Hitachi Rail has partnered with ROBOZE to improve the production of railway spare parts.

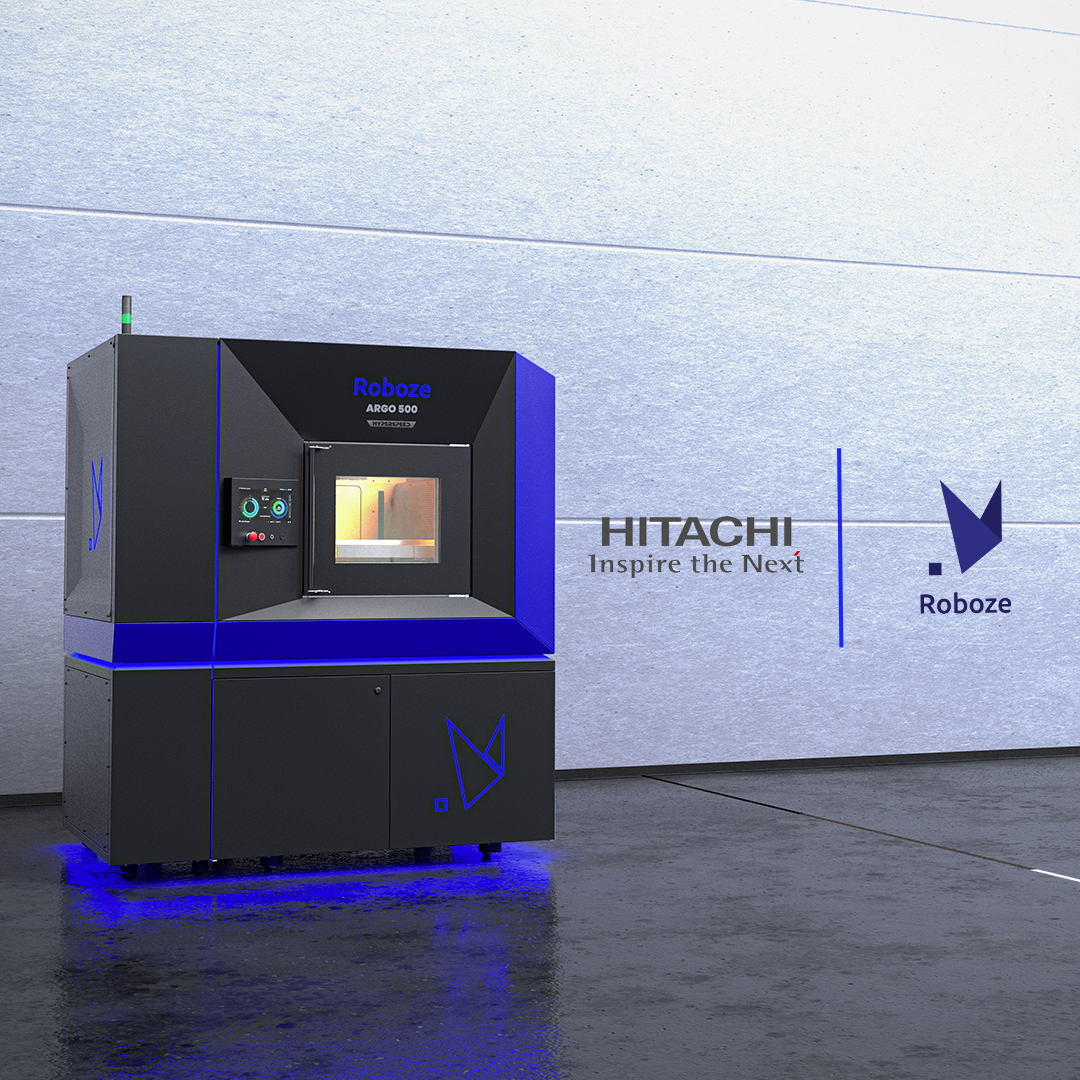

This partnership will use the ROBOZE ARGO 500 3D printing technology to enhance efficiency and reduce costs and delivery times for railway parts.

ROBOZE’s ARGO 500 technology will be used at Hitachi Rail’s facilities in Naples, Italy, as well as its new digital rail factory in Washington County, Maryland.

The new rail car factory in Maryland is a significant investment for Hitachi Rail, with a budget of 70 million USD. This facility will deliver the new fleet of 8000-series railcars for the Washington Metropolitan Area Transit Authority (WMATA). By using ROBOZE’s 3D printing solutions, Hitachi Rail aims to produce prototypes and spare parts more efficiently for this project.

The 3D printing solution aims to address the challenges of spare part availability and production costs in the railway industry.

Traditional machining methods for metal parts can be time-consuming and expensive. With the ROBOZE ARGO 500, Hitachi Rail will produce parts more quickly and cost-effectively. This approach will help reduce expenses and delivery times, streamlining the supply chain.

The partnership also includes engineering services and expert consulting from ROBOZE, providing ongoing support and specialised knowledge from teams in both the United States and Italy.

Luca D’Aquila, COO Hitachi Rail Group and CEO Hitachi Rail Italy said:Our partnership with ROBOZE underlines our commitment to delivering advanced, high-quality manufacturing for our customers. The partnership will enable us to harness 3D printing to improve operational efficiency and reduce costs for producing prototypes and railway spare parts. This additive solution will be used at our Naples site in Italy and our new digital factory in Washington County, Maryland. allowing us to respond effectively to our customers' needs.