Inspection and Measurement Systems for Rail Application

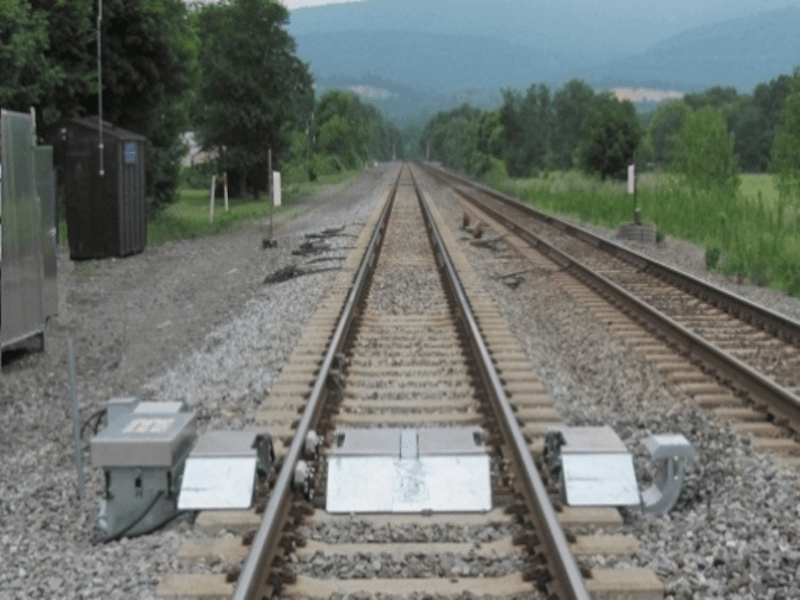

The WISE family of Wayside Inspection Equipment, IEM, has developed the broadest family of wayside inspection and measurement technologies in the rail industry. IEM provides operators with automated, real-time, continuous remote measurement and inspection of critical components.

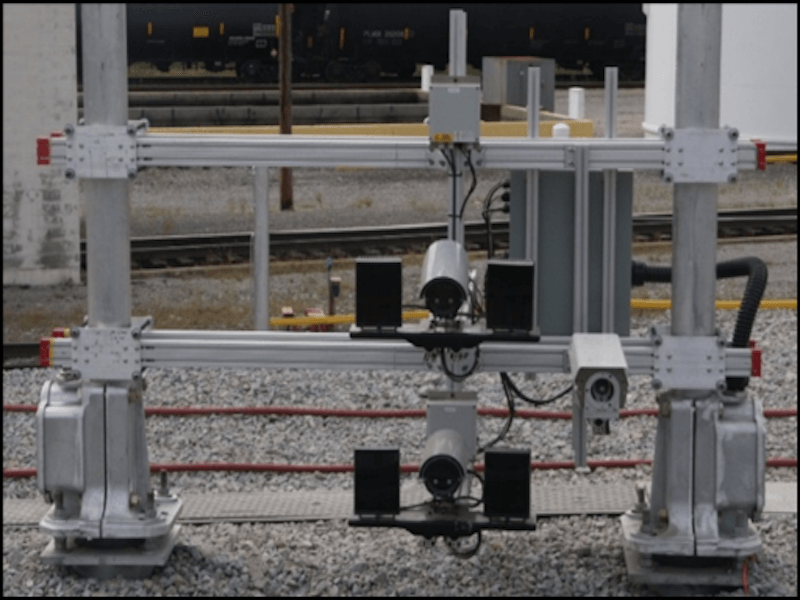

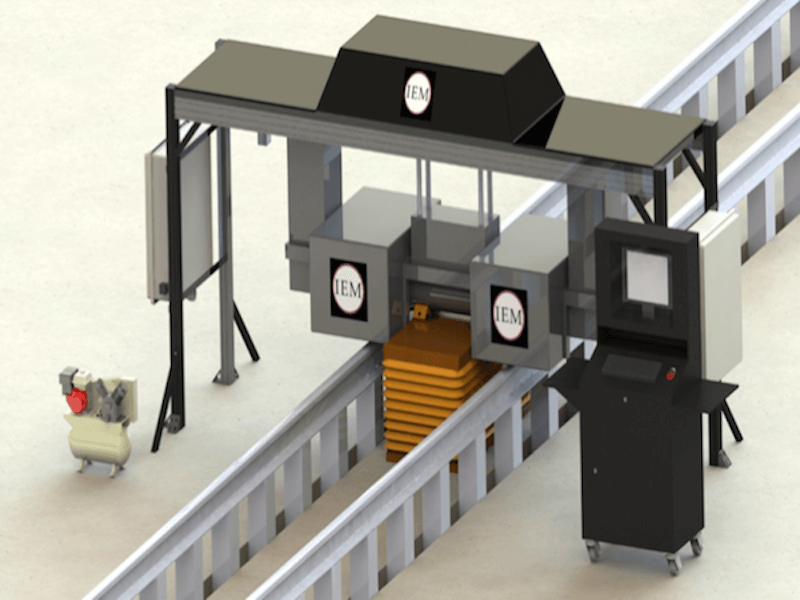

The WISE SuperSite

IEM offers the largest integrated family of wayside inspection technologies which can be installed in “Super Sites”. Since virtually all the components have been developed in-house, they all share common operating systems and communications protocols, easing system integration and reducing long term maintenance costs.

Train Inspection Components

The WISE Family of Wayside Inspection Equipment represents the most comprehensive set of integrated truck/bogey/wheel/brake/bearing inspections components in the world today.

The foundation of the system is the Wheel Profile/Diameter system which provides readings of flange thickness, flange height, rim thickness, wheel diameter, back to back distance, flange angle, and rim profile.

Add-on components to the WISE Main Line SuperSite system include:

- Brake Disc/Pad/Shoe Measurement

- Wheel Flat Measurement System Using Vibration Sensors

- Dragging Equipment Detector

- Truck Performance Module (TPM)

- Wheel Flaw Detection System, WISEFlaw™ using Machine Vision,

- WISE Weigh-in-Motion

- Train Infra-Red Inspection System Module (TIRIS) to detect hot/cold wheels, overheated bearings, sliding wheels, and stuck brakes.

Handheld/Portable Gauges

- Electronic Wheel Gauge

- Ultrasonic Axle Flaw Detector

- Wheelset Back to Back Gauge

- Laser Back to Back Gauge

- Wheelset Back to Back Gauge

- Wheel Diameter Gauge Model D16

- Wheel Profilometer

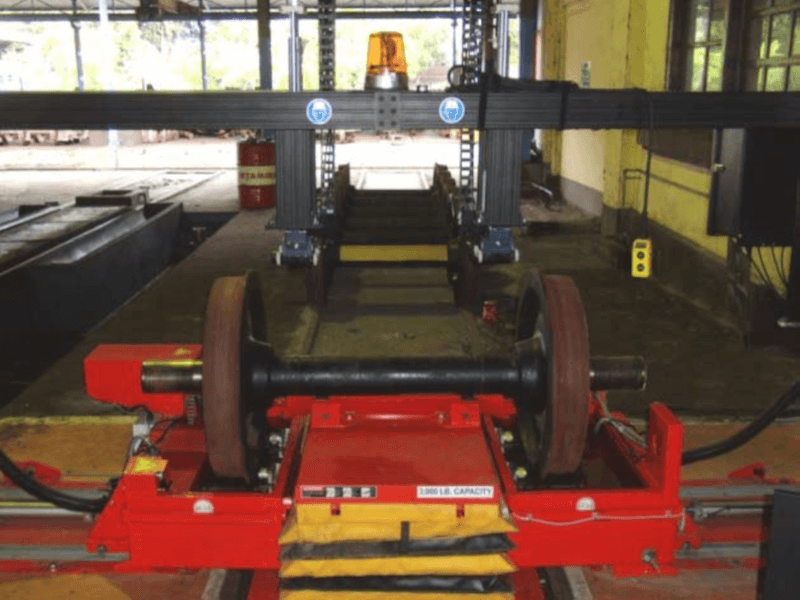

WheelShop Automation Inspection and Certification Equipment

IEM provides a set of inspection and certification stations for wheelshop automation. They include ultrasonic inspection stations for both wheels and axles, and in-bound wheel defect detector based on machine vision, an in-bound axle geometry/wear inspection station, and an out-bound wheelset certification station based on machine vision.

Ultrasonic Wheel & Axle Inspection

IEM’s Flaw Detection Stations ultrasonic phased arrays to inspect the wheel for cracks, flaws and defects.

IEM’s Axle Inspection Module uses ultrasonic phased arrays to interrogate the solid axle rod of a wheel set in a workshop environment. Two phased-array ultrasonic transducer assemblies allow for the inspection of the critical areas of the axle, namely the wheel seat and bearing seat. This state-of-the-art design uses a two-probe design with ‘beam steering’ to replace the older-style four-probe design.

Axle Geometry Inspection

The measurement stand will rotate the axle and take the following measurements based on the AAR Wheel and Axle Manual—Figure 4.3. It will also check for “bent condition” and out of center condition in conformance with paragraphs 1.2.1 and 1.2.2 of the Wheel and Axle Manual. G at three places.

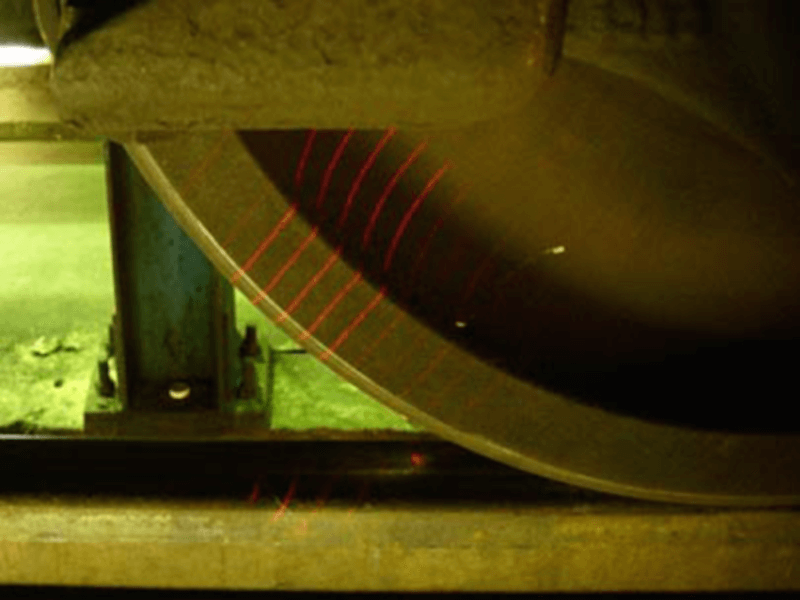

Wheel Defect & Profile Inspection

The wheel defect inspection station would be positioned at the entry to a wheelshop and would take critical measurements of surface defects and profile to determine the disposition of the wheel ie true/scrap.

IEM’s True Vision technology generates a computer model of each wheel, then computes the measurements for flange thickness, flange height, rim thickness, flange angle, diameter (tape size), radial run out, plane run out, and back-to-back reading.

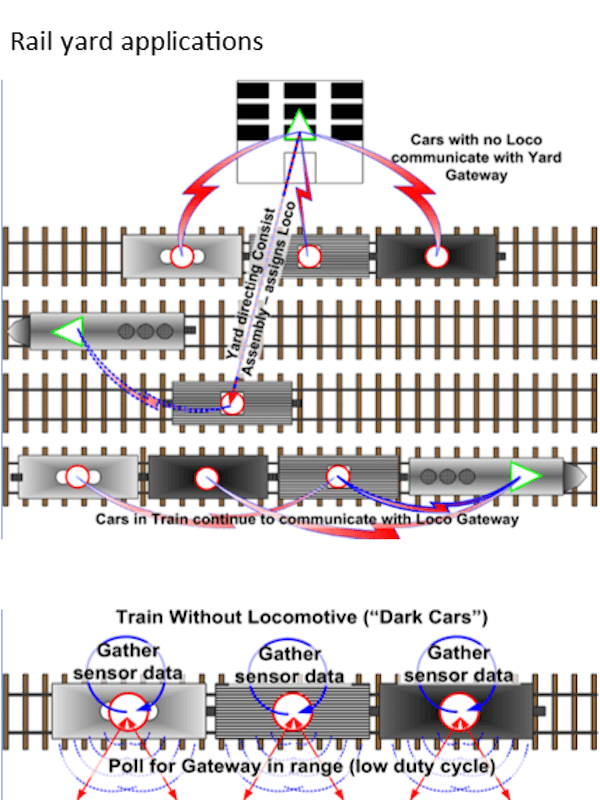

Ideas in Development –Applied Research

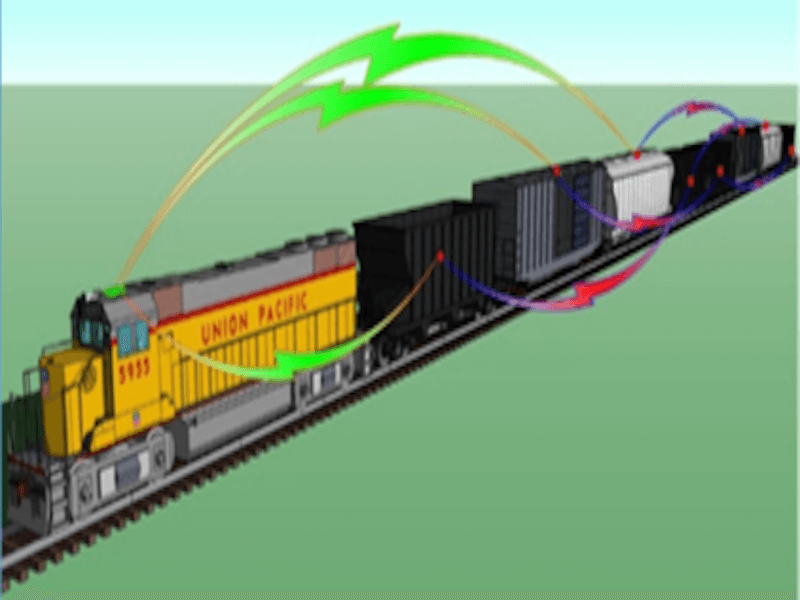

- WISENet™ Wireless Sensor Network

For Onboard Monitoring Self-powered onboard sensors, mounted on individual cars, communicate between one another and a central gateway to measure, store, evaluate and report data for remote diagnostics. WISENet reacts to the constant movement of cars between trains and various locations within rail yards by identifying specific cars and maintaining connectivity. A single device links the entities within a secure, computerized network.

- Smart Sensor Security Systems

IEM provides comprehensive security solutions which detect, identify and track suspicious activities in a variety of transportation settings.

“Smart” video surveillance makes intelligent decisions about observed activities. Fused visible/infrared cameras enhance the ability to interpret observed activities. Advanced acoustic monitoring identifies specific sound signatures and isolates probable source direction. Software integrates these subsystems with other existing security technologies for full customization.

- Smart Grade Crossing Monitoring System

“Smart” video surveillance and analysis detects and reports on pedestrians and vehicles at grade crossings.

- Contactless Wheel Gauge

Contactless Wheel Gauges take all basic wheel wear measurements with a non-contact instrument.