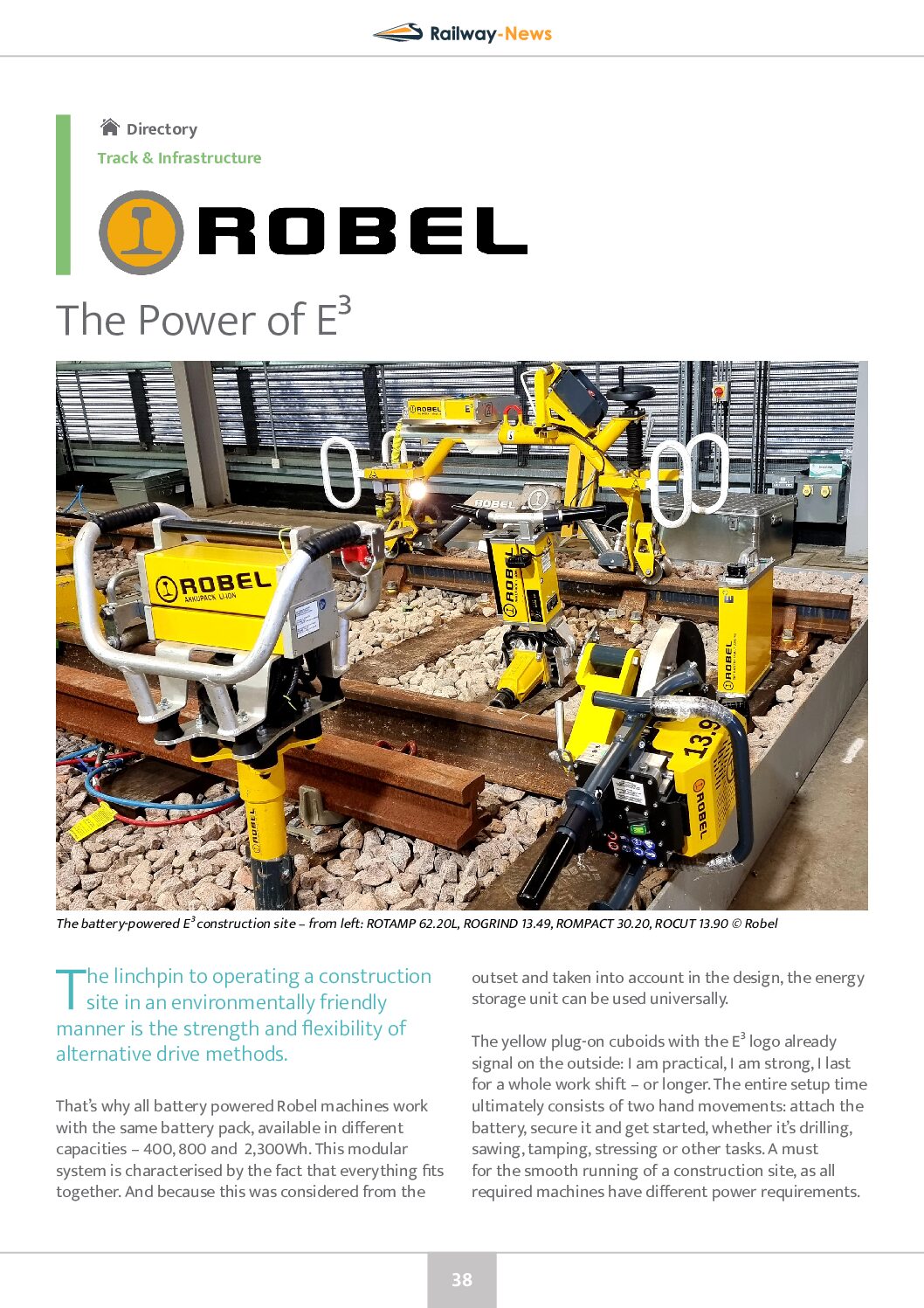

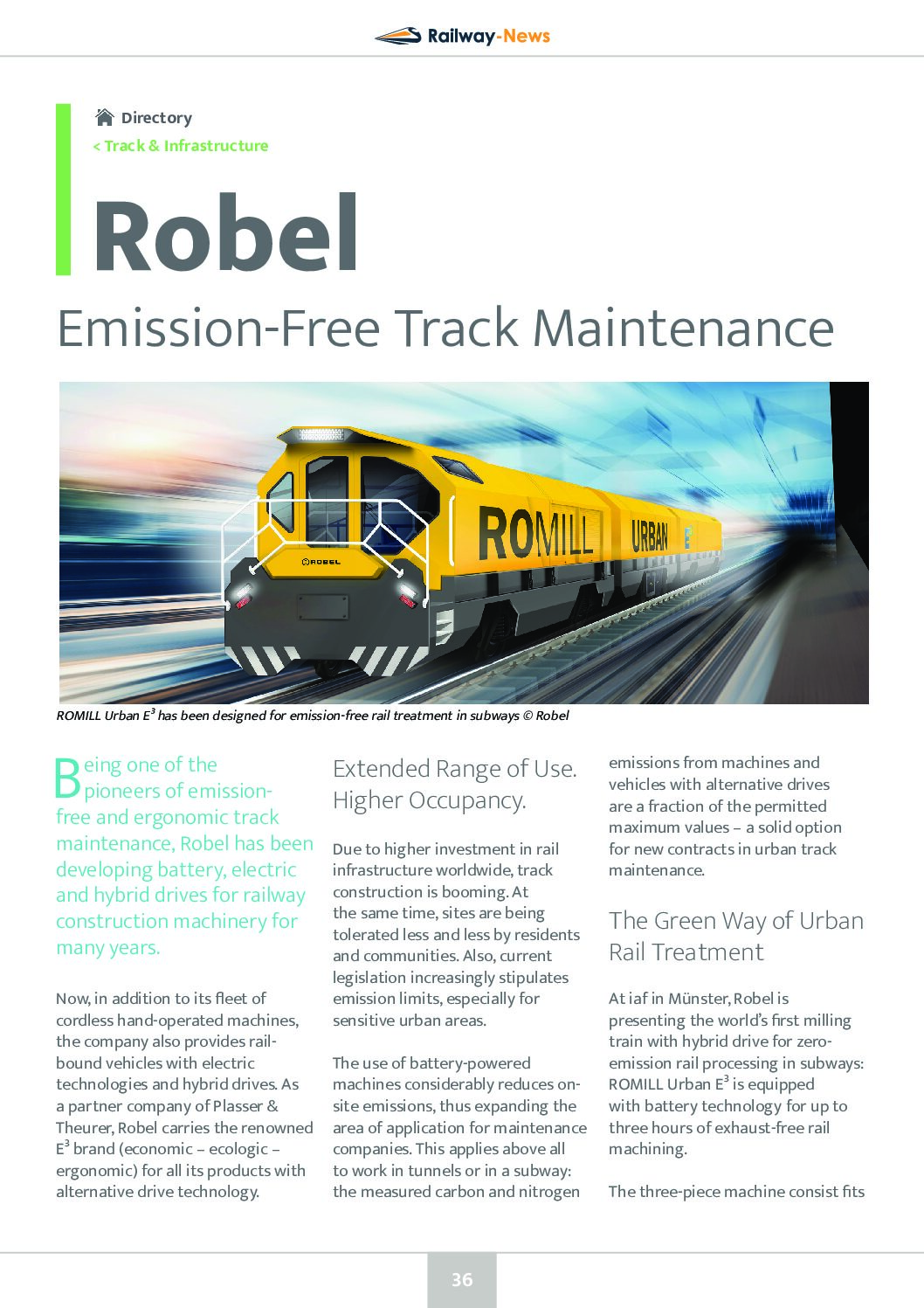

ROBEL

A Clean Solution – New Methods of Railway Infrastructure Cleaning

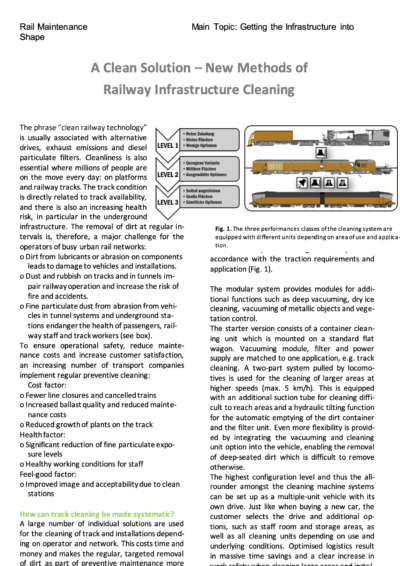

The phrase “clean railway technology” is usually associated with alternative drives, exhaust emissions and diesel particulate filters. Cleanliness is also essential where millions of people are on the move every day: on platforms and railway tracks. The track condition is directly related to track availability, and there is also an increasing health risk, in particular in the underground infrastructure. The removal of dirt at regular intervals is, therefore, a major challenge for the operators of busy urban rail networks:

- Dirt from lubricants or abrasion on components leads to damage to vehicles and installations.

- Dust and rubbish on tracks and in tunnels impair railway operation and increase the risk of fire and accidents.

- Fine particulate dust from abrasion from vehicles in tunnel systems and underground stations endanger the health of passengers, rail- way staff and track workers.

To ensure operational safety, reduce maintenance costs and increase customer satisfaction, an increasing number of transport companies implement regular preventive cleaning:

- Cost factor:

- Fewer line closures and cancelled trains

- Increased ballast quality and reduced maintenance costs

- Reduced growth of plants on the track

- Health factor:

- Significant reduction of fine particulate exposure levels

- Healthy working conditions for staff

- Feel-good factor:

- Improved image and acceptability due to clean stations

Contents

- How can track cleaning be made systematic?

- Fast cleaning without water and chemicals: dry ice cleaning

- A clean track as a win-win solution

- Controversial topic: fine particulates

About ROBEL

Since 1901 ROBEL has developed, manufactured and supplied track construction machines with a claim for safety and economic efficiency. This drives around 500 employees at the ROBEL premises in Freilassing, Germany, to create powerful machines and systems and deliver good service for the construction and maintenance of railway infrastructure systems all over the world.