By Andy Backhouse, Technical Manager, Outokumpu

More than a thousand small and medium-sized railway stations in the UK have no pedestrian footbridges, while many existing bridges are in disrepair and need urgent replacement.

Since the 1960s, bridges have typically been designed individually and built on-site. It’s time-consuming, costly and carbon-intensive. With mounting pressure to make stations more accessible and have a lower environmental footprint, Network Rail is spearheading a project to modernise the rail network’s ageing infrastructure.

The result is the AVA Bridge – a modular, factory-produced footbridge that uses modern manufacturing techniques and new materials like high-strength stainless steel. That means lower carbon emissions, more flexibility, and better aesthetics.

The project aims to change how footbridges are designed, built and maintained throughout the network.

A break from tradition

Until recently, bridge construction in the UK followed a process set over half a century ago. Builders fabricate heavy steel structures on site, weld I-beams together and paint surfaces to protect against corrosion.

Because each station is different, each new footbridge tends to be bespoke. And that means long design timelines, big budgets and the need to constantly close parts of the tracks.

With the AVA Bridge project, Network Rail’s Head of Buildings and Architecture, Anthony Dewar, was looking to turn that process on its head.

His vision was of better, cheaper, less carbon-intensive bridges with short production timelines.

The start of a new era

A full-scale prototype of the AVA Bridge was installed in June 2024 at Sittingbourne, Kent, to give Network Rail and its partners a chance to see how well the modular design would withstand real operating conditions.

The new footbridge uses a “Meccano-like” system where laser-cut and folded stainless steel C-profiles are assembled using pre-loaded bolts, forming robust girder assemblies without relying on welded joints.

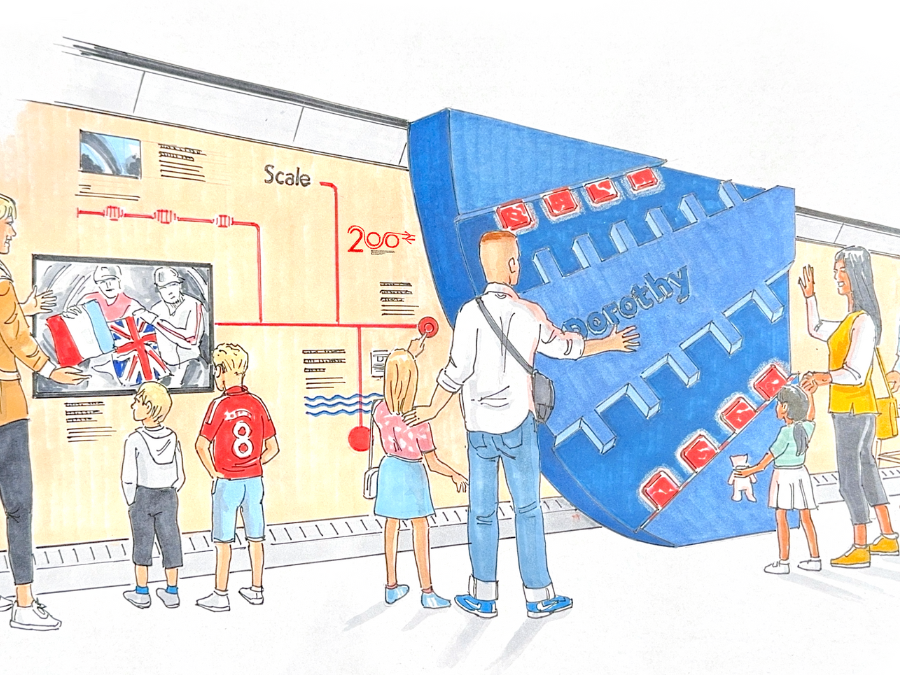

The resulting superstructure offers several big benefits. It lets you customise the height, span and overall layout, meaning it can adjust to fit stations with varying space constraints. The design also gives local communities a footbridge that looks the part: a sleek, stainless steel structure with a bead-blasted finish.

And instead of having to repaint a corroding steel frame regularly, operators now have a durable, corrosion-resistant surface designed to last for decades.

A real group effort

A consortium was involved in the AVA Bridge project, with each party bringing specialised know-how. Lead contractor Walker Construction, construction partner McNealy Brown, the Manufacturing Technology Centre (MTC) and structural experts at Expedition Engineering navigated the technical complexities of turning raw steel plate into a modular frame. Architects at Hawkins\Brown shaped the bridge’s form, and ARX developed the integrated passenger lift.

As part of the team, Outokumpu contributed stainless steel and materials guidance to validate the structural design. With its expertise in duplex stainless steel, Outokumpu resolved questions around grade selection, bend radius and corrosion performance.

The consortium eventually selected the lean duplex grade Forta LDX 2101; an advanced duplex stainless steel that combines high mechanical strength with excellent corrosion resistance. That means the bridge sections are lightweight, uncoated and highly durable.

Why stainless steel?

A key aim in the project was to keep maintenance to a minimum. Traditional carbon steel footbridges need repainting every 30 years, leading to high costs and disruptions to passengers. In contrast, duplex stainless steel is naturally resistant to corrosion, which gives the AVA Bridge a design life of 120 years with little maintenance and no need for painting.

Duplex stainless steel also offers high mechanical strength, so structural engineers can minimise the thickness of many components to make the bridge lighter than its carbon steel equivalent. As a result, it’s possible to downsize foundations and cut the number of truck deliveries. All together, these factors bring a big reduction in the overall carbon footprint.

And the bead-blasted stainless steel finish doesn’t just look good – it’s also hard to vandalise. If a component ever does need replacement, either because of damage or changes to the station layout, a single module can be swapped out without dismantling the entire superstructure.

Modular, plug-and-play assembly

The AVA Bridge concept took its inspiration from modern digital manufacturing techniques. Instead of fully custom designs, engineers rely on standardised 3D plans, each representing a “template” for station footbridges with adjustable features like span length, stair configurations or lift positioning. These templates are uploaded into a manufacturing system that coordinates laser cutting, folding and shipping.

Once the components are precisely produced in factory conditions, they’re bolted together into larger modules like the footbridge span, stair sections and lift enclosure. These arrive ready for installation on pre-prepared concrete pads, and teams assemble them in a fraction of the time needed for traditional on-site construction. The aim is that the entire superstructure can be erected in a single 27-hour window, disrupting trains far less than with the traditional approach.

The bridge’s design also focuses on accessibility. Configurations include wide and narrow versions to fit different spaces, both incorporating new, reliable lifts developed by ARX. The wider versions have through-lift access, meaning they’re easy to use for all passengers, no matter their mobility challenges.

Accessible transport hubs often see higher passenger flow and commercial development – meaning as well as bringing plenty of benefits to Network Rail and train passengers, the bridge also encourages local economic activity.

Taking the idea to the wider world

As a public funding beneficiary, the project has been developed with the added objective of promoting the development of digital manufacturing skills in the UK.

After the end of the project, the AVA Bridge will be an open-source design. In theory, the bridge’s digital designs and manufacturing details will be available to other engineers, architects and manufacturers. The aim is to stimulate a new, localised supply chain for footbridges throughout the UK and potentially beyond.

The open-source approach will help to make stainless steel, fastener technology and modular assembly more widespread, lowering the barriers to adopting new methods.

Bridging the gap between old and new

While the first real-world trial is underway in Sittingbourne, the first official AVA Bridge is scheduled to open to the travelling public at Stowmarket Station, Suffolk, this year. As production ramps up, batch manufacturing and refinement of the design will keep cutting costs and speeding up lead times.

Potential expansions of the AVA concept are already on the table, like including roofs, adjusting designs for longer spans or specifying more corrosion-resistant stainless steel grades (for marine or highly polluted environments). Other industries, like highways and commercial developments, have also shown an interest.

Ultimately, AVA Bridge is a big shift from the traditional, bespoke approach to building railway footbridges. By combining modular components with duplex stainless steel, the project will cut carbon footprints, save on maintenance and develop a manufacturing supply chain that supports local economies and creates jobs.

An independent assessment commissioned by Network Rail gave AVA the highest possible scores for sustainability, passenger experience, safety, maintenance and cost compared with other approved Network Rail footbridges.

And although challenges lie ahead, such as fine-tuning processes for mass production, there’s broad optimism that AVA could become a go-to model for future infrastructure projects.

The AVA Bridge is more than just a structure in the grand scheme of modernising public transport. It’s a testament to what’s possible when structural engineering excellence, forward-thinking manufacturing and sustainable material innovation unite under a shared vision to close the gap between older infrastructure and tomorrow’s public transportation needs.

For more information: https://www.avabridge.com/