Roediger Vacuum

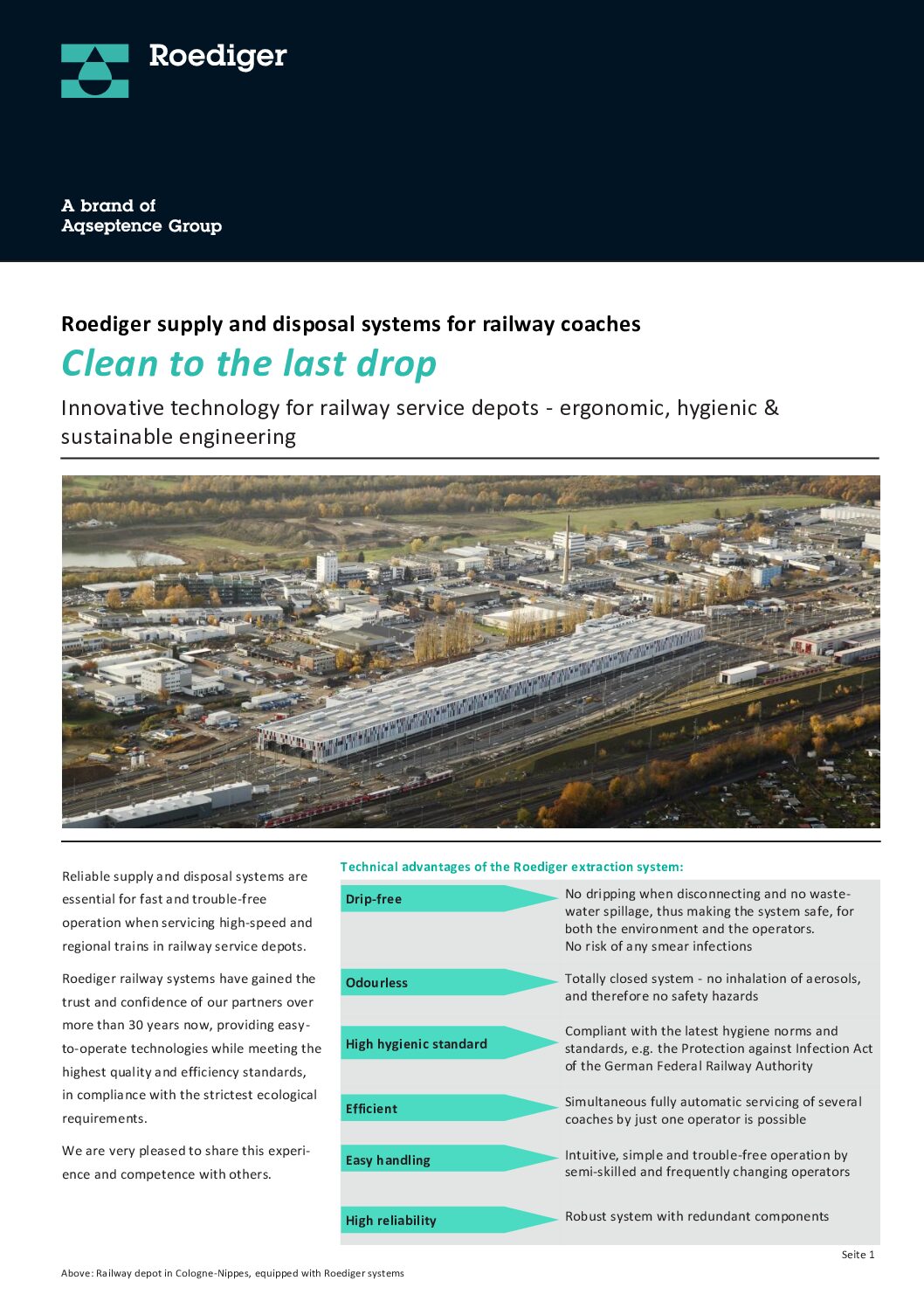

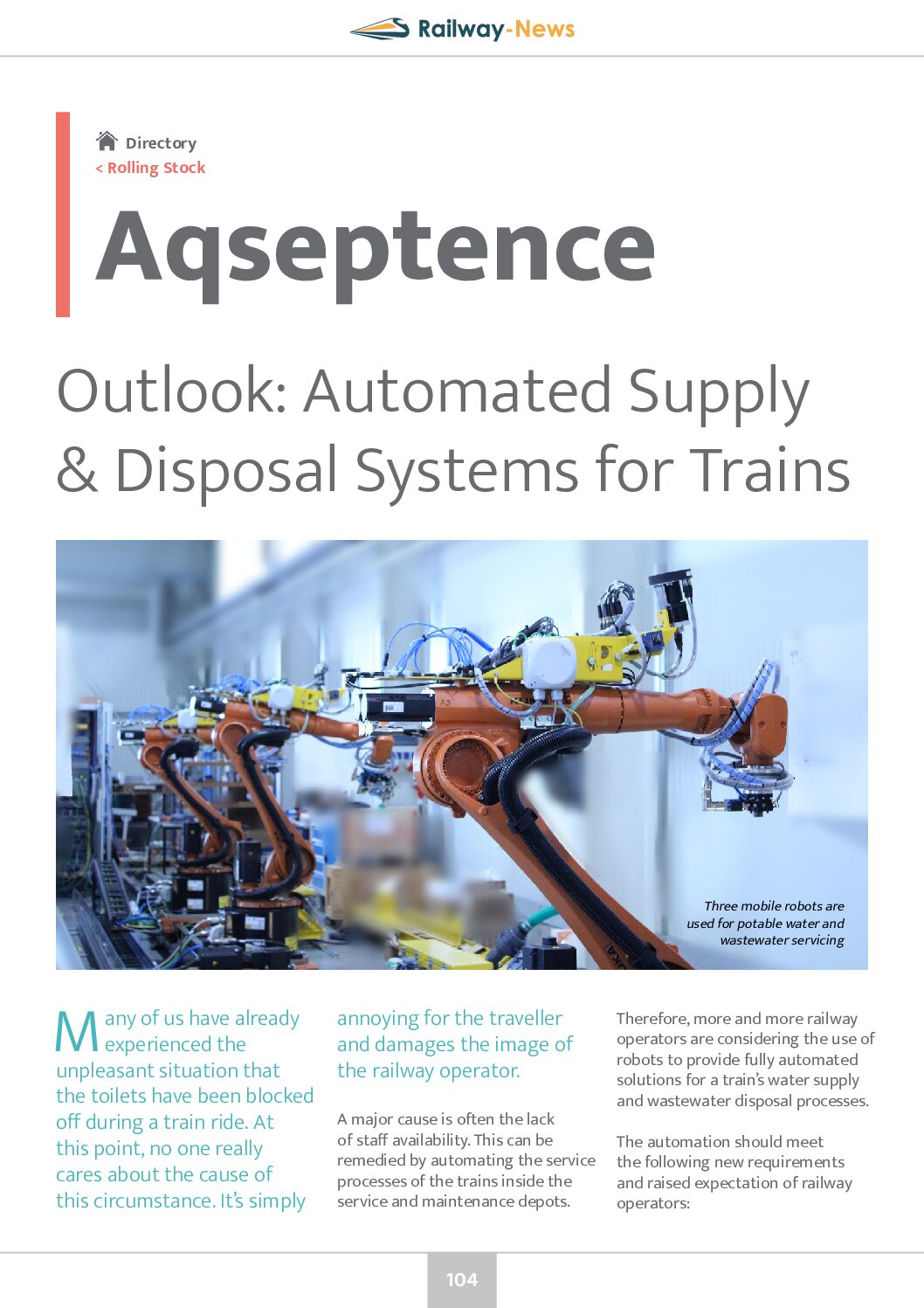

Reliable supply and disposal systems are essential for fast and trouble-free operation when servicing high-speed and regional trains in railway service depots.

Roediger® railway systems have gained the trust and confidence of our partners over more than 30 years now, providing easy- to-operate technologies while meeting the highest quality and efficiency standards, in compliance with the strictest ecological requirements.

We are very pleased to share this experience and competence with others.

Roediger® Vacuum Station – Mini, Compact or Individual

In terms of operational reliability and ease of maintenance, central vacuum stations are the preferred choice for railway service depots.

The size and capacity of Roediger® vacuum stations is dependent upon the specific requirements of each railway service depot. The large Roediger® product portfolio provides for a wide range of innovative, cost-effective and customer-oriented solutions – from economic mini or compact stations, to large customized plants serving several tracks, enabling numerous extraction operations along a train to take place simultaneously.

Patented Roediger® Disposal System

The combination of Roediger® train valves and extraction pistols allows for simultaneous automatic servicing of various coaches by just one operator.

As the extraction pistol valve closes automatically after the disposal process, the operator can trigger the extraction of several wastewater tanks simultaneously, without any delay.

Roediger® Extraction Pistol – New Generation, Type UP7

The new generation of extraction pistols display, once again, the top quality and high efficiency that Roediger® is so well-known for.

These new valves are actually now less costly, with a lower weight and a more compact design, as compared to the previous series.

Optionally, the extraction pistols may be supplied with integrated remote controls for the reeling in and out of the hoses of the motorized hose-drum systems.

Roediger® Train Valve – New Generation, Type 183-40

The new automatic train valves can now also be supplied at lower prices!

Brand-new, modern production methods enable our clients to benefit from a reduced price and a more compact design, with lower weight.

The valves are flexibly integrated, compatible with the assembly situation inside the train, and can be operated in all climatic zones (also due to an internal heating feature).

In addition, the maintenance interval of the valves is now significantly extended.