Rajant Corporation

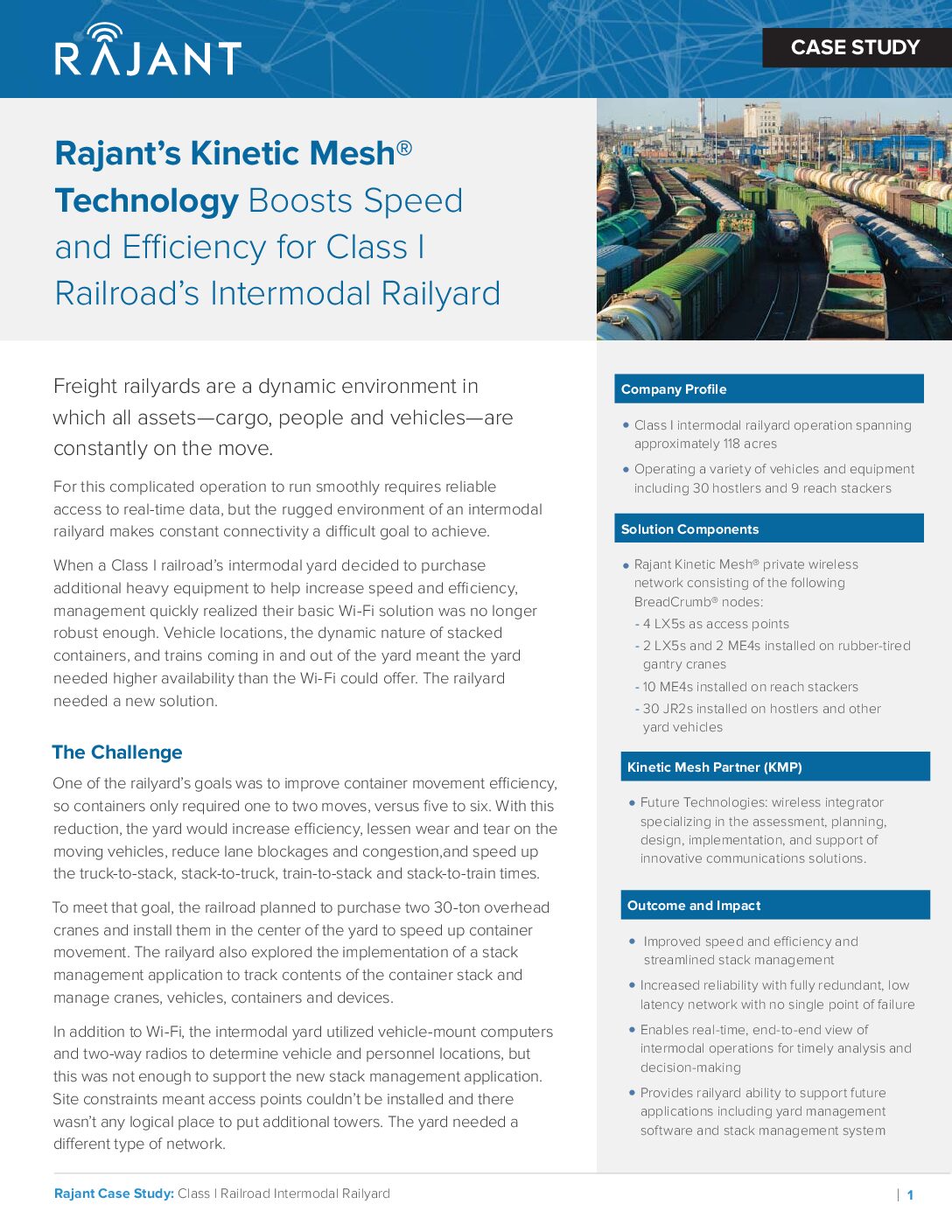

Rajant’s Kinetic Mesh® Technology Boosts Speed and Efficiency for Class I Railroad’s Intermodal Railyard

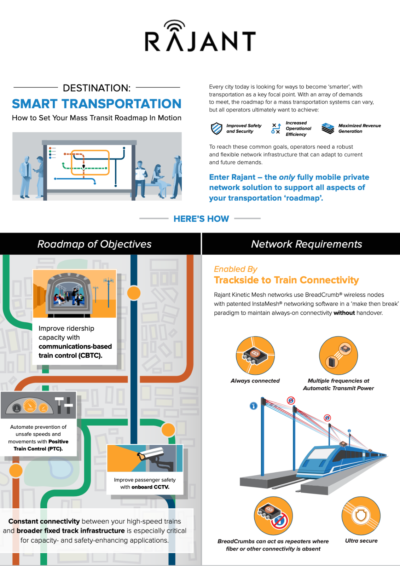

Freight railyards are a dynamic environment in which all assets—cargo, people and vehicles—are constantly on the move. For this complicated operation to run smoothly, a network with reliable access to real-time data is required, but the rugged environment of an intermodal railyard makes constant connectivity a difficult goal to achieve.

When a Class I railroad’s intermodal yard decided to purchase additional heavy equipment to help increase speed and efficiency, management quickly realized their basic Wi-Fi solution was no longer robust enough. Vehicle locations, the dynamic nature of stacked containers, and trains coming in and out of the yard meant the yard needed higher availability than the Wi-Fi could offer. The railyard needed a new solution.

The Challenge

One of the railyard’s goals was to improve container movement efficiency, so containers only required one to two moves, versus five to six. With this reduction, the yard would increase efficiency, lessen wear and tear on the moving vehicles, reduce lane blockages and congestion, and speed up the truck-to-stack, stack-to-truck, train-to-stack and stack-to-train times.

To meet that goal, the railroad planned to purchase two 30-ton overhead cranes and install them in the center of the yard to speed up container movement. The railyard also explored the implementation of a stack management application to track contents of the container stack and manage cranes, vehicles, containers and devices.