UK Rail Depot safety control specialist FirstClass Safety & Control Ltd (FCSC) have recently completed two projects for KiwiRail in New Zealand, in collaboration with our rail partner Freightquip Pty.

The UK-based rail safety specialist was commissioned to design, manufacture and install their flagship Depot Protection System (DPS) at the Waltham Mechanical Hub (Depot) located in Christchurch, NZ.

Waltham will become the main South Island locomotive, passenger carriage and wagon maintenance facility for KiwiRail. With 47 new low-emission Stadler locomotives due to join the South Island fleet from 2024, this purpose-built mechanical hub will support the future resilience and efficiency of KiwiRail’s operations.

The FCSC SIL-2 DPS at Waltham Mechanical Hub comprises of:

- 9 Road Double Ended Hub

- Interlocks with Critical Key Lockout Boxes / Wheel Lathe / Drop Table / Depot Doors

- Bespoke Sounders to audibly present both Tone & Voice

- Full SCADA system for feedback of live DPS operations

- Internal Shunting & Permissive Movement’s (Through Road)

- Protection to Infrastructure & the people of KiwiRail

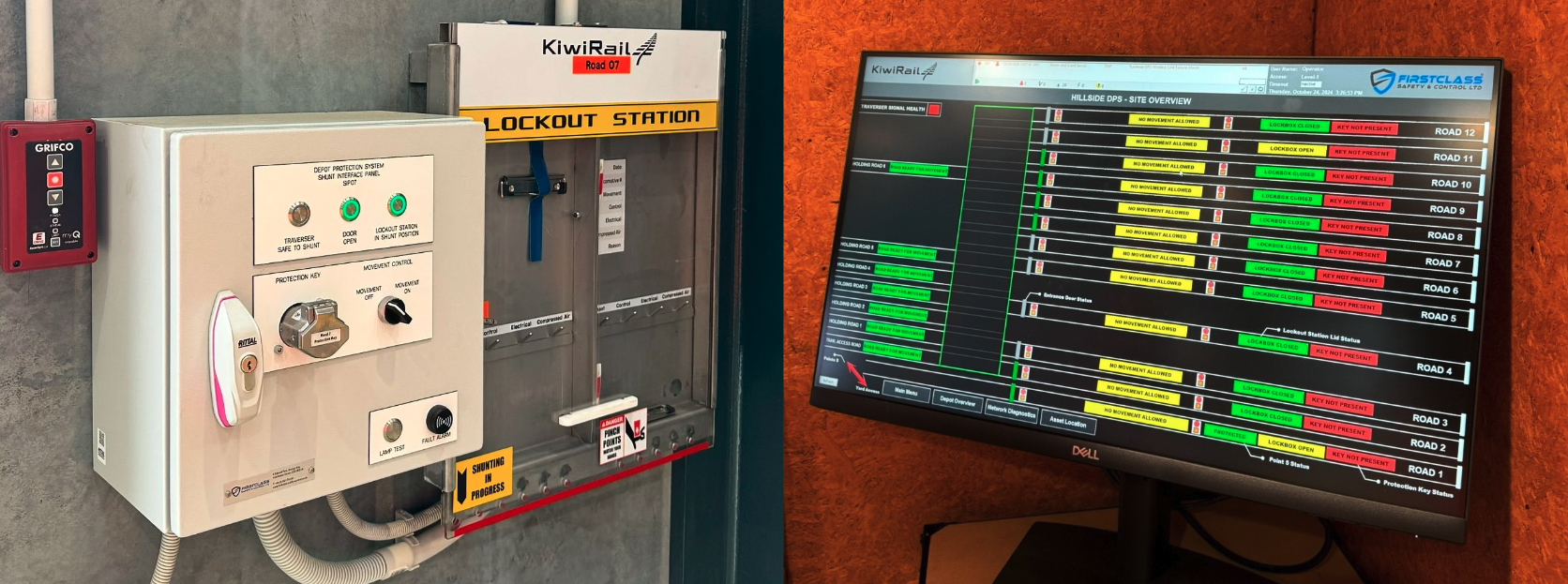

The 2nd project has been installed at Hillside Mechanical Hub, a historical site for the manufacture of Wagons & Heavy Assembly, which now has a bespoke solution to control safe vehicle movements across the site.

A user-centric system has been provided, bringing KiwiRail’s facility into the new age of safety in Rail Depots, mixing a mechanical interlocking system with a wireless interface to the 11 Road Traverser on site.

This FirstClass Safety DPS comprises:

- 12 Mechanical Building Roads / 7 Holding Roads

- Interlocks with Mechanical Points (Turnouts), Critical Key Lockout Boxes / Depot Doors

- Bespoke Sounders to audibly present both Tone & Voice

- Full SCADA system for feedback of live DPS operations

- Zonal Movement Permissive

Mark Meyrick, Director of FirstClass, said:We are delighted to be enhancing rail depot safety across the globe, in collaboration with partners such as Freightquip and Traction Group. Our innovative approach to system design and architecture not only makes it easier to support and manage international installation, but is future proofed to allow for modifications and upgrades, offering flexible and guaranteed protection for assets and staff for decades to come.

This article was originally published by FirstClass Safety & Control.