Train and Track Inspection Systems

Beena Vision Systems Inc. is the leading manufacturer of vision-based automatic wayside inspection systems for the railroad industry. Over the last sixteen years, Beena Vision has pioneered and developed a number of innovative products using sophisticated machine vision and non-contact measurement technologies. These products are specifically designed to provide valuable information in a variety of areas to effectively assess railcar components and track safety conditions. Although Beena Vision’s product line mainly concentrates on automatic wayside train Inspection systems, it also offers on-board rail and track measurement and inspection systems, together with handheld products for wheel and track measurement.

Our wayside train condition monitoring systems are designed and manufactured for the most demanding applications. We take pride in our high levels of accuracy and system availability. Our systems have a reputation for being tough and durable even in the heavy haul railway environment. This has been the result of years of design, testing, and field experience with more than one hundred installed systems worldwide. Beena Vision has installed numerous systems at all major American Class 1 railroads including BNSF, UP (Union Pacific), NS (Norfolk Southern), CSXT and has worked closely with AAR/TTCI in developing new technologies. Large numbers of our systems are successfully deployed in Australia, Europe, China, South America, and the Middle East. Beena Vision in its state of the art “Technology Centre” in Norcross, GA, USA, has an extensive R&D program to develop additional advanced systems for automatic monitoring of several critical components of freight and passenger cars, bogies, locomotives, and track components. The company was formed in 1996 by company President and owner, Kambiz Nayebi PHD. Dr. Nayebi was previously a professor at the prestigious Georgia Institute of Technology, where he taught signal processing engineering. Dr. Nayebi saw an opportunity to bring the well-developed science of image processing with systems for collection, inspection, measurement and reporting to the Railway industry. The hope was to enhance the labour intensive and often inconsistent manual inspection processes currently used by the railways.

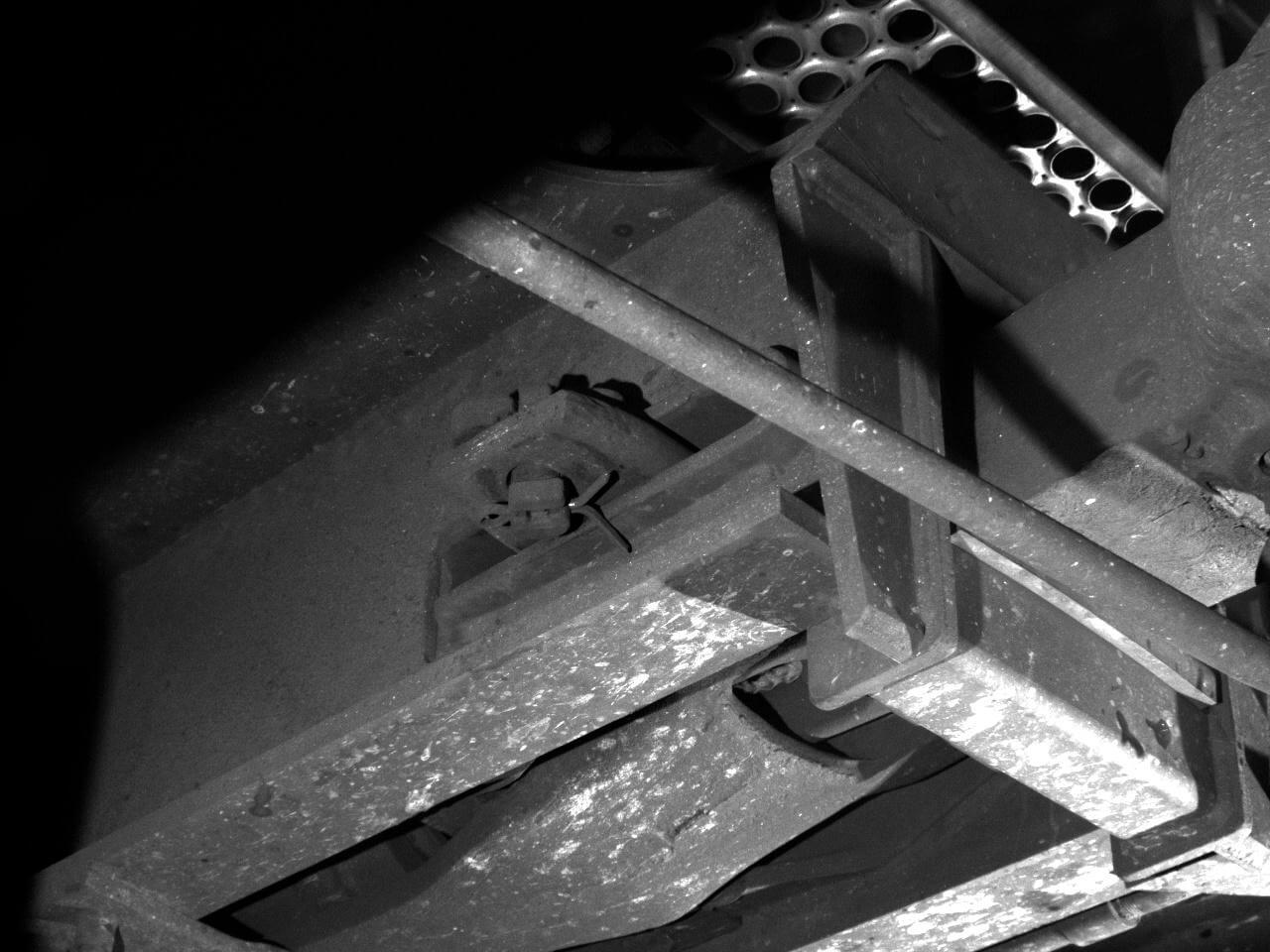

Wheelview, Brakeview, TruckView

The cornerstone product designed and manufacture by Beena Vision is the “WheelView” a dynamic wheel profiler that can be installed in the main track and which can profile and measure wheels at speeds up to 80 mph. The profile and the measurements recorded are used to detect wheels not meeting industry standards, and most importantly, the data can be used for predictive maintenance. This results in a fleet of wheels that are known to meet the minimum standards and wheel replacement are able to be scheduled to reduce downtime for the equipment. Similar equipment is the “BrakeView” and “TruckView” which perform measurement functions for the brake shoes (either tread shoes or disk shoes) and the truck or bogey friction wedges. The TruckView system is also able to be used in evaluation of the condition of springs and detect “sliding wheels”. Please watch the below videos to see our Wheelview and Couplerview in action :

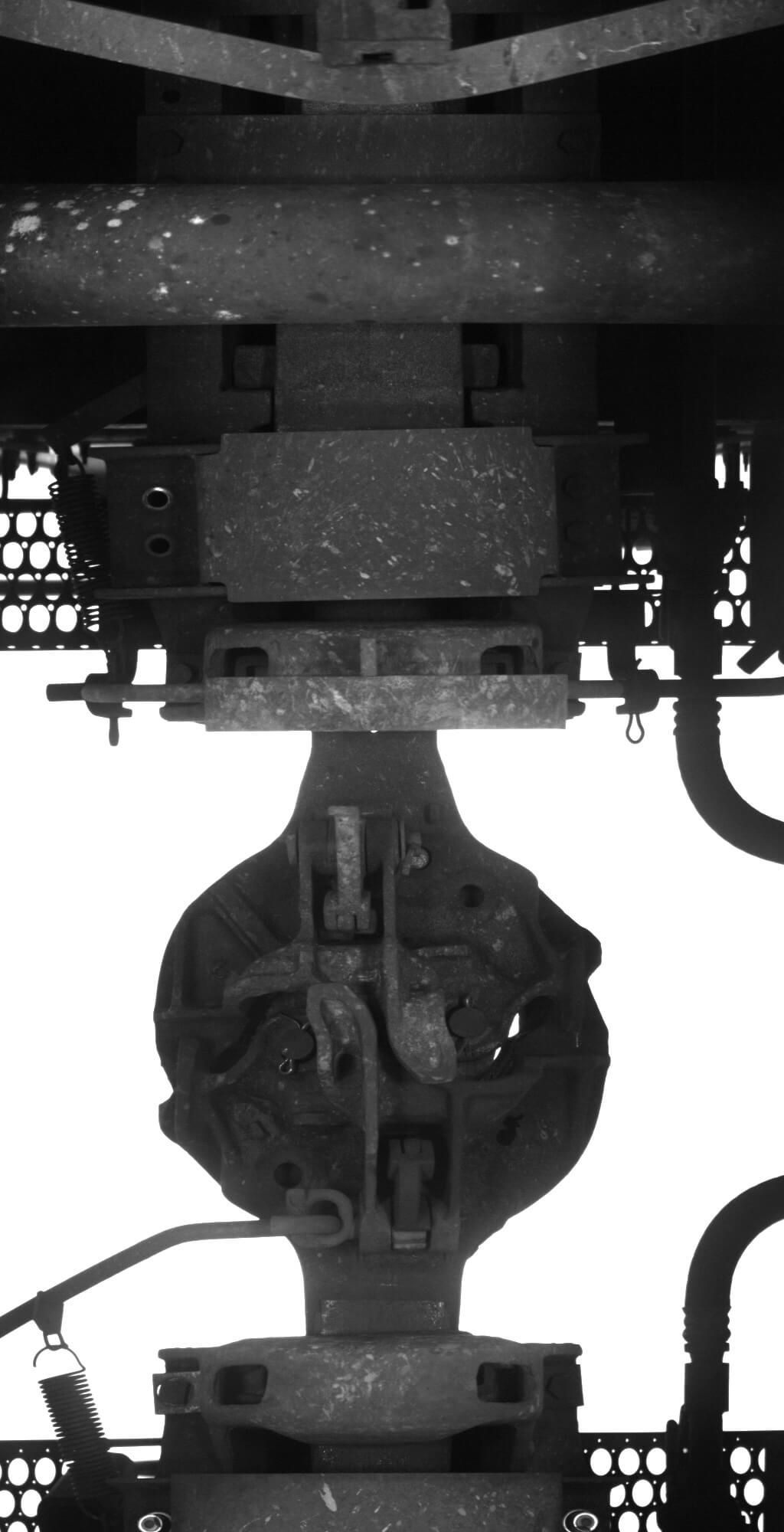

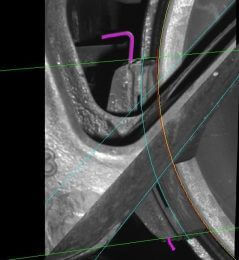

Couplerview – Pin Measurement and Retainer Measurement Systems

The “CouplerView” consist of a pair of systems; The “Coupler Pin View “inspects and evaluates the North American “F” shank couplers. It accomplishes this by targeting the pan that retains the coupler pin that keeps the coupler in the car. Finding a defective retainer plate can prevent the coupler from “pulling out” of the car, causing a delay in the best case, or a derailment in the worst case. The second system in this group is the “Coupler Cross Key” inspection system which evaluates the retainer system on the North American “E” type coupler shank. It sits outside the gage of the track and images and evaluates the cross key and its retainer and can find things such as a missing cotter key, missing retainer, or the case where the key has begun to work out of the car. This system also can prevent delays or costly derailments. These systems also are installed in the main track and can operate at speeds in excess of 80 mph.

CSCView – Car Component Monitoring

The “CSCView” monitors the Car Structural Components on trains moving at track speeds on the mainline. Like the previous systems, it can operate on moving trains at speeds up to 80 mph. This system uses line scan camera technology and proprietary algorithms to create a single digital image the length of the train. Then using wheel sensors and AEI information the cars are separated and made available for inspection in a viewer that allows controlling the speed at which the image move by, as well as stopping the image and zooming for greater detail. The software allows the insertion of notes and the transfer of images with notes for the purposes of emails etc. There is presently an ongoing development that will result in a “smarter” system that will recognize certain defects and present them automatically. The “CSCView” system is designed to operate with the “TrainView” system. These two systems combined form a unit that can inspect a moving train in a plane 360 degrees around the train, giving high definition imaging of top, sides, and underneath the car.

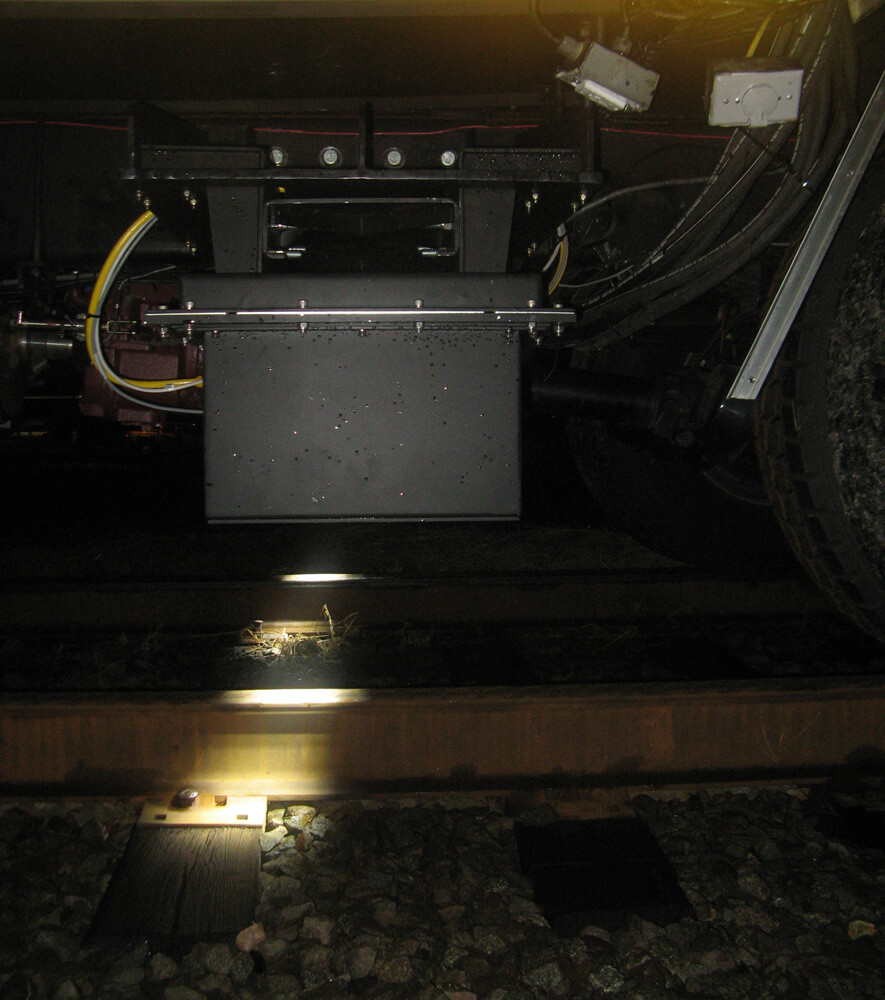

TrainView – High Resolution Vehicle Inspection

Beena Vision offers TrainView as a full scale train imaging system as part of its comprehensive train inspection systems. This system consists of multiple line and area scan cameras that provide images of the train at track speeds with high resolution. The system is designed to provide images of all externally visible components of a car. The images are then assigned to individual cars based on the AEI data. Car components are then ready for viewing and analysis or auto processing. The system uses several sensors together with algorithms to pinpoint axle position, car beginning and car end positions, car components such as safety appliances, ladders and handholds, hopper door and their handles, brake hose, truck components such as side frame, springs, and car components such as brake,

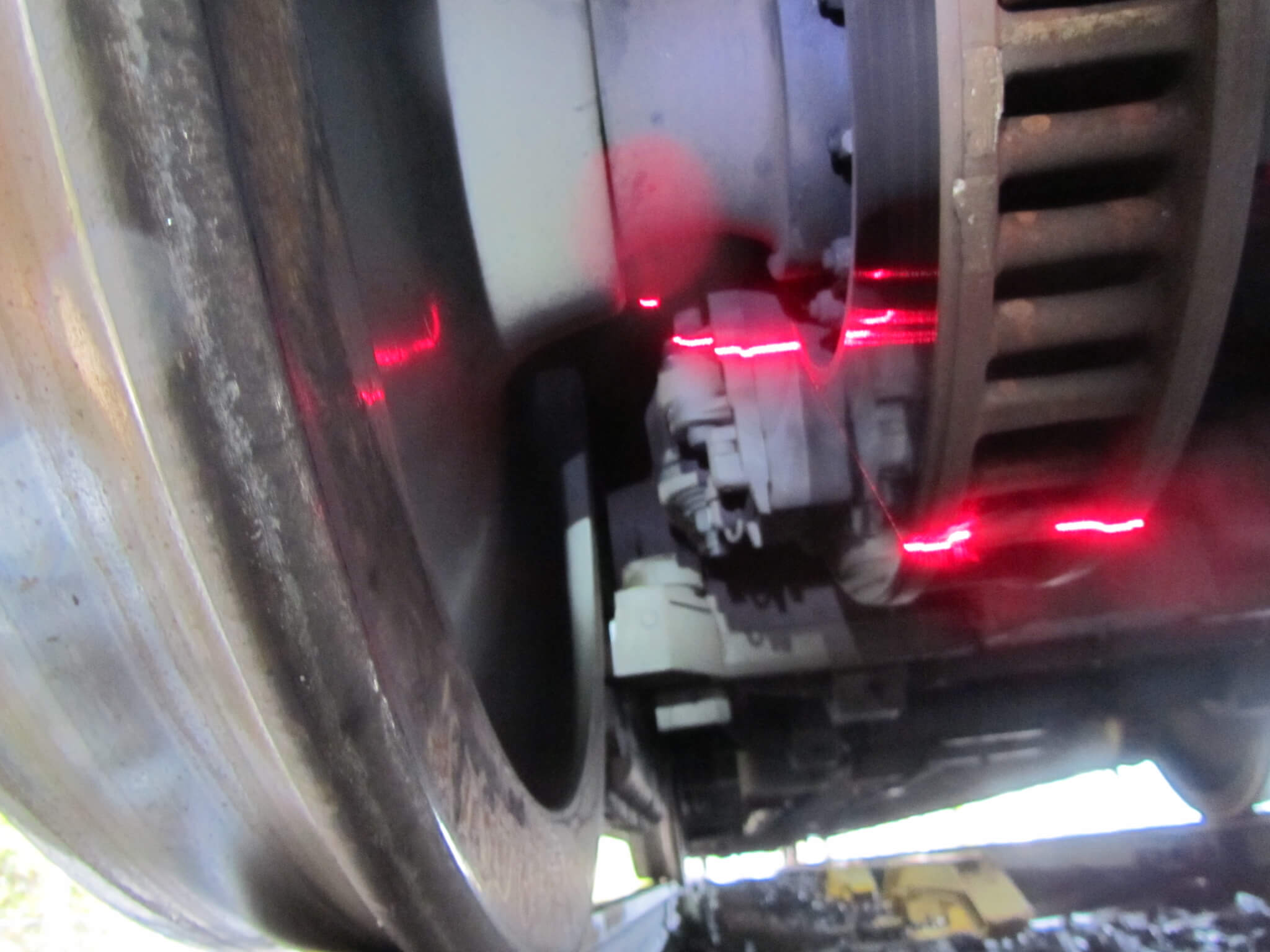

TreadView – Whole of Wheel Rolling Surface Monitoring

TreadView is an automatic Optical Wheel Surface Inspection System. TreadView is designed to inspect wheel tread surface and flange area at normal track speeds. This system offers visual inspection of complete wheel tread and flange surface using optical imaging and laser scanning. The objective of the system is to determine any surface abnormalities of the wheel surface that can be detected using a high resolution imager and a high speed laser scanner. TreadView deploys a unique state of art digital imaging and laser scanning technology for maximum accuracy and efficiency. The product benefits from sophisticated image processing algorithms to assess wheel tread and flange surface condition from acquired multispectral multi- illumination images. There are many additional systems offered by Beena Vision including vehicle mounted for monitoring Permanent Way condition and Handheld systems for workshop and field measurements.