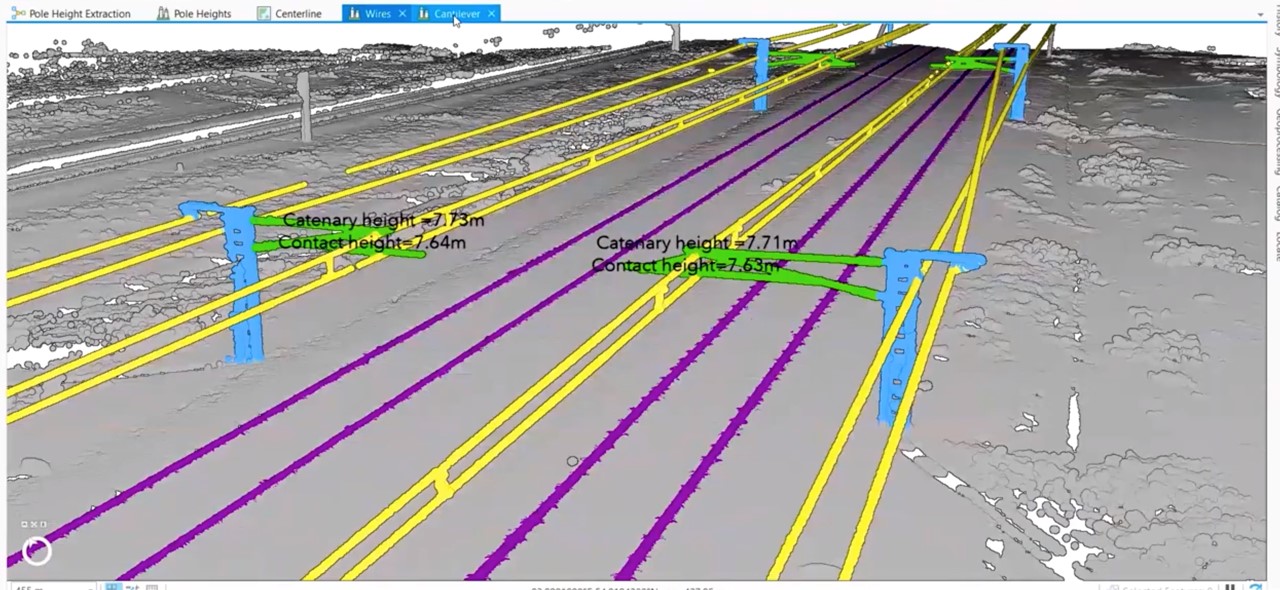

LiDAR

The advent of LiDAR remote sensing technology has changed the 3D model game and now that hardware is becoming more readily affordable, we’re seeing it deployed with greater frequency.

A challenge facing railways is what to do with the massive amounts of data these units collect. Deploying the right tools to analyse the information and identify assets looking for changes and anomalies can maximise the return on investment (ROI).

5. Improving Project and Maintenance Management

Maintenance projects cause disruptions, therefore efficient scheduling is crucial. GIS can be used to help improve resource allocation and that track work and train schedules are properly coordinated, as the examples below show.

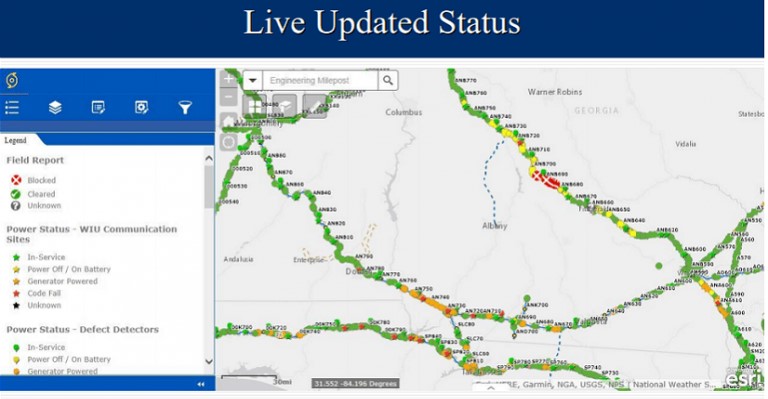

Real-Time Equipment Monitoring

Maintenance equipment on-track must be monitored, whether it is railway owned or owned and operated by consultants and vendors. An advantage those contractors can provide to the railway is the real-time tracking of their equipment. This can be done for all trains, engines, equipment, hi-rail vehicles and even employees.

GIS provides the platform to merge all of these in one location, allowing operations personnel to know exactly where train movements have the potential to be impacted at any time throughout maintenance windows.

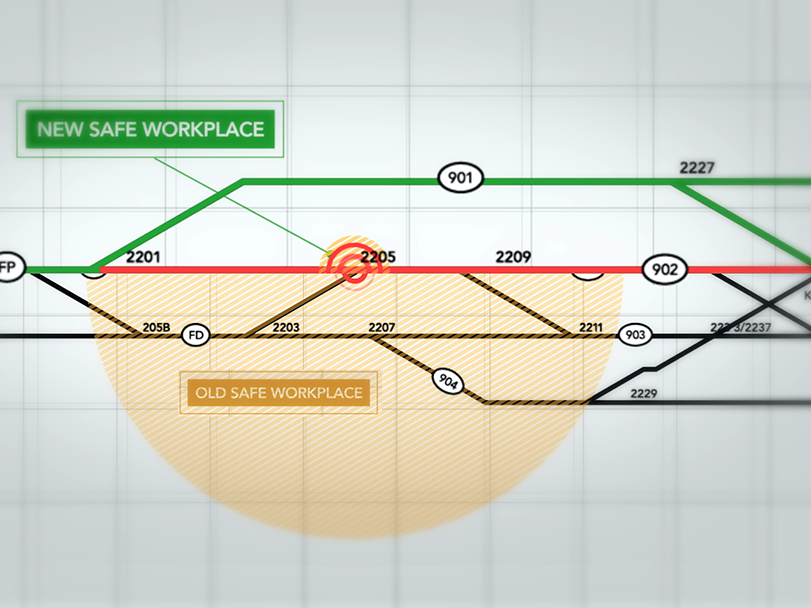

Multi-Staged Monitoring

Railway projects are inherently complex, often requiring track work that leads to train stoppages. Tracking these projects throughout their various stages is ideal for a GIS where field workers can provide live updates that can relay track statuses to oversight personnel.

While a construction project could last anywhere from hours to weeks or months, the stages of the process can all be tracked through updates to each individual track segment. Those segments can be monitored in an executive dashboard allowing for more informed daily decisions on routing.

Track Time Scheduling

The nature of railways asset maintenance lends to multiple departments having oversight of assets in the same geographic area. In the same way a roadway has one team who oversees asphalt and the paint stripes on the surface, another team is responsible for the water main running beneath it.

Railway maintenance can be tracked and monitored to identify when work is to be scheduled months in advance so that multiple teams can take advantage of maintenance outages and minimise track outages.

The Expanding Role of GIS in the Rail Industry

As you can see, GIS is revolutionising rail operations far beyond simple mapping, and we’re only just scratching the surface of what’s possible. As technologies advance, expect to be able to use GIS across an even wider range of use cases.

To stay informed of the latest GIS advancements for rail, join our mailing list here: GIS for Rail | Location Analytics Solution for Railways.

If you would like to be contacted with more information, contact us at [email protected].