ROBEL

From Old to New: Retrofits for Track Maintenance Vehicles

Railway construction companies are short of time. Construction windows are getting smaller and smaller, the required process speed is increasing. For a machine fleet this means more or less round the clock availability. This permanent availability can only be ensured with regular maintenance and overhauls or scheduled overhauls and expansion of the vehicle fleet.

The operating company is facing the challenge to maintain or increase the productive efficiency of its track construction machines and to keep the downtimes required as low as possible at the same time. Successful fleet management has to determine the optimum time and scope of maintenance. In a next step, the company needs to decide for which services it has in-house capacity and at what point it is economically more efficient to outsource the work to a service partner.

This article illustrates the range of services and the benefits of a so-called “retrofit” (complete overhaul) of construction machines, provides information about the required resources, about decision criteria and strategies.

Contents

- Overhaul or new purchase?

- Overview of the benefits of a retrofit

- From revision to retrofit: exceeding legal requirements

- The quotation as a decision maker

- The manufacturer as a service partner

- Retrofit – (almost) everything is possible

- It’s all a matter of time

- From old to new – retrofit in detail

- Pushing the limits

- Summary

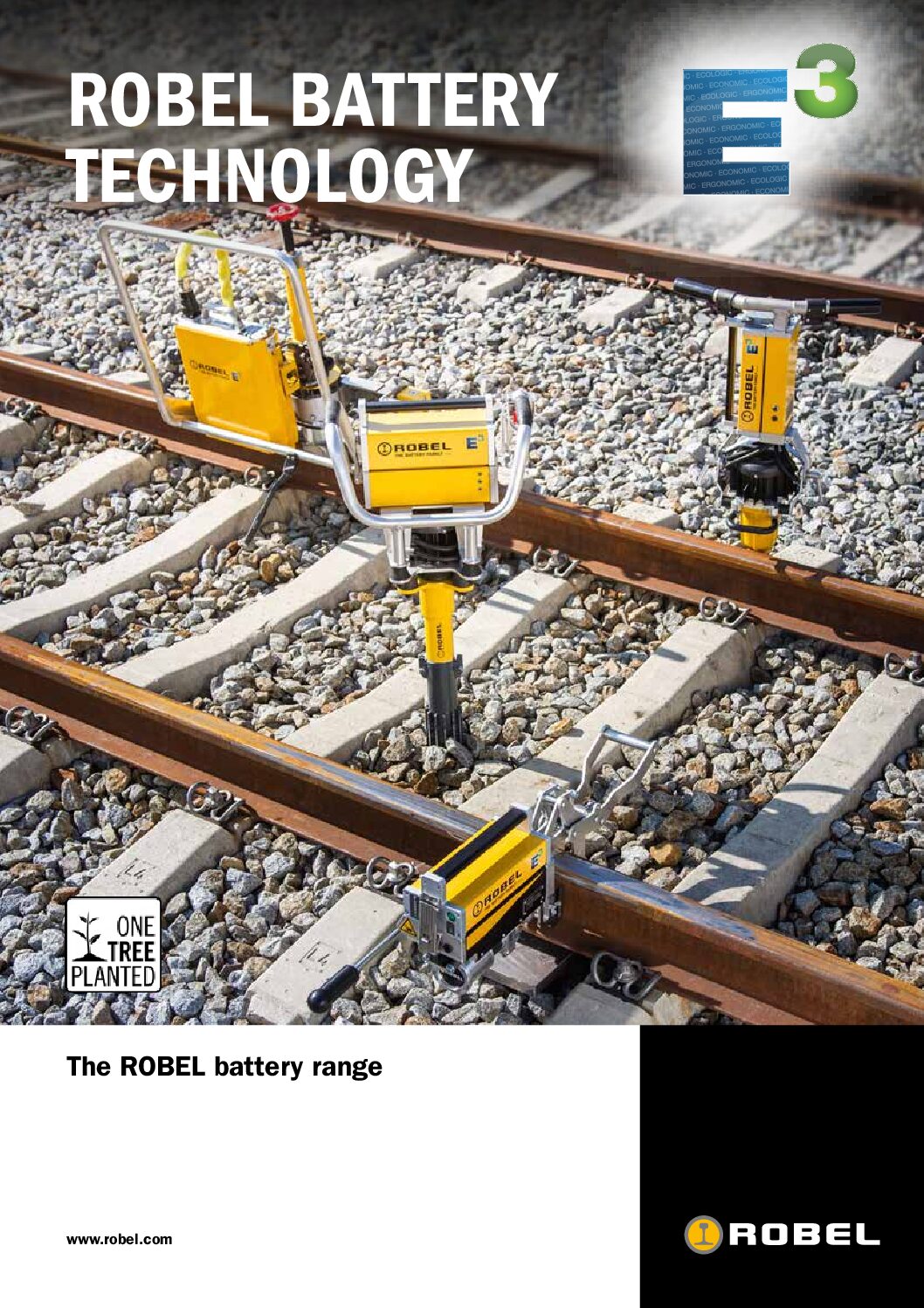

About ROBEL

Since 1901 ROBEL has developed, manufactured and supplied track construction machines with a claim for safety and economic efficiency. This drives around 500 employees at the ROBEL premises in Freilassing, Germany, to create powerful machines and systems and deliver good service for the construction and maintenance of railway infrastructure systems all over the world.