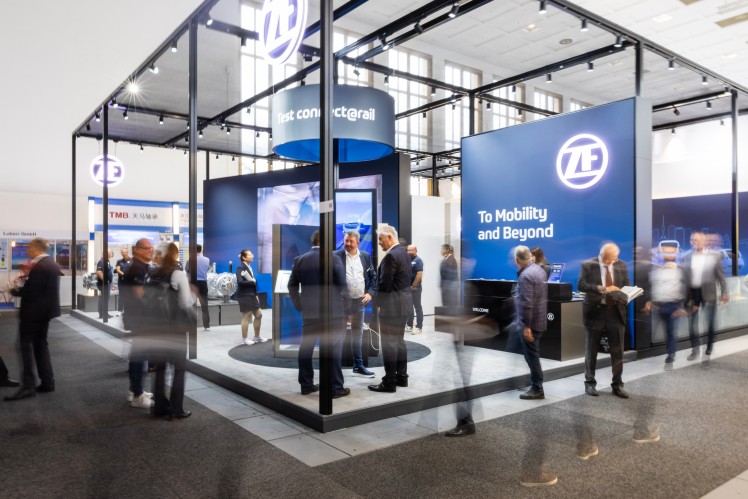

connect@rail – ZF’s Digital Condition Monitoring System for Rail Vehicles

With connect@rail, the condition monitoring system for driveline components and track infrastructure, ZF supports smooth operation in the rail network. The system is based on Heavy Duty TAGs. Mounted in the bogie, these Bluetooth-based sensors record acceleration data at the wheels and transmit it to telematics gateways. The information is aggregated and sorted there before being sent to the ZF Cloud for final evaluation.

Via a customer-specific dashboard, operators can view this data visualized for prediction purposes and then identify potential sources of malfunction at an early stage. Necessary maintenance work can therefore be planned in a predictive manner, which prevents delays in the running operation due to unplanned breakdowns.