Zonegreen

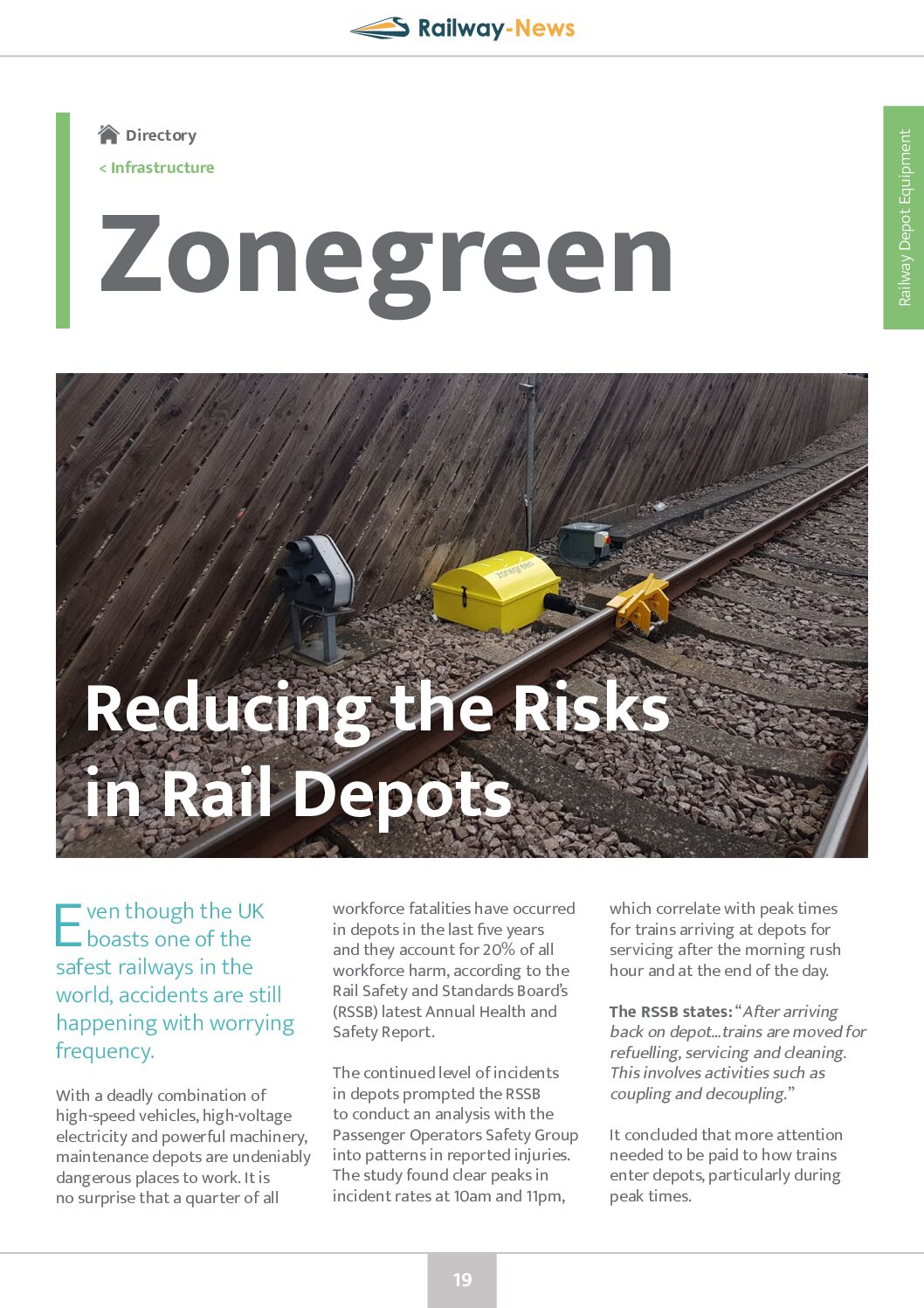

Reducing the Risks in Rail Depots

- This article first appeared in the Railway-News magazine Issue 3 2021.

Even though the UK boasts one of the safest railways in the world, accidents are still happening with worrying frequency.

With a deadly combination of high-speed vehicles, high-voltage electricity and powerful machinery, maintenance depots are undeniably dangerous places to work. It is no surprise that a quarter of all workforce fatalities have occurred in depots in the last five years and they account for 20% of all workforce harm, according to the Rail Safety and Standards Board’s (RSSB) latest Annual Health and Safety Report.

The continued level of incidents in depots prompted the RSSB to conduct an analysis with the Passenger Operators Safety Group into patterns in reported injuries. The study found clear peaks in incident rates at 10am and 11pm, which correlate with peak times for trains arriving at depots for servicing after the morning rush hour and at the end of the day.

The RSSB states: “After arriving back on depot…trains are moved for refuelling, servicing and cleaning. This involves activities such as coupling and decoupling.”

It concluded that more attention needed to be paid to how trains enter depots, particularly during peak times.

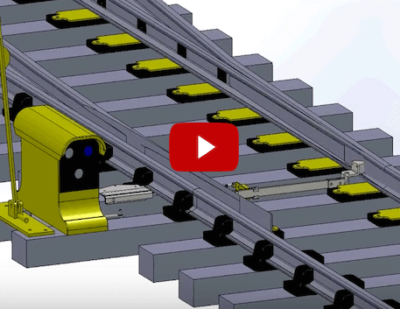

Protecting Our Depot Workers

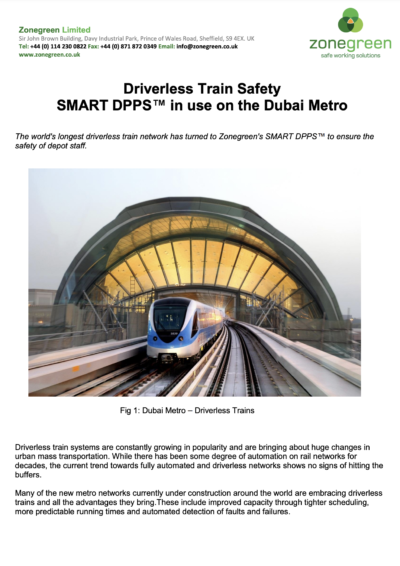

If we are to mitigate accidents and injuries in rail depots, it is clear the movement of vehicles needs to be made safer. The easiest way to do this is to remove the margin for human error.