eCon Engineering performed the strength analysis of a motor bogie and supported the design team with different simulation solutions during the development phase.

The analysis was based on the railway standard EN 13749 that describes the relevant load cases that represent different operating conditions of the structure. The loads can be separated into two main groups: exceptional- and operational loads. With the exceptional loads, the aim is to verify that the bogie does not suffer fatal damage as a result of an extreme load. While in the case of the operational loads, the strength of the bogie must be examined not only for static failure but also for fatigue due to the cyclic nature of the load. Since the tested bogie is a welded steel structure, the fatigue of the welds was investigated as a typical failure mode in terms of durability.

FE-Model and Boundary Conditions

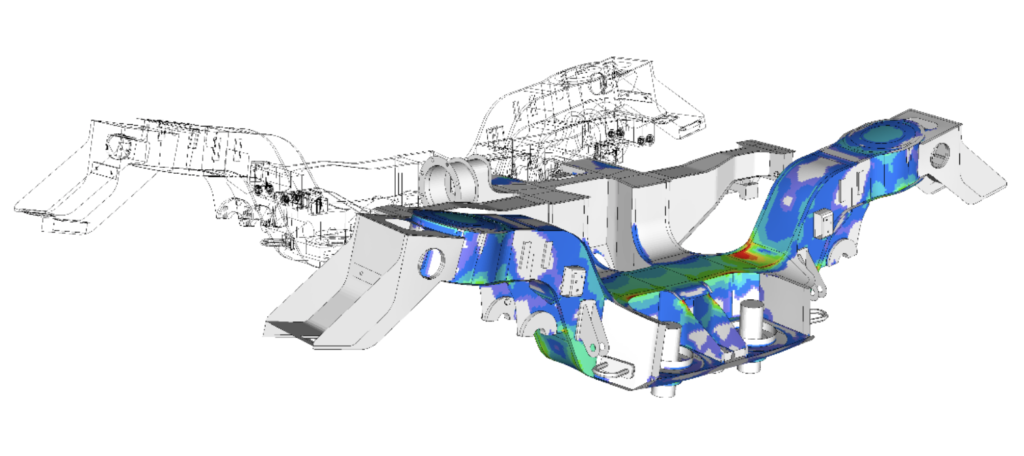

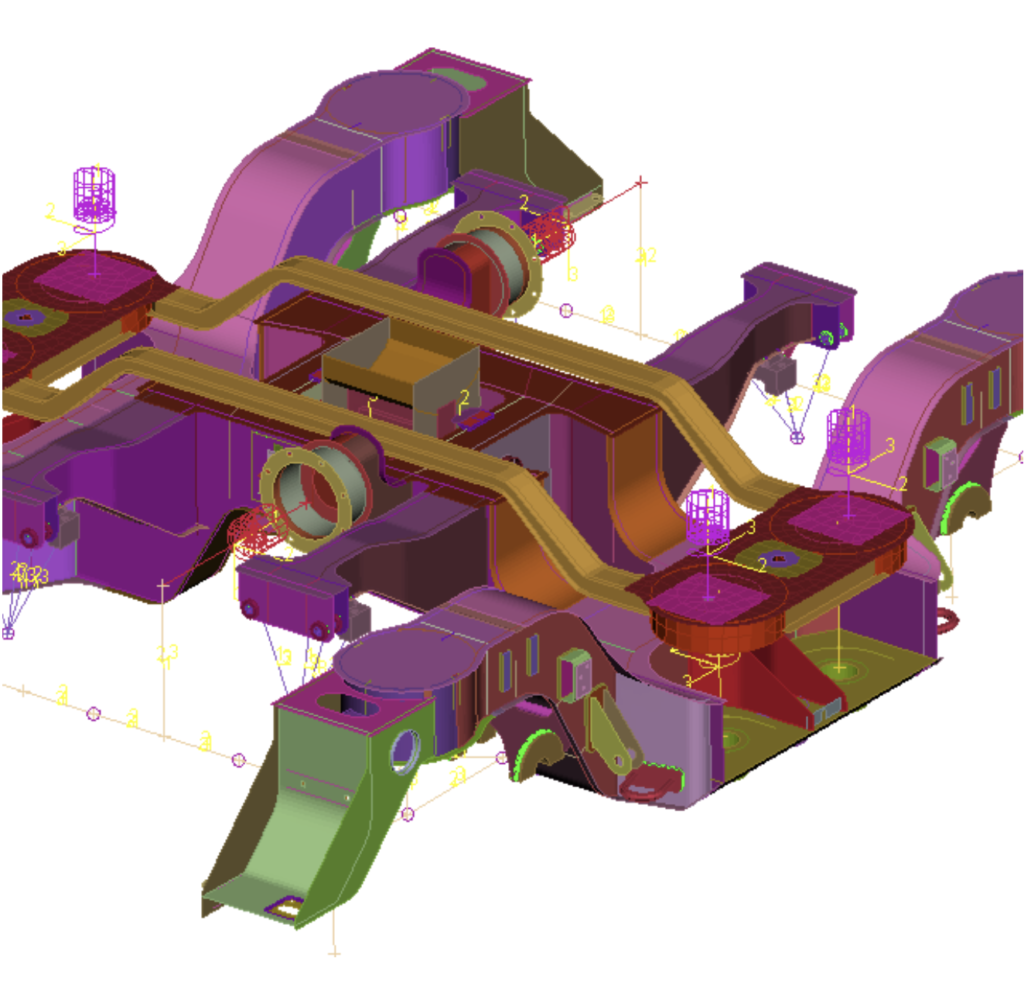

The behavior of the bogie under mechanical loads was investigated using a finite element model (FEM or FEA). A finite element model was built, including the whole bogie. The welded steel plates were modeled using shell elements, while some components were modeled using solid elements.

For proper force-transfer, it is important to support the bogie in the calculations accurately. For this, the suspension was modeled as a mechanism constructed of beam elements, while the stabilizing frame and the traction transfer components with shell elements. These parts were connected to the structure with joints and springs elements with proper characteristics, representing the steel and rubber springs. The boundary conditions and concentrated loads of the calculations were applied on these elements. Masses, mass-distribution as well as the material properties were set accurately.

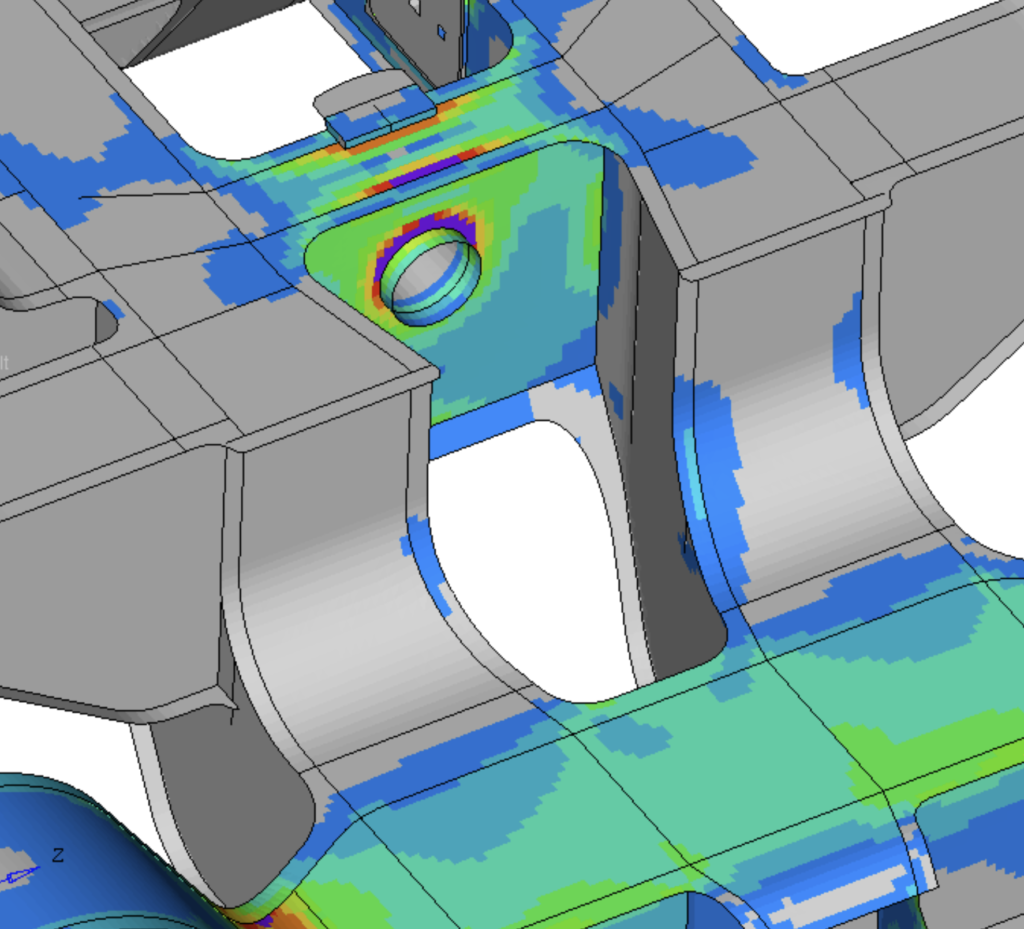

Result Evaluation

By analyzing the static failure, utilizations were plotted to the base material and the welding as well and safety factors were evaluated. In case of cyclic loads, the critical failure is usually a crack in the heat-affected zone at a weld-seam. Therefore, from the stress-results of the operational loads a fatigue evaluation is needed. By combining the different operational loads, a complete load-collective was created and the stress amplitudes and mean values were determined. Based on the stress results and defined cycle numbers for each load case, the fatigue evaluation can be made according to different welding standards and guidelines such as FKM, IIW, EuroCode3 or BS.

The presented simulation approach can be applied to different types of motor bogies and is an important method for the development of motor bogies, especially in the early design phase.