Autonomous Track Inspection: Keeping Railways Moving Safely and Efficiently

The railway industry is entering a new era of autonomous track inspection that couples frequent inspections of track with defect detection and software analysis capabilities, which in turn optimise railway maintenance and renewal planning, reduce risks through earlier identification of track defects, and improve rail network safety.

Data Collection: Autonomous Systems Offer a Highly Efficient Solution

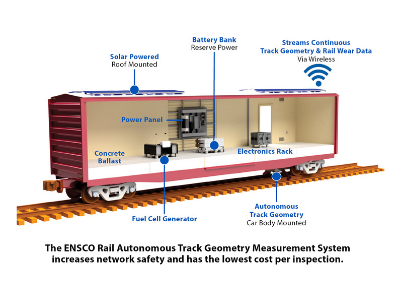

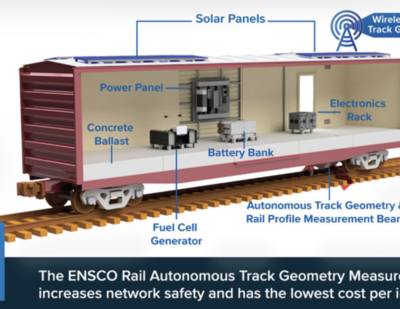

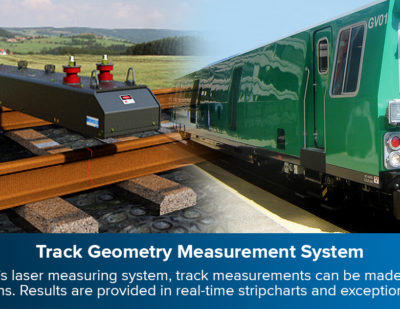

Today, autonomous inspection systems provide reliable, fully autonomous inspection installed on passenger or freight cars used in revenue service.

One of the most significant advantages of autonomous inspection technology is that every movement of the host train offers an opportunity to evaluate the track, allowing for more frequent inspections without track time being consumed by dedicated inspection vehicles.

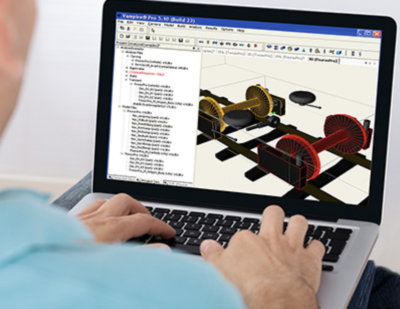

ENSCO Rail autonomous track inspection platforms now provide a full range of capabilities to the industry to evaluate track geometry, rail wear, vehicle-track interaction, and machine vision inspection of the track and its components. These platforms utilise precision location determination hardware coupled with advanced linear referencing algorithms to assign track locations and apply appropriate location-based defect threshold limits. The technology employs unique data compression algorithms to stream large amounts of information to the cloud in near real-time for short and long-term maintenance planning.

More Reliable Detection through Artificial Intelligence

One inherent challenge faced by autonomous track measurement systems is that certain conditions or track features can mimic defects, when in fact, track conditions are normal. To remedy this, ENSCO Rail developed advanced artificial intelligence algorithms that recognise and filter out these false exceptions.

The algorithms are based on human data editors from thousands of miles of actual survey data, from which the ENSCO Rail algorithms learned to edit out false exceptions for real-time reporting.

Big-Data Analytics Offers Condition Trending and Data-Driven Maintenance Planning

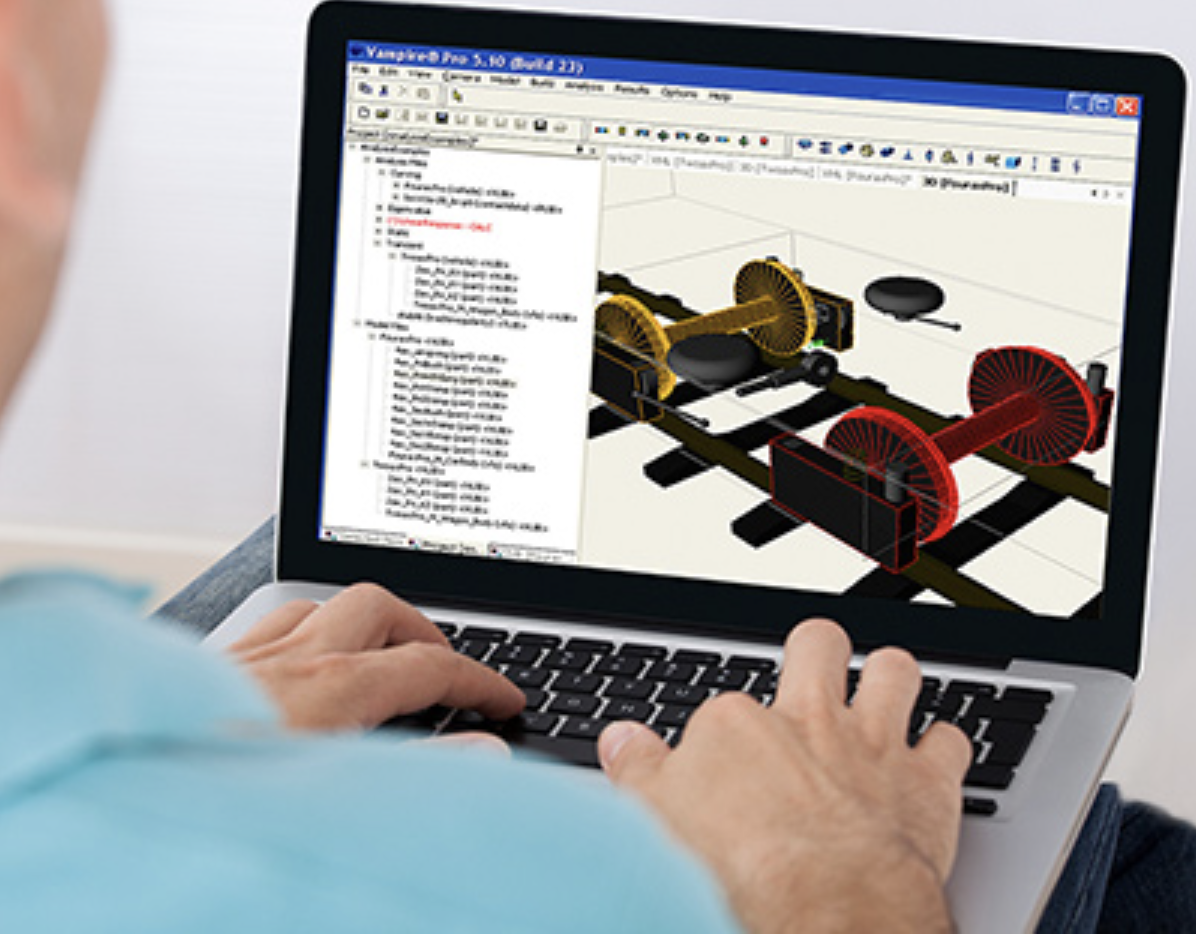

Maintenance is a necessary and significant expenditure by railway personnel. Taking a proactive approach to maintenance and asset planning can yield significant savings by reducing manual condition data analysis and unnecessary maintenance expenditures.

New asset condition technology that relies on artificial intelligence, machine learning and data analysis offers the potential for significant reductions in maintenance costs every year while increasing operational capacity through accurate application of maintenance tasks.

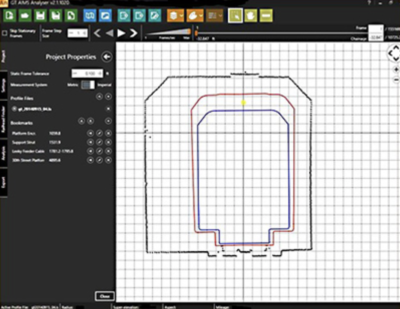

The ENSCO Rail Automated Maintenance Advisor (AMA) automatically identifies areas of poor track performance, determines trends in track condition deterioration and translates that data into prescriptive maintenance tasks, resulting in proactive and data-driven track maintenance planning and sound, efficient maintenance decisions.

Fully automated and cloud-based, the AMA is flexible and configurable to railway customer deterioration trending needs. It operates automatically, routinely assessing track condition data and recommending maintenance tasks based on specified maintenance strategy. Asset management plans include rail grinding, rail replacement, ballast renewal, tamping and turnout maintenance requirements.

Visit www.ensco.com/rail and follow us on LinkedIn to stay up-to-date on the latest innovations in rail safety from ENSCO Rail.