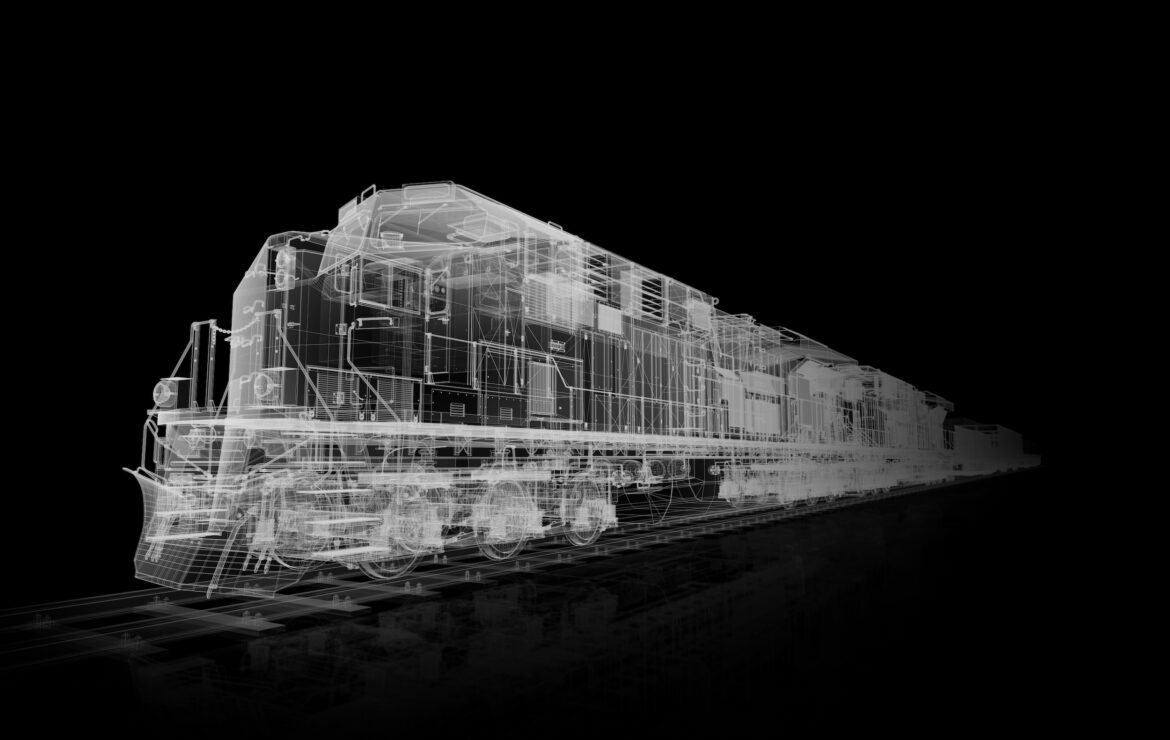

HEGENSCHEIDT-MFD-Reprofiling: Underfloor Machining of Wheelsets

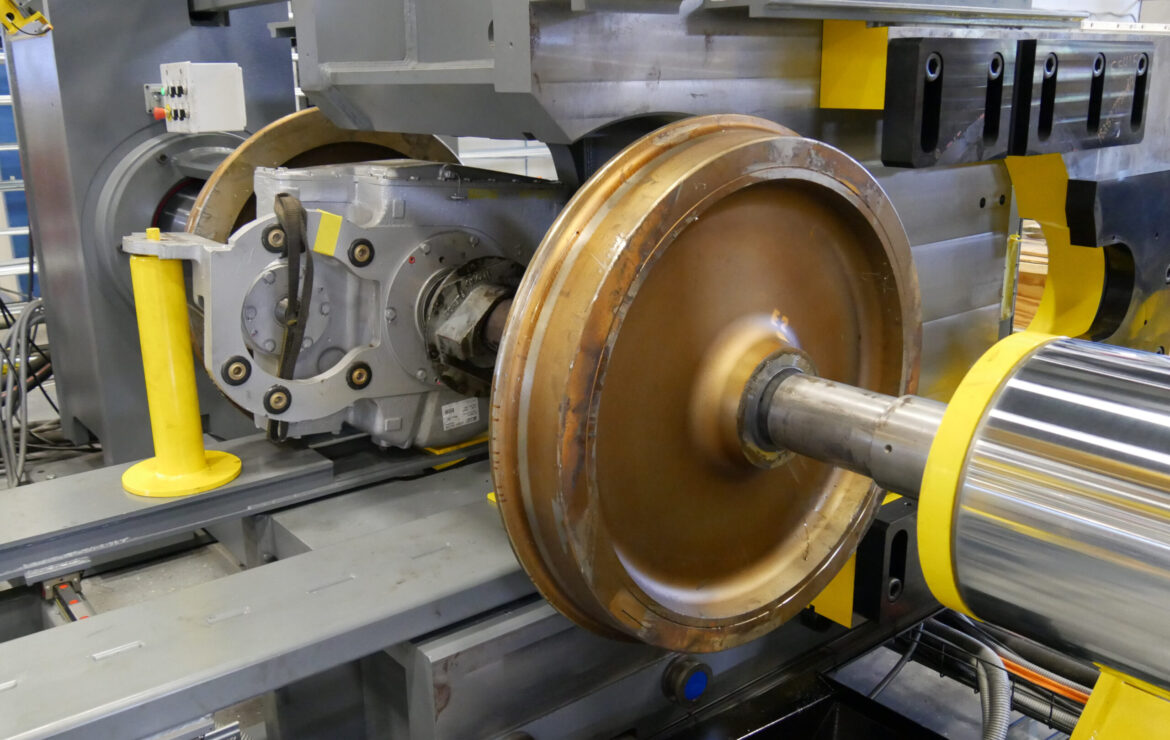

We were guests at the Karlsruher Verkehrsbetriebe. As a customer of our subsidiary HEGENSCHEIDT-MFD, they use the U200-400 underfloor machine for wheelset machining.

The U2000-400 is a universally applicable, dynamically rigid and operator- and service-friendly wheelset lathe. It represents the state of the art in wheelset machining technology. The machine’s high degree of utilization, precision, long service life and minimal maintenance costs guarantee ideal cost-effectiveness.

HEGENSCHEIDT-MFD underfloor wheelset lathes machine, both wheelsets of high-speed trains of railway companies and wheelsets of local commuter trains in the installed and dismantled state by reprofiling to the highest degree of accuracy.

The machine is operated by a means of one central control panel so that the operator has continuous access to all machine functions in an ideal working position. During machining, the operator is protected from flying chips. The automated machining takes most of the work out of the operator’s hands, making the machine easy to operate.

A tandem version – U2000-400D – is also available for the simultaneous machining of bogies with mechanically non-coupled axles. The new patented double tandem U2000-400Q enables simultaneous machining of two bogies.

Read about HEGENSCHEIDT-MFD’s reprofiling here.