Rail Institute Compiles Report on Production of Light-Weight Bogies

An ambitious plan to double the amount of European freight carried by rail could depend on the development of light-weight bogies produced using stronger steels and innovative manufacturing techniques, according to findings by experts at the University of Huddersfield.

Its Institute of Railway Research is a participant in the project named DYNAFREIGHT, a component of the EU-funded scheme Shift2Rail, which has a total budget of €940 million, which is a joint undertaking under the H2020 Research and Innovation Programme.

Longer Freight Trains

DYNAFREIGHT was launched in late 2016 at a meeting held in Brussels that was attended by the Director of Huddersfield’s IRR, Professor Simon Iwnicki. The stated aim of the project is to seek innovative technical solutions for improved train dynamics and the operation of longer freight trains.

Light-Weight Bogies

Light-Weight Bogies

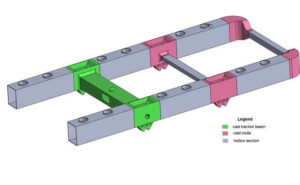

A roster of leading European research institutes and manufacturing companies is taking part. IRR Research Fellow Dr Samuel Hawksbee – a structural engineer – and Visiting Professor Jay Jaiswal – an expert on steels – have taken the lead on a DYNAFREIGHT work package investigating ways to make the bogies of rail vehicles lighter.

Dr Hawksbee, said:

“Potentially, lightweighting has various advantages, such as reducing energy consumption, carbon emissions and damage to the track”

“They provided information on one their bogies and asked what we can do to make it lighter”

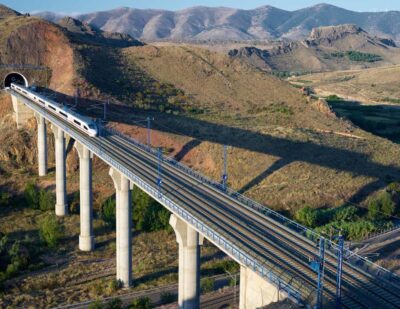

The research at the IRR was carried out in conjunction with the Valencia plant of Swiss-based train manufacturers Stadler.

Innovative Manufacturing Techniques

The focus was placed on the use of higher-strength steels as an alternative to the mild steels normally used for bogie construction. This could result in reduced weight, but it would be vital to develop techniques for improved welding of joints.

Dr Hawksbee added:

“So we are looking not just at what can we do with the steels, but what we can do to manufacturing methods to improve the welds – or to eliminate them completely, by asking if there are different technologies for joining different steel elements”

He added that in order to take advantage of higher strength steels, manufacturing techniques would have to change, and the railway industry could learn from automotive manufacturers, who are well ahead in reducing the weight of components.

But more research is needed, because a rail bogie carries much heavier loads than the chassis of a car, said Dr Hawksbee. He and Professor Jaiswal are now compiling a report on their findings, and it will signal avenues for new directions in research.

Original article © University of Huddersfield.

FOR ALL THE LATEST INFORMATION, NEWS, IMAGES, VIDEOS AND ARTICLES ON ALL ASPECTS OF TRAIN COMPONENTS, PLEASE CLICK HERE.