Plasser & Theurer

URM 700-2

A Multi-Talented Ballast Cleaning Machine for Plain Track and Turnouts

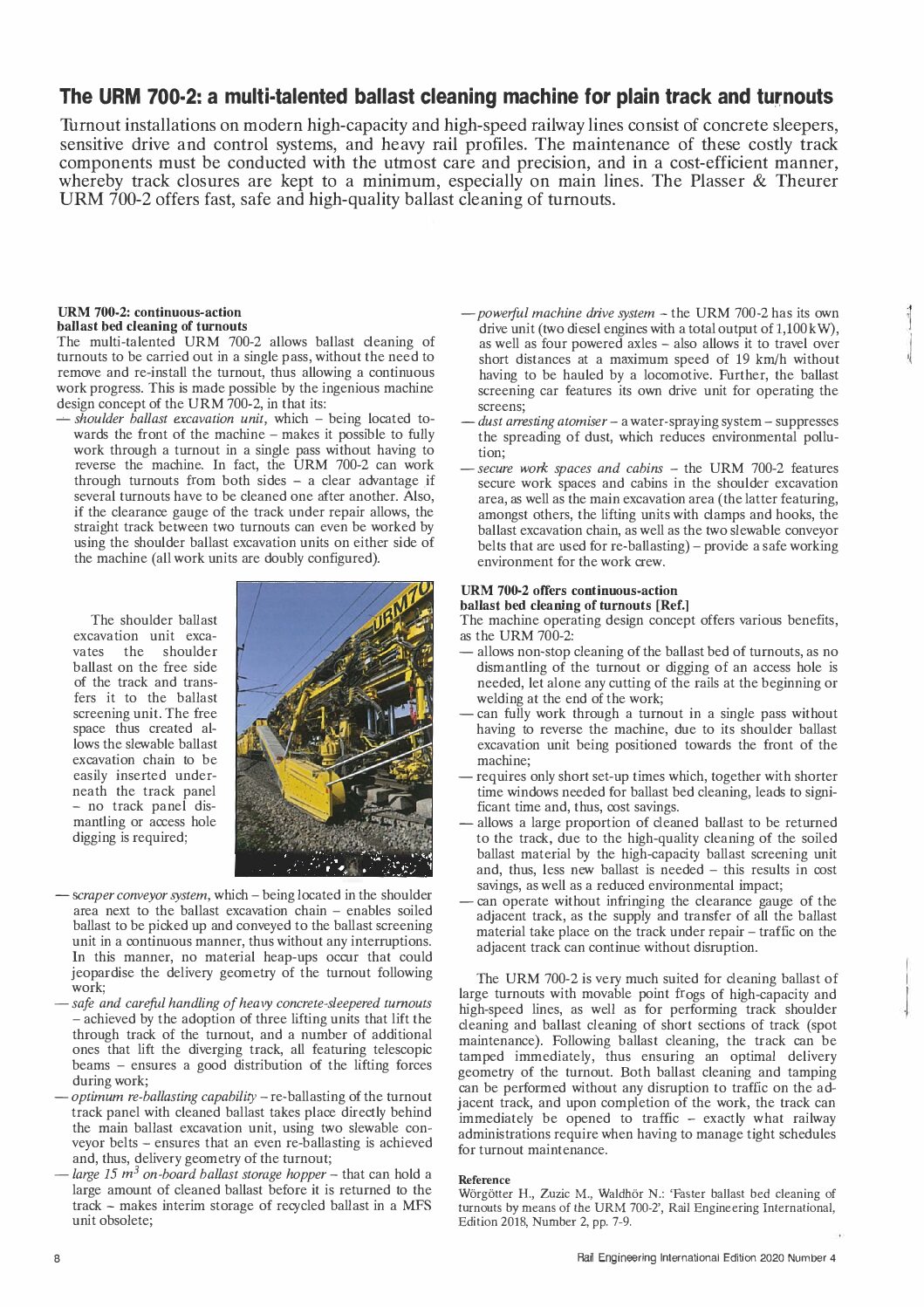

Turnout installations on modern high-capacity and high-speed railway lines consist of concrete sleepers, sensitive drive and control systems, and heavy rail profiles. The maintenance of these costly track components must be conducted with the utmost care and precision, and in a cost-efficient manner, whereby track closures are kept to a minimum, especially on main lines. The Plasser & Theurer URM 700-2 offers fast, safe and high-quality ballast cleaning of turnouts.

The URM 700-2 is very much suited for cleaning ballast of large turnouts with movable point frogs of high-capacity and high-speed lines, as well as for performing track shoulder cleaning and ballast cleaning of short sections of track (spot maintenance). Following ballast cleaning, the track can be tamped immediately, thus ensuring an optimal delivery geometry of the turnout. Both ballast cleaning and tamping can be performed without any disruption to traffic on the adjacent track, and upon completion of the work, the track can immediately be opened to traffic – exactly what railway administrations require when having to manage tight schedules for turnout maintenance.