ADLINK Technology

Transforming the Rail Industry with AI

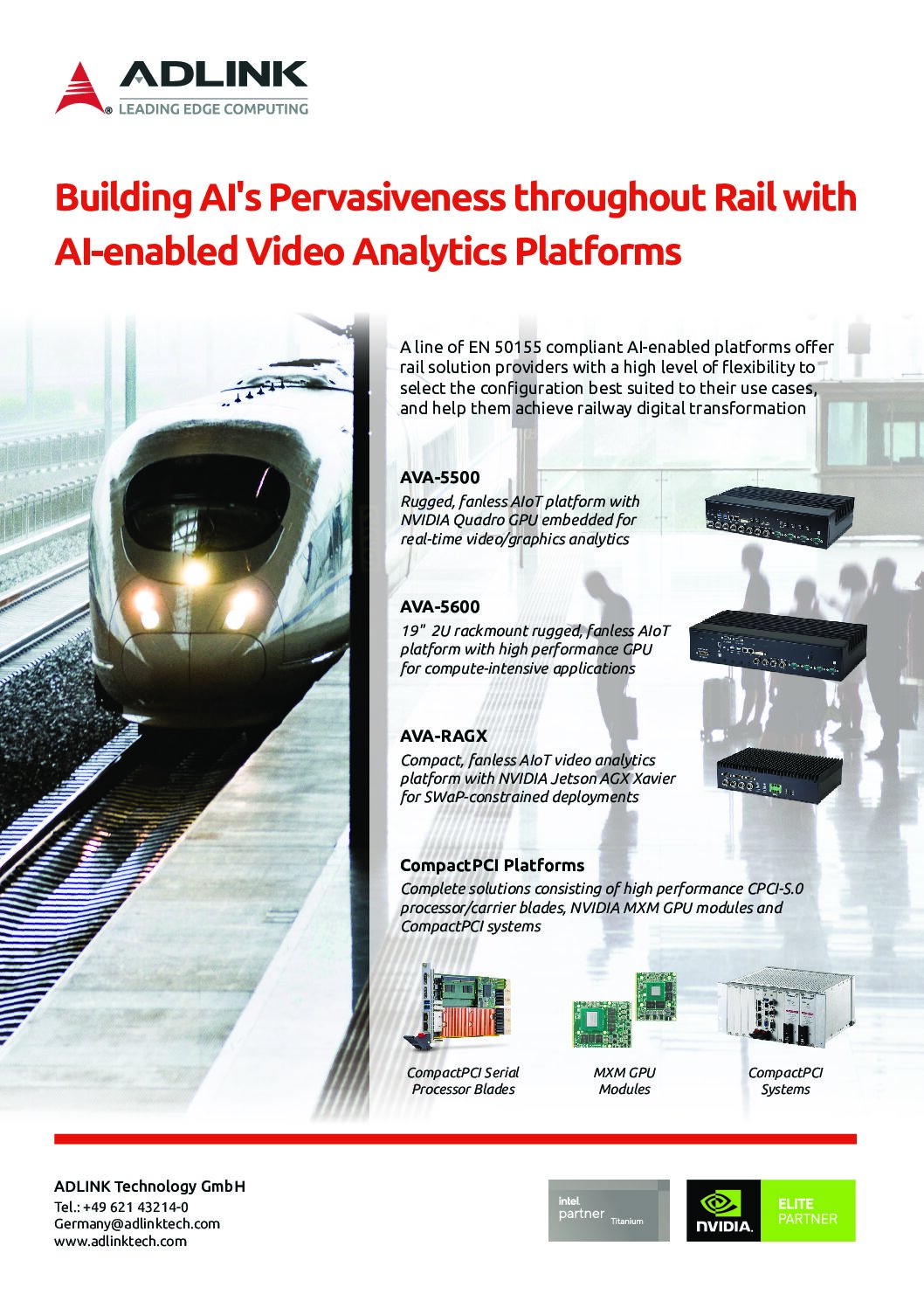

AI accelerates railway digitalization to improve safety and operational efficiency. AI’s pervasiveness helps the rail industry create new business opportunities, and deliver smarter and safer customer services.

Artificial intelligence (AI) continues to improve automation efficiency and accuracy in every industry. While analyzing and interacting with data in real time, AI can offload physical and logical work from humans while converting the work of many into streamlined functions for a few. This is particularly evident in today’s AI- powered systems and applications as they continue to boost productivity and safety across many sectors, including transportation.

The rail industry has long needed modernization, and that need is quickly becoming critical. Consider the function of autonomous operation, which is made possible through AI. A 2020 study titled “Cost Analysis of Driverless Truck Operations” found that a balanced analysis (between optimistic and pessimistic forecasts) of driverless trucks determined cost savings of 29% to 45% compared to manually-operated trucks. One source noted a 15% to 20% drop in total cost of ownership for driverless trucks. Such cost advantages could dramatically upset the cost dynamics of cargo transportation, giving road-based solutions a significant advantage over rail. The article also states, “Having the flexibility to travel by [autonomous] car without owning one could change the riding habits of rail passengers in sparsely populated areas, affecting large swaths of [rail] systems.”

However, the Association of American Railroads observes that technological modernization can benefit rail in many ways, including:

- Fuel management: Sensor data tracking factors from track grade to wind speed to train weight can inform real-time calculations to optimize fuel use and increase rail’s cost advantages over road-based shipping alternatives.

- Train control: Visual systems analysis is only one of many input systems that can help automate safety systems and help slow or stop a train without the need for potentially fallible human involvement.

- Wayside-based preventative monitoring: Sensors near tracks can observe passing trains and help watch for potentially dangerous or costly conditions, such as component wear.

- Train-mounted monitoring: Cameras installed on or under trains can gather data about rail conditions, such as curvature and grade, providing live information for analysis that can inform safety and maintenance decisions.