How pleasant it is to travel by train and admire the plain or mountain views from the window of the carriage. And what vivid photos you can take against the background of the tracks.

Do passengers think about the fact that the tracks need careful maintenance and repair, and what railway equipment is used to do this?

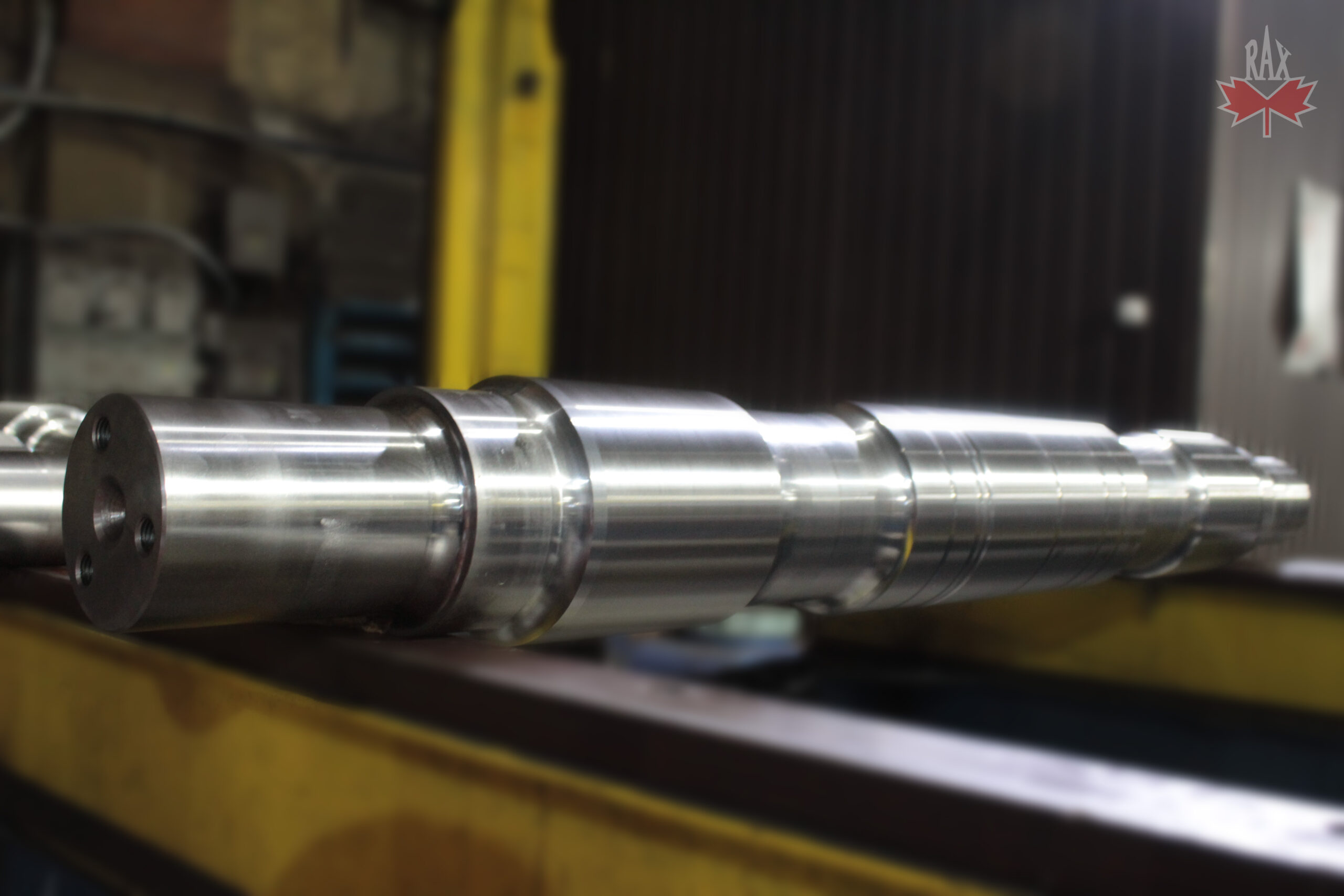

Construction and repair of railway tracks, maintenance and cleaning, and inspection of the technical condition of the tracks are carried out thanks to specialized rail transport. This powerful engineering equipment – track-laying and track-repair machines, ballast distributors and rubble-cleaning machines, machines for servicing the contact network, trolleybuses and inspection cars, snow-removal equipment, etc. – also moves along the tracks and requires periodic maintenance and repair, especially of the wheelset, including the axle. The axle of the wheelset is a key element of railway rolling stock, as it connects two wheels into a single structure, ensuring load transfer and stability of movement.

DDAP-RAKS produces axles of various levels of complexity for rail transport rolling stock, including for rail special equipment. DDAP-RAKS periodically ships axles for rail special transport wheelsets to European customers. Such railway axles have a complex geometry, including cylindrical sections with different diameters, conical transition zones with complicated processing conditions, structurally complex parts of the axle hub and journal, as well as end technological holes of different depths.

For enterprises that repair railway special equipment or form wheel sets for it, it is important to supply axles within strictly stipulated terms, sometimes within short terms. And taking into account the peculiarity and diversity of the fleet of special equipment and the small number of each type, a minimum assembly batch of axles may also be required. The production capabilities of DDAP-RAKS fully cover these needs – we ensure stable supplies even in short terms, manufacture axles in batches required by the client and guarantee exact compliance with the customer’s drawings. Our approach allows us to effectively serve both large repair depots and specialized enterprises with individual requests.

Thanks to 30 years of experience in axle production, a high-tech fleet of CNC equipment and a team of qualified specialists in the field of metalworking, we confidently solve technological tasks of varying complexity. Therefore, DDAP-RAKS has become a reliable partner for companies that service or operate a fleet of special railway transport.

This article was originally published by DDAP-RAKS.