ROBEL

DB Guideline as the Benchmark for New Wrenching Method

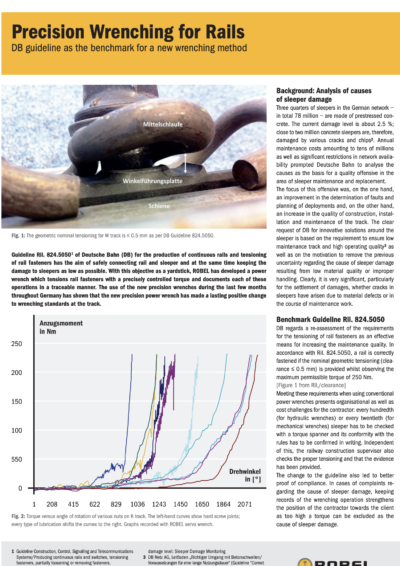

Guideline Ril. 824.50501 of Deutsche Bahn (DB) for the production of continuous rails and tensioning of rail fasteners has the aim of safely connecting rail and sleeper and at the same time keeping the damage to sleepers as low as possible. With this objective as a yardstick, ROBEL has developed a power wrench which tensions rail fasteners with a precisely controlled torque and documents each of these operations in a traceable manner. The use of the new precision wrenches during the last few months throughout Germany has shown that the new precision power wrench has made a lasting positive change to wrenching standards at the track.

Precision Wrenching for Rails in Germany

As the new guideline has come into force, the landscape has changed. The prescribed checks and documentation of each screw joint as a rule means additional staff and time for the contractor. This results in costs which do not arise when using the fully hydraulic precision wrench. Furthermore, the new wrenching method leads to savings in areas which have been a fixed part of all wrenching work on the track up to now, such as external calibration, set-up costs and continuous reworking.

The 30.73 PSM precision wrench provided its first proof of performance on the Kassel-Hanover high-speed line in April 2016. After nine months of widespread field operations, the potential of precise wrenching for rails has become apparent.