Expanding Aluminium Honeycomb Core

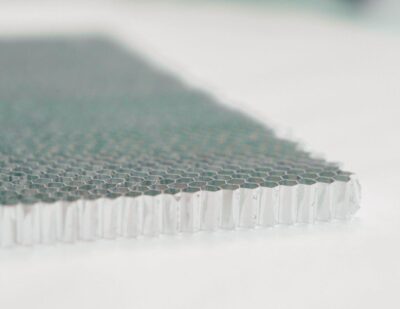

Corex Honeycomb is the only UK manufacturer of aluminium honeycomb. The material is supplied in both expanded and unexpanded formats for a range of industries including rail, marine, automotive, architecture and building.

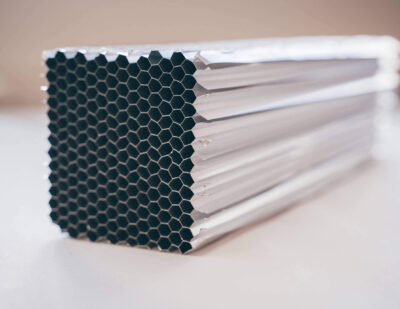

The aluminium honeycomb manufacturing process starts with a roll of aluminium foil which is printed with adhesive glue lines, cut to size, stacked and pressed to form a block of honeycomb. These blocks can then be cut into slices, which then need to be expanded to complete the process. At our factory in Cambridgeshire two methods of aluminium honeycomb expansion are used: manual and machine.

The process of expansion is dependent on the type and size of honeycomb and also the quantity that is needed.

Unexpanded honeycomb is easier and more cost effective to transport but then needs to be expanded before use. It is worth noting that when expanding honeycomb, the width of the honeycomb slice is reduced by approximately one third, so movable pins are crucial to ensure it is stretched evenly and correctly.

There are two main methods of expansion:

- Manual expansion

Thin slices of aluminium honeycomb, or honeycomb with a large cell size (1” and ¾”), in lower quantities can normally be expanded manually “by hand”, as sophisticated equipment is not required to complete the process.

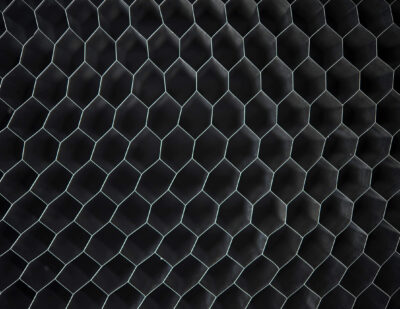

The image below shows one method of hand expansion where two people, wearing cut-resistant gloves, grip opposite ends of the unexpanded core. The core is expanded by pulling it until the honeycomb reaches an even hexagonal shape.

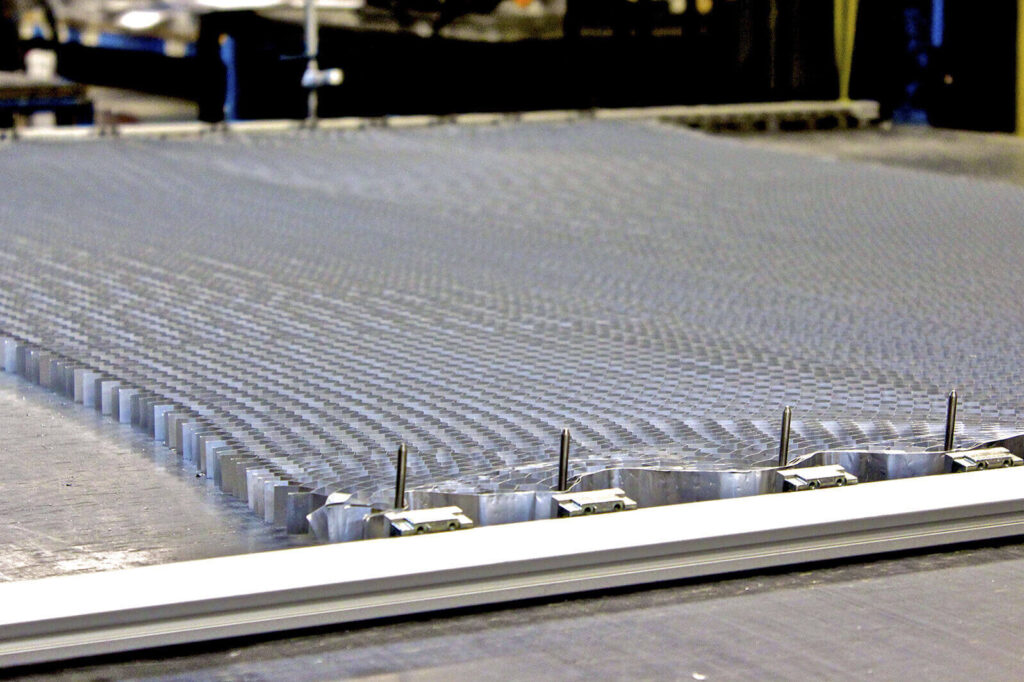

When larger sheets need to be expanded, Corex Honeycomb can supply a simple Hand Expanding tool, where two pullers are made by fitting movable pins onto rails. The pins are pushed through the last few end rows of the core at both ends. One of the rails is clamped to a table and the other one is pulled to expand the material.

- Machine Expansion

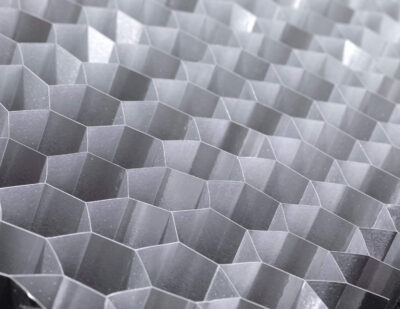

Automated expansion tables are used when smaller cell sizes, higher densities or thicker sheets of honeycomb in higher quantities need to be expanded. The amount of force required to expand the pieces is higher than the manual method can provide. Automated equipment is needed to provide enough force to expand the cells in a regular and even way.

Corex Honeycomb can supply aluminium honeycomb as blocks, unexpanded slices and expanded sheets. If you are considering purchasing unexpanded honeycomb, Corex can provide technical advice on the different expansion methods.

To find out more about the aluminium honeycomb expansion process or our range of aluminium honeycomb products, contact our sales team. Honeycomb core can also be purchased online in both expanded and unexpanded formats from the Corex Express shop.

This article was originally published by Corex Honeycomb.