As global rail systems strive for greater durability, comfort and environmental responsibility, engineers increasingly focus on components that support performance and sustainability.

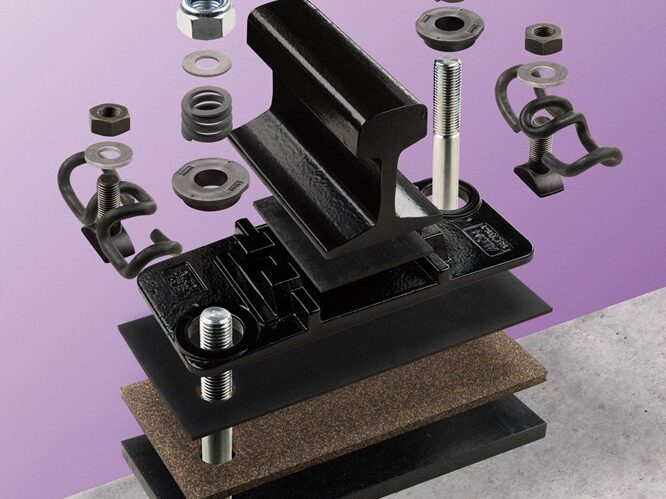

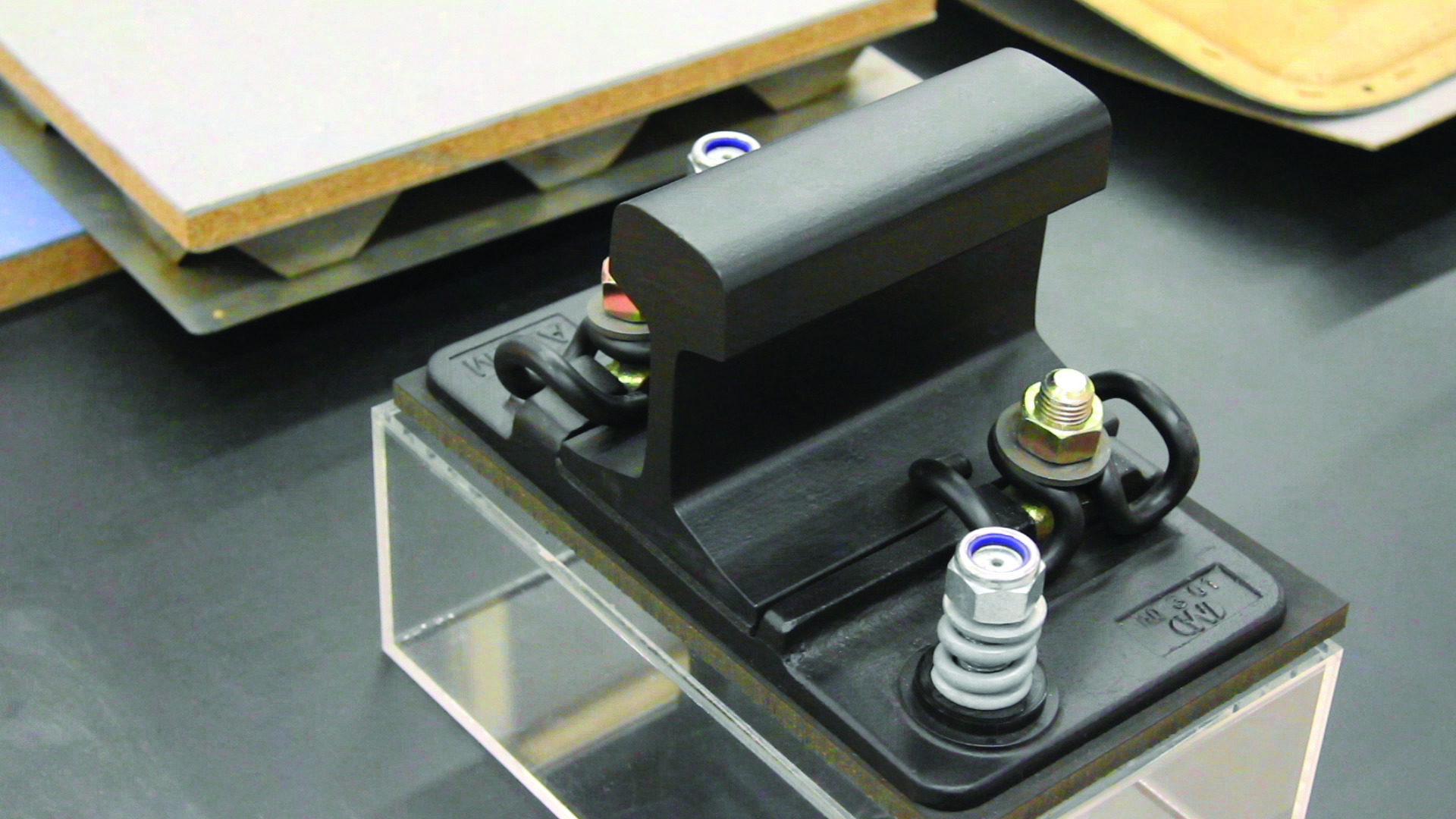

Two such components are the rail pad and the baseplate pad. The rail pad, a resilient layer placed between the rail and the sleeper, and the baseplate pad, which interfaces between the rail and its supporting structure, play key roles in load distribution, vibration attenuation and noise control. Among the materials used for their production, cork and rubber composites stand out – not as a novelty, but as a time tested, reliable solution with proven use in railway infrastructure.

One of the leading companies in the development and supply of cork-rubber composites for railway applications is Amorim Cork Solutions. With decades of experience engineering advanced cork-based solutions, Amorim is dedicated to implementing high-performance, sustainable vibration control technologies for the railway industry.

Cork and rubber have long been explored for vibration control due to cork’s unique mechanical properties, namely its high compressibility, excellent elastic recovery and natural damping capacity. Significant industrial development has been directed toward corkbased composites for several technical applications. In recent decades, cork-rubber materials have been engineered for use in railway systems, including rail pads and baseplate pads, with proven benefits in vibration attenuation and durability. These composites continue to evolve, with enhanced resistance to mechanical fatigue, temperature variation and environmental stressors – while retaining cork’s natural performance advantages.

Rail Pad Functions and Requirements

Rail pads serve several essential purposes in the railway context, and over time need to endure millions of cycles of compression, demanding not only high durability but also stable long-term performance. Considering the technical characteristics of the material, rail pads should distribute vertical loads and vibrations from passing trains, protecting sleepers and ballast, dampen dynamic loads, reducing track wear and fatigue, minimising structure-borne noise transmission and accommodating track irregularities and minor alignment deviations. To fulfil these functions, the material must combine high resilience and recovery under repeated loading, shear modulus suitable to manage rail-seat stiffness, resistance to weathering, oils and UV exposure and have long-term fatigue and aging resistance. Considering cork and rubber composites, the combination results in a material that performs well under the demanding cyclic loading of rail traffic, namely due to the unique synergy between cork and rubber. Cork contributes natural compressibility, low density and intrinsic damping while rubber provides elasticity, mechanical strength and resistance to wear and fatigue. The properties that this combination can achieve make them highly suitable for both high-speed rail and urban transit systems.

Cork-rubber rail pads have been installed on Amsterdam’s Metro Line 52 (North-South Line). This line employs the Alom NZL49 rail fastening system, which integrates cork-rubber rail pads and baseplate pads from Amorim Cork Solutions.

Mark Rijen, Chief Technical Officer & COO of Alom, said:Amsterdam is a very old city, mainly built on piles, which posed big challenges for the metro line. We had to meet highly demanding specifications for both noise and vibration control, as well as ensure that the level of adjustment in the complete rail fastening system can compensate for any future settlement in the drilled tunnels. The 49NZL rail fastening system is a proven solution, certified according to EN 13481-5 Category A, and we successfully designed it to be maintenance-friendly by reducing the number of components.

The combination of cork and rubber in the vibration control pads and baseplate pads not only dampens sound and vibrations but also reduces the environmental footprint of the project, since cork is a natural CO2 retainer.

Cork-rubber composites have shown superior performance compared to elastomer-only alternatives, especially in maintaining mechanical properties over time and in variable temperatures.

Mark said:Cork is also virtually inert and very stable within the wide temperature range of rail applications without compromising the properties of the complete product.

This helps explain the enhanced durability and consistency observed in these composites. Several studies have investigated the mechanical behaviour of cork–rubber composites under various conditions. For instance, research published examined how the addition of cork to rubber compounds affects their mechanical properties. Lopes et al. (2021) found that incorporating cork granules into natural rubber increased hardness and static stiffness while maintaining similar dynamic behavior compared to the base rubber compound. Moreover, the composites demonstrated stable performance under compressive loading, indicating enhanced durability over time.

Additionally, research has shown that cork–rubber composites exhibit favorable damping characteristics across a range of frequencies and temperatures. For example, a study investigating the shear modulus and loss factor of cork-rubber rail pad materials found that these composites maintained consistent damping properties over a frequency range of 200–2500Hz and temperatures from -20°C to 40°C. Cork-reinforced rubber showed more predictable behaviour across temperature ranges and higher damping at low temperatures which may help maintain consistent noise levels and mechanical performance year-round. The change in the loss factor also showed a more complex but more predictable behaviour, which can be engineered for better performance. These findings suggest that cork-rubber composites offer superior performance in maintaining mechanical properties over time and under varying temperature conditions compared to elastomer-only materials.

Environmental and Lifecycle Benefits

Cork is a material that is harvested without harming the cork oak tree. It is primarily sourced from the Mediterranean region, from the cork oak tree (Quercus suber), that has a unique ability to regenerate its bark after harvesting, making it one of the most sustainable raw materials available. Its integration into technical composites supports a reduced CO2 footprint compared to synthetic-only elastomers, a long service life – leading to fewer replacements and less track downtime. Furthermore, these composites support key European sustainability goals outlined in the European Green Deal, the Circular Economy Action Plan, and the EU Biodiversity Strategy by using renewable, carbonnegative materials that reduce reliance on fossil-based inputs. Furthermore, they align with Green Public Procurement (GPP) guidelines using sustainable raw materials, enhanced durability that lowers life-cycle costs, and compatibility with environmental product declarations (EPDs), contributing to more sustainable and responsible infrastructure development.

Far from being a recent innovation, cork and rubber composites are a mature, proven technology that continues to evolve. In rail pad and baseplate pad applications, they deliver robust mechanical performance, effective vibration damping and environmental advantages that make them ideal for modern rail systems. Their success over decades and geographies confirms that this natural-engineered combination remains one of the most intelligent and sustainable choices in railway track design.

About Amorim Cork Solutions:

At Amorim Cork Solutions, we develop solutions that incorporate high-performance cork composites, combining innovation and sustainability. We use cork – a 100% natural, renewable and recyclable raw material – to develop ground-breaking solutions for various industries such as aerospace, maritime, mobility, sealing, energy, construction, railway, flooring, sports surfaces, playgrounds, toys, home, office and leisure. Every innovation reinforces the promise of a future where nature and technology coexist in perfect harmony.

This article first appeared in the Railway-News Magazine Issue 2 2025. Download the full PDF version here.