Virtek Vision

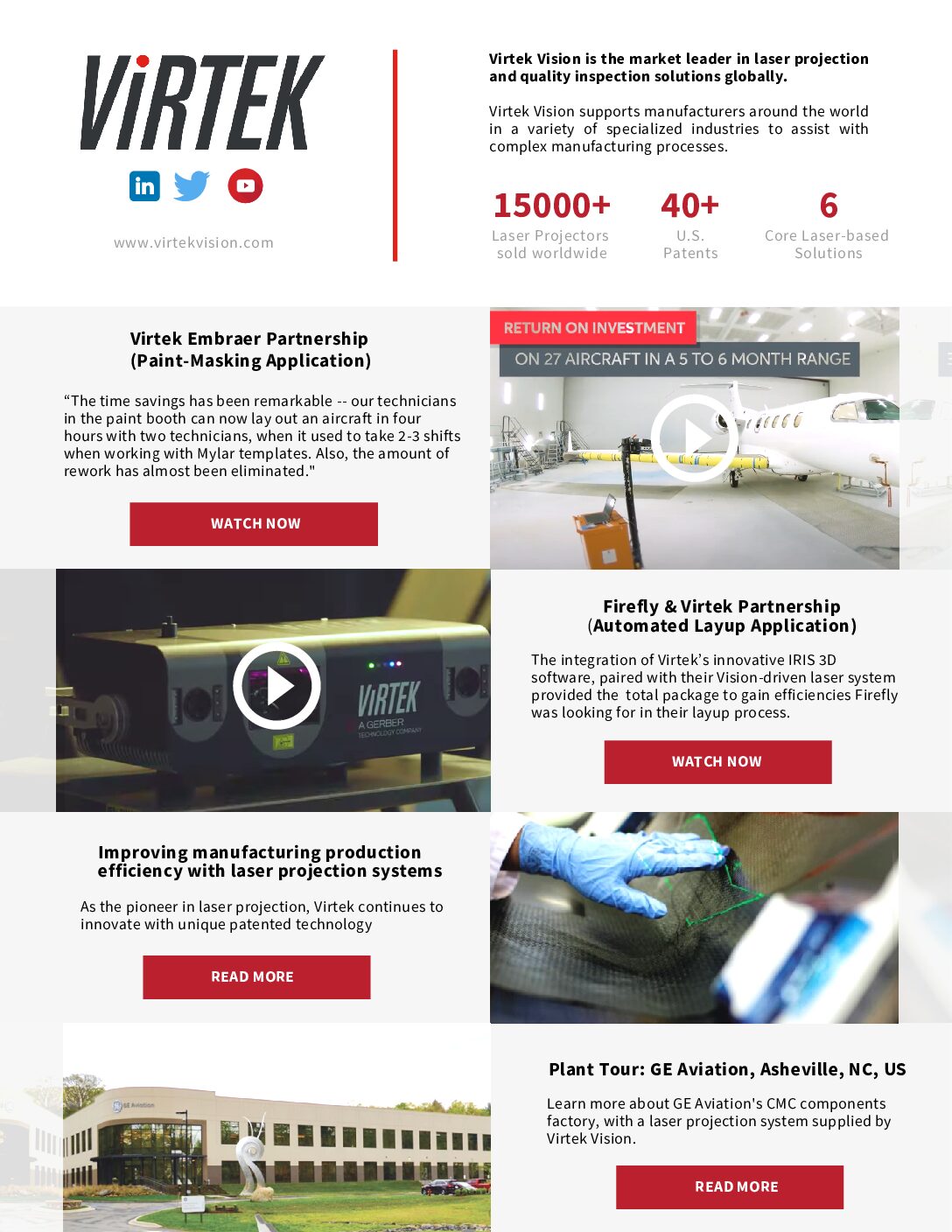

Virtek Iris 3D for Welded Assembly

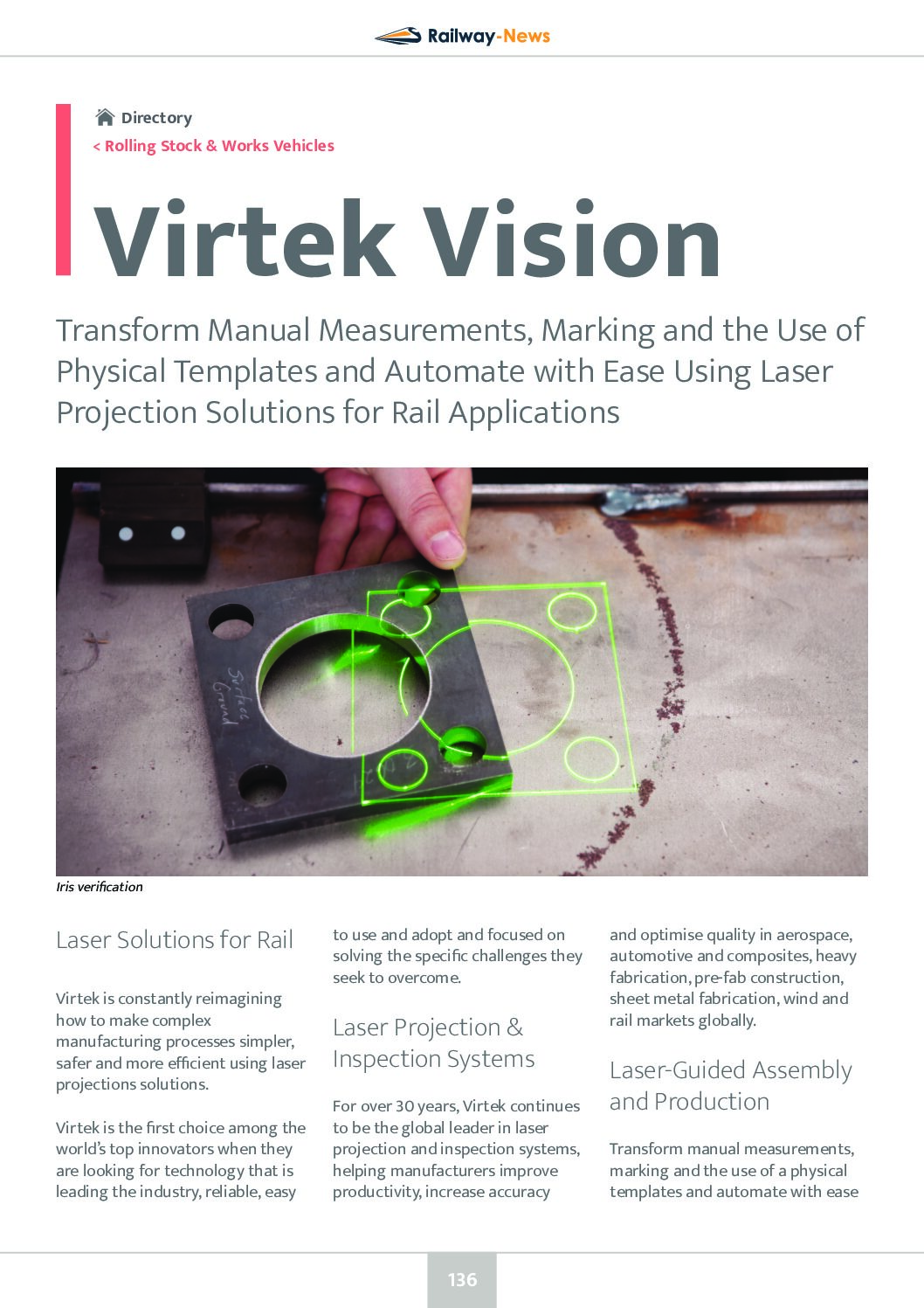

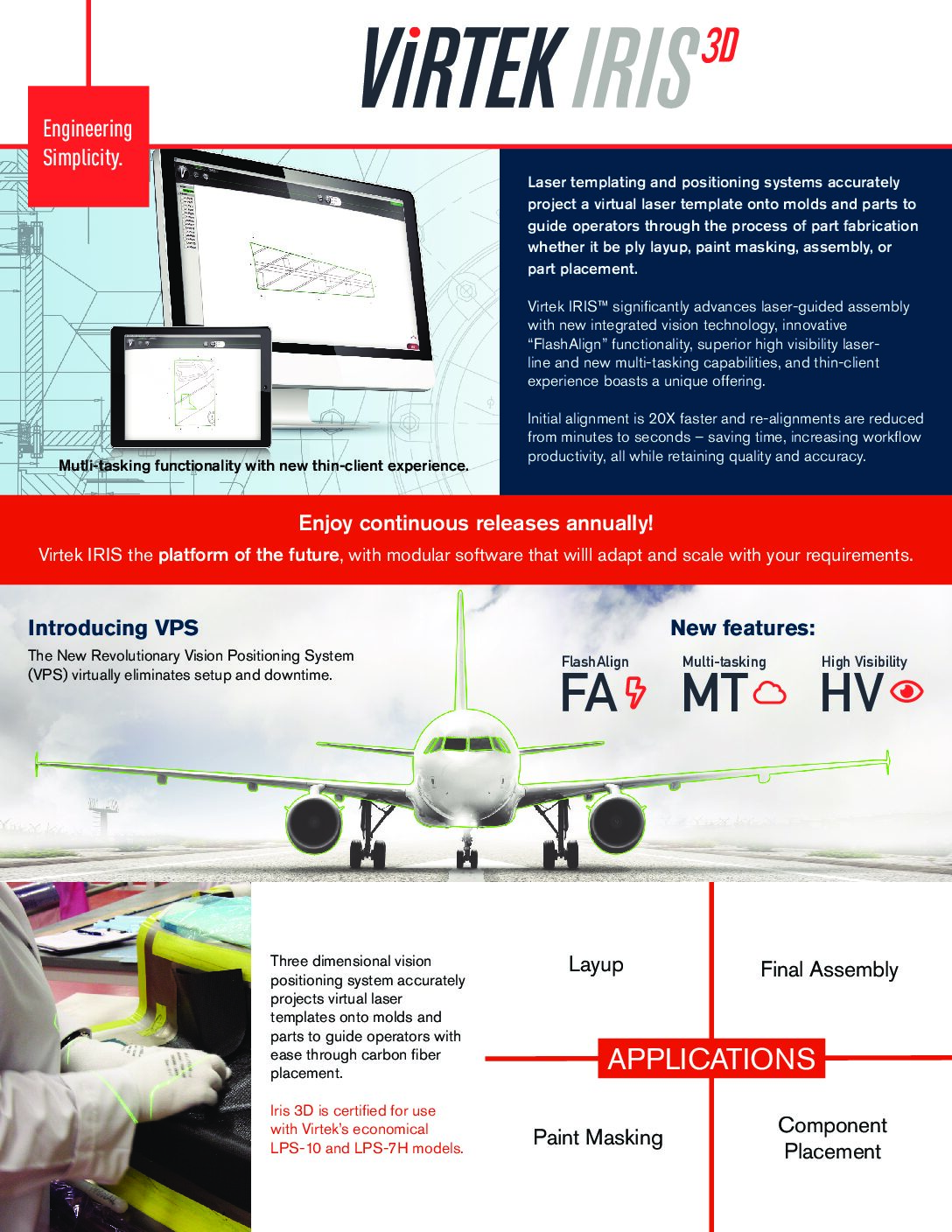

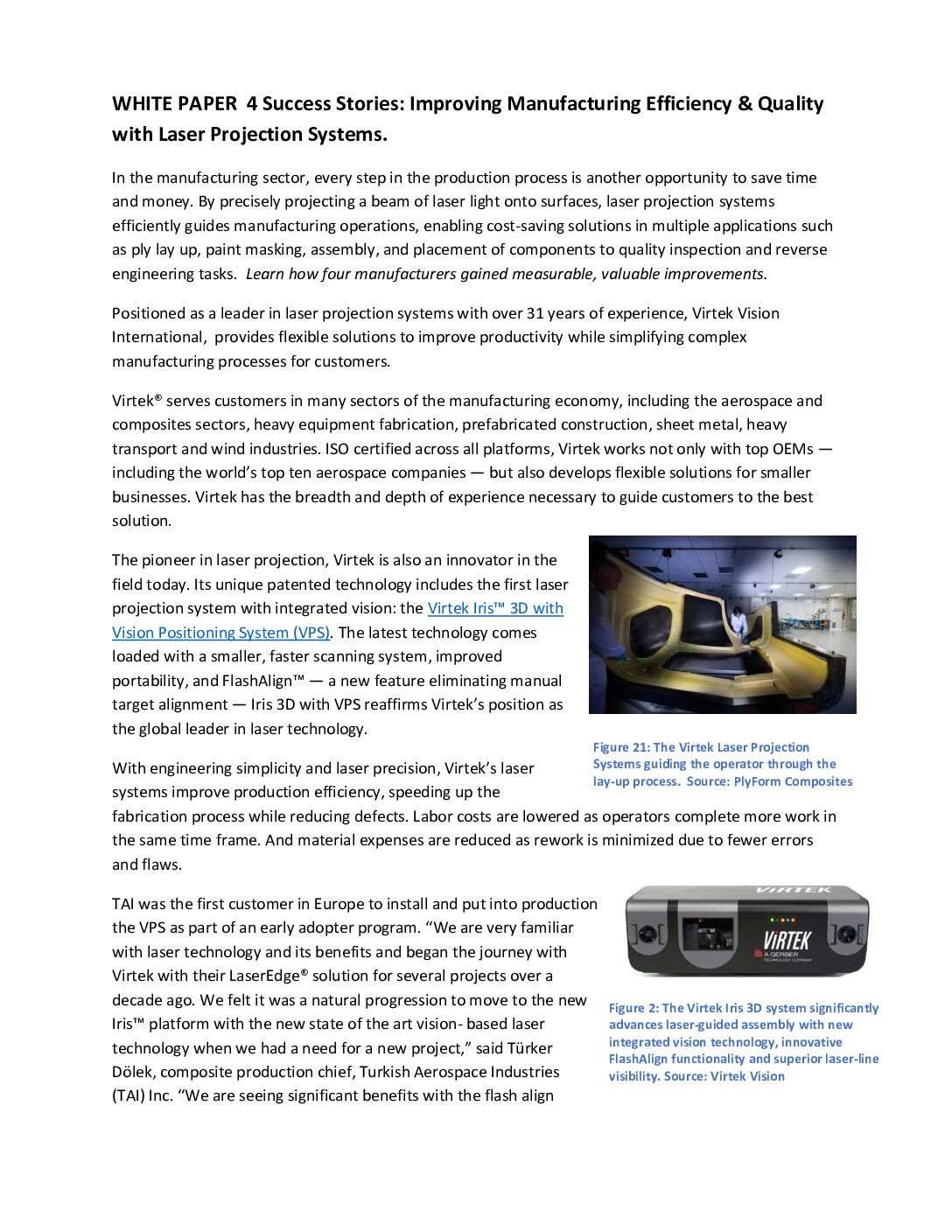

Virtek IrisTM 3D simplifies fitting and accelerates the assembly process by eliminating manual measurement, marking and templates.

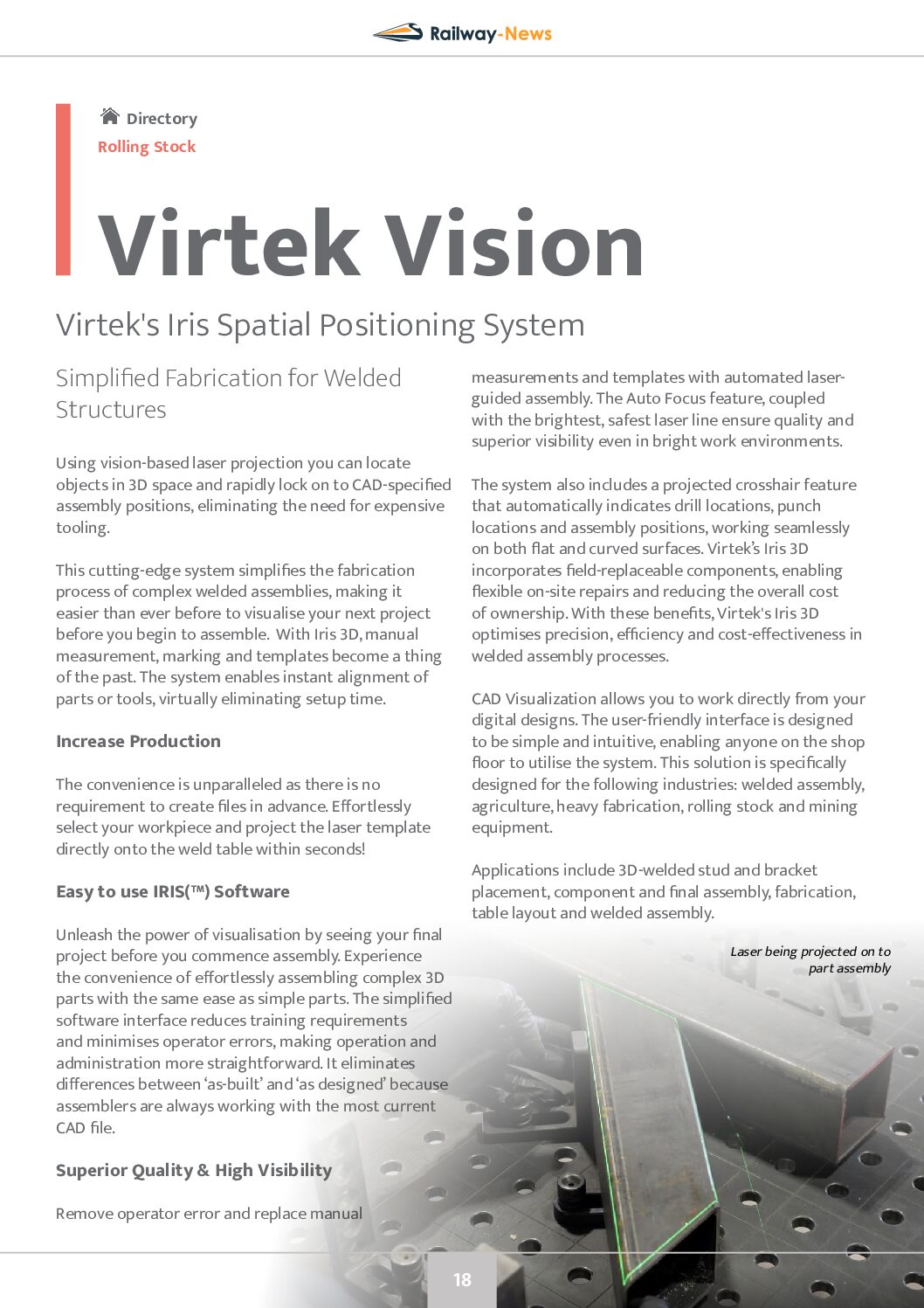

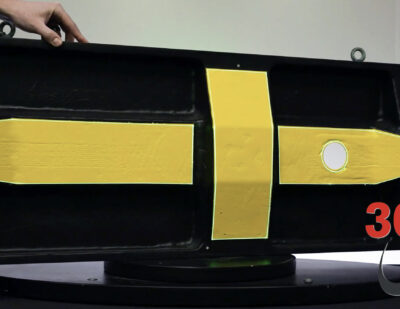

Virtek’s Iris 3D for Welded Assembly applications combines laser projection with 3D vision technology to locate a part in 3D space instantaneously. Light up each step in an assembly with laser accurate lines projected directly onto the part surface.

Iris 3D functionality offers NEW advanced features: CAD Visualization and Pick n Project ( PnP).

Iris 3D works directly from CAD. The interface is simple and intuitive that anyone on the shop floor can use. Operators require little or no training to start producing parts faster and with a higher accuracy.

Complex Welded Assemblies Made Easy

Produce More Faster

- No need to create files in advance, simply pick your work piece and project the laser template at the weld table!

Easy to Use

- Visualize your final project before you even begin assembly.

- Assemble complex 3D parts as easily as simple parts.

- Little to no training required.

Higher Quality

- Remove operator error, and replace manual measurements, templates and training with automated laser-guided assembly.

Markets

Ideal for Jobs Shops and OEMs that serve the following industries:

- Agriculture

- Heavy Fabrication

- Mining Equipment

- Rolling Stock

Applications

- 3D-Welded Stud & Bracket Placement

- Component & Final Assembly

- Fabrication

- Table Layout

- Welded-Assembly

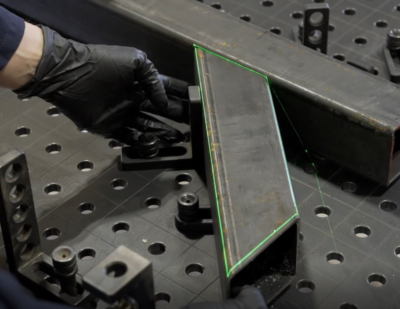

High Visibility Laser

Provides operators with a brighter, safer laser delivering superior visibility even in the brightest work environments.

Features & Benefits

FlashAlignTM: Instant alignment of the part or tool virtually eliminating set up time.

Auto Focus & High Visibility: Auto-Focus fiber connected laser source with optional long range optics. Operators will receive the best laser line quality and superior visibility even in the brightest work environments.

Simplified Software Interface: Reduced training & fewer operator errors, simplified operation and administration.

Projected Cross Hair: Automatically project crosshairs to indicate drill locations, punch locations, assembly positions. Crosshairs work on both flat and curved surfaces.