Pandrol

Under Sleeper Pads in Heavy Haul: Extending the Life of the Railway

This article first appeared in the Railway-News magazine, Issue 3 2022.

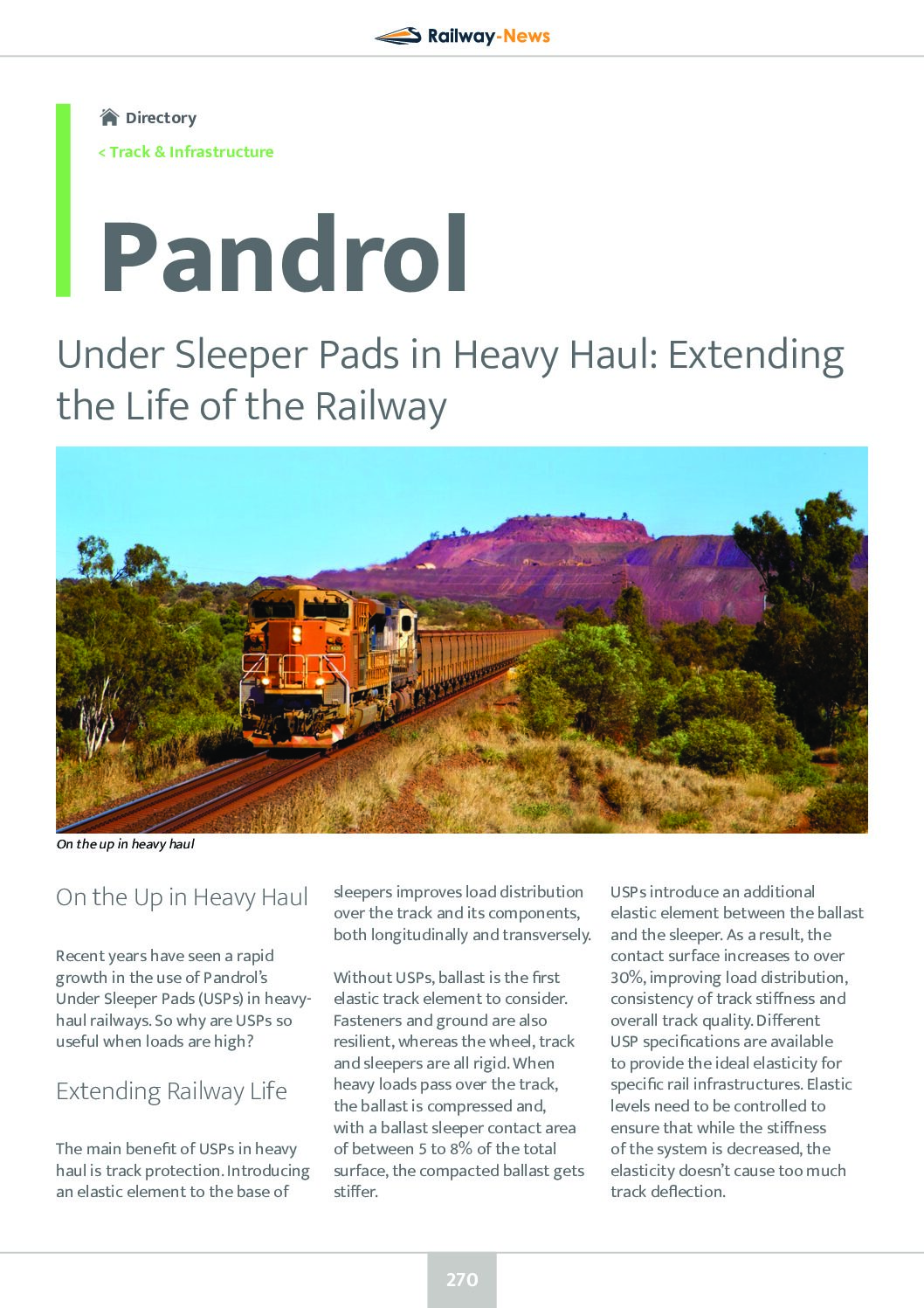

On the Up in Heavy Haul

Recent years have seen a rapid growth in the use of Pandrol’s Under Sleeper Pads (USPs) in heavy- haul railways. So why are USPs so useful when loads are high?

Extending Railway Life

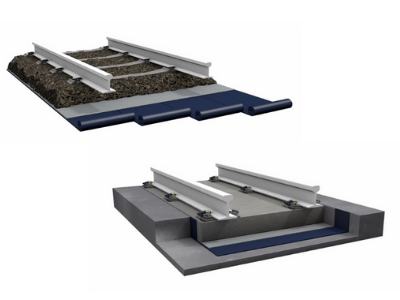

The main benefit of USPs in heavy haul is track protection. Introducing an elastic element to the base of sleepers improves load distribution over the track and its components, both longitudinally and transversely.

Without USPs, ballast is the first elastic track element to consider. Fasteners and ground are also resilient, whereas the wheel, track and sleepers are all rigid. When heavy loads pass over the track, the ballast is compressed and, with a ballast sleeper contact area of between 5 to 8% of the total surface, the compacted ballast gets stiffer.

USPs introduce an additional elastic element between the ballast and the sleeper. As a result, the contact surface increases to over 30%, improving load distribution, consistency of track stiffness and overall track quality. Different USP specifications are available to provide the ideal elasticity for specific rail infrastructures. Elastic levels need to be controlled to ensure that while the stiffness of the system is decreased, the elasticity doesn’t cause too much track deflection.

In the long term, maintenance costs are reduced and the life of the track superstructure is extended. There is less rail corrugation (especially on curves). The frequency of levelling, lining and tamping (LLT) can be reduced by a minimum factor of two.

On Track to Carbon Neutral (SRS Product Range)

Pandrol Receives World First CO2-Neutral Label for Under Sleeper Pad

Global rail fastening specialist Pandrol has underlined its commitment to working collaboratively towards global carbon neutrality, supporting certified climate projects across the world to reduce its total carbon impact.