NSH Group & NSH USA

Railway Wheelset Maintenance: NSH Group Delivers Continuous Improvement

This article first appeared in the Railway-News magazine, Issue 3 2022.

The NSH Group (Niles-Simmons-Hegenscheidt) and its North American subsidiary NSH USA Corporation (Albany, New York and Sterling Heights, Michigan) have a long history of supporting transit and freight railway maintenance facilities worldwide.

This longevity is based in part on a dedication to continuous improvement of wheelset maintenance machines and practices.

The Stanray® Wheel Truing Machines have been the standard for freight and transit railway wheel reprofiling throughout North America for decades. The machines utilise milling machining technology (known as ‘wheel truing’) where the work piece (in this case, the wheelset) rotates slowly while the cutting tool with multiple cutting inserts rotates rapidly. This wheel reprofiling technology differs from a lathe (known as ‘turning’), where the work piece rotates rapidly, and the single point cutting tool is stationary. Both technologies reprofile the wheel and remove wear and defects to return the wheel profile back to the optimal shape. However, for customers with moderate or extreme wheel wear, wheel truing (milling) is the ideal solution due to the milling cutter’s efficient material removal properties.

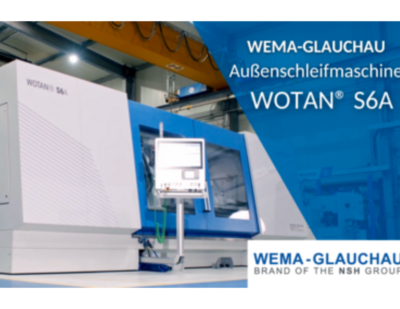

NSH USA recently updated the Stanray product line with the new M-Series Wheel Truing Machines. While still employing the same milling machining technology, the new machines include innovations that were not possible when the Stanray was introduced in 1949.

They now feature integrated measurement for more efficient machining as well as better access to asset data. The system’s automated machining and measuring cycles mean less chance for operator error and increased safety and efficiency. And with the new patent-pending centreless wheelset clamping, less time is spent accessing wheelset axle centres – in fact, wheel truing can take place on fully mounted wheelsets as well as vehicles that were not accessible before. The new machines can be installed on the facility’s floor as an Above-Floor M1 or in a pit as an Underfloor M2 or M3.