Pandrol

Rail Equipment Catalogue

Our products stand the test of time. Which is why they’re chosen by half the world’s rail networks – equivalent to the distance from the earth to the moon. Our customers trust us to help them achieve their goals. And if anything falls short of our shared standards, they know we’ll put it right, right away.

Welding Equipment

Pandrol offers a range of equipment designed to support welders deliver high quality welds efficiently and effectively. From shearing and alignment, to sawing and tamping, the product range is designed to be used alongside all aluminothermic welding processes.

Grinding Equipment

In addition to being ergonomically designed for safe use by the operator, Pandrol’s range of grinding equipment is developed to maximise the life of the track across all rail heads and profiles.

Power Units

Offering a range of modular and mobile power units and work carts to meet all of your on-track power requirements.

The range includes diesel, electric, and hydraulic solutions to suit all track maintenance activities.

Clipping Equipment

Pandrol develops and manufactures a wide range of modern clipping equipment which drives efficient construction and maintenance of rail infrastructure.

Pandrol clipping machinery adds value to tasks from track renewals and installation to welding and sleeper change operations.

Hy-Rail Equipment

Pandrol has developed a range of Hy-Rail equipment to adapt the most common type of excavators for use on rail.

The Hy-Rail solutions, for use with excavators ranging up to 20 tons, offer significant advantages over heavy and immobile traditional machinery.

Carrier-mounted Attachments & Trailers

We design, manufacture and market high productivity machinery, equipment and working processes for efficient construction and maintenance of railways.

We developed new methods and design innovative equipment to safely speed up and increase productivity on the railways.

Rail Maintenance

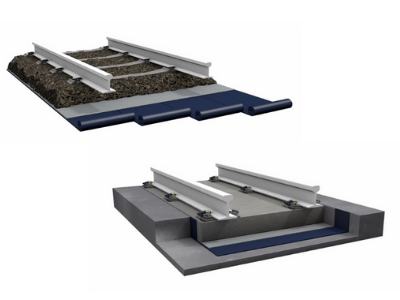

By minimising installation time we reduce or even eliminate the need for track possession. We create products suitable for all environments regardless of sleeper type, rail fastening or whether they are being used on ballasted or slab track. Operational efficiency, flexibility and reliability are critical factors in the design of every product.

Track-mounted Equipment

Our range of track-mounted equipment has been designed with efficiency in mind. They support reduced track downtime and possession requirements.

Track Control Solutions

Rail networks have an increasing need to understand the condition of their track, allowing them to implement efficient maintenance operations.

Pandrol’s inspection services and equipment are suitable to all types of network and provide valuable insights for the safety and longevity of the track.

Condition Monitoring

Pandrol has developed a range of sensing technology that enables quick and extremely cost effective remote condition and fault monitoring of key assets in the railway. Built around the innovative Multi-Sensor product, the Measure and Detect system can be used to monitor a range of rail infrastructure conditions including wheel flats, bogie hunting, stress free temperature, core rail temperature, rail and bridge strain, and ground disturbance.

Signalling & Detection

By minimising installation time we reduce or even eliminate the need for track possession. We create products suitable for all environments regardless of sleeper type, rail fastening or whether they are being used on ballasted or slab track.

Operational efficiency, flexibility and reliability are critical factors in the design of every product.