Evident

Non-destructive Testing for Weld Inspection – Tailored Solutions

This article first appeared in the Railway-News magazine Issue 5 2021.

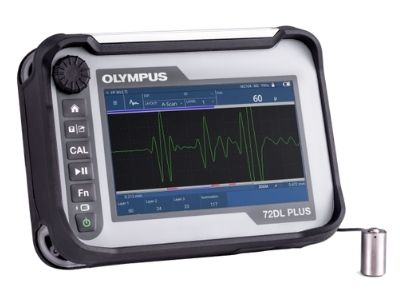

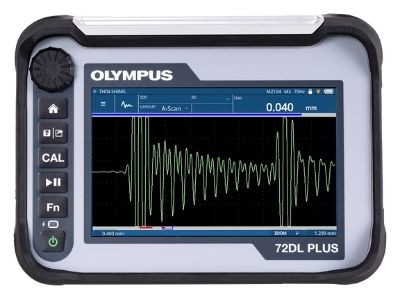

Olympus is a global leader and supplier of advanced non-destructive testing (NDT) equipment, specialising in innovative, turnkey solutions that offer the latest in weld inspection technology.

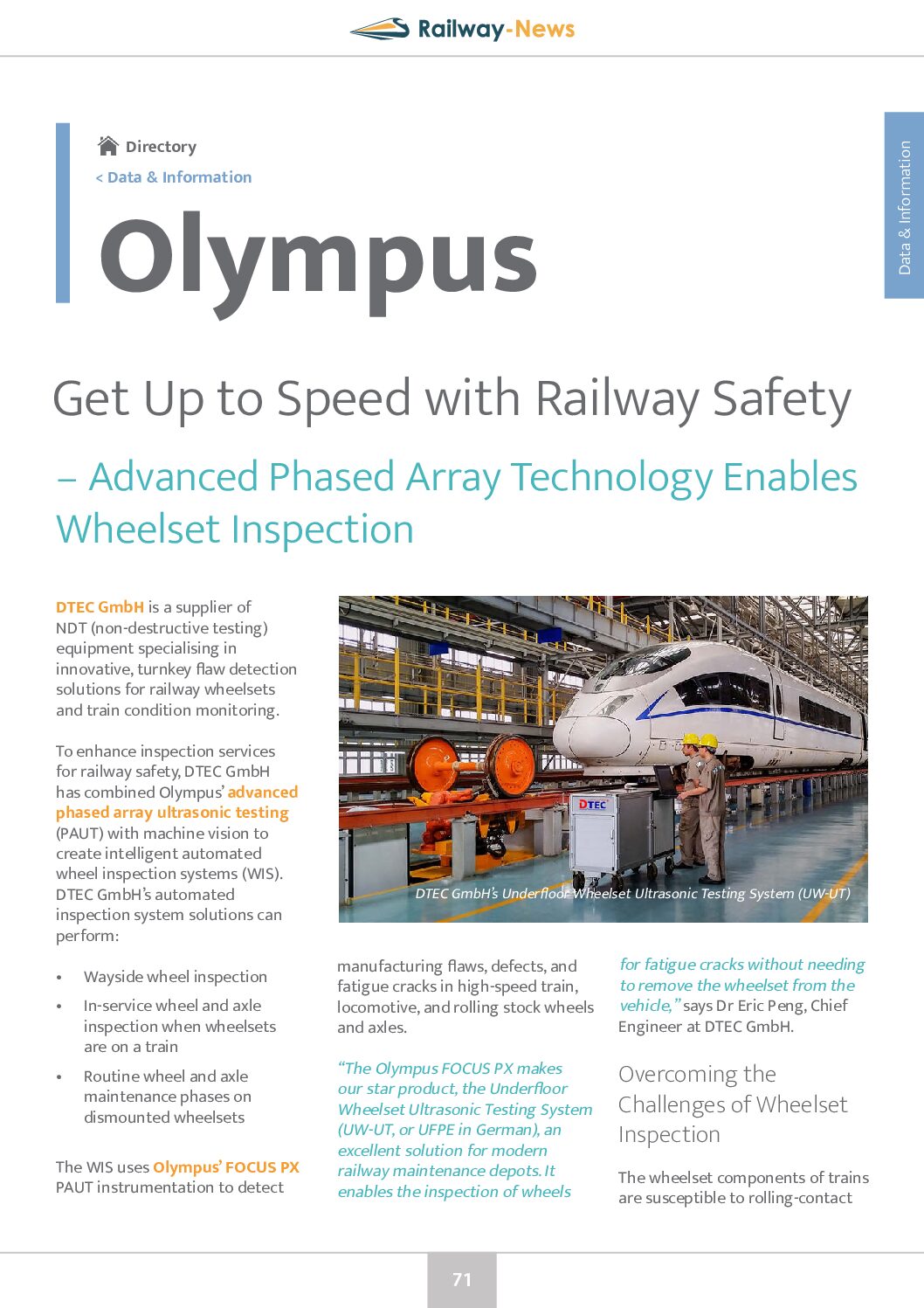

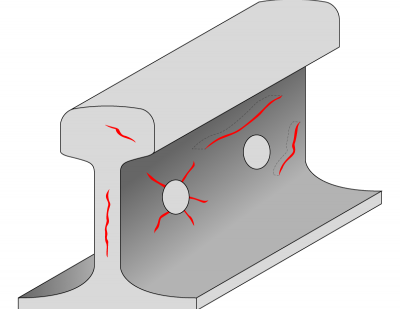

Olympus constantly strives to provide wider solutions for carrying out non-destructive testing within the rail industry. One such example to enhance the weld inspection process combines an automated non-destructive testing platform with a sturdy and compact cart, to create an innovative solution for large-diameter circumferential weld inspection.

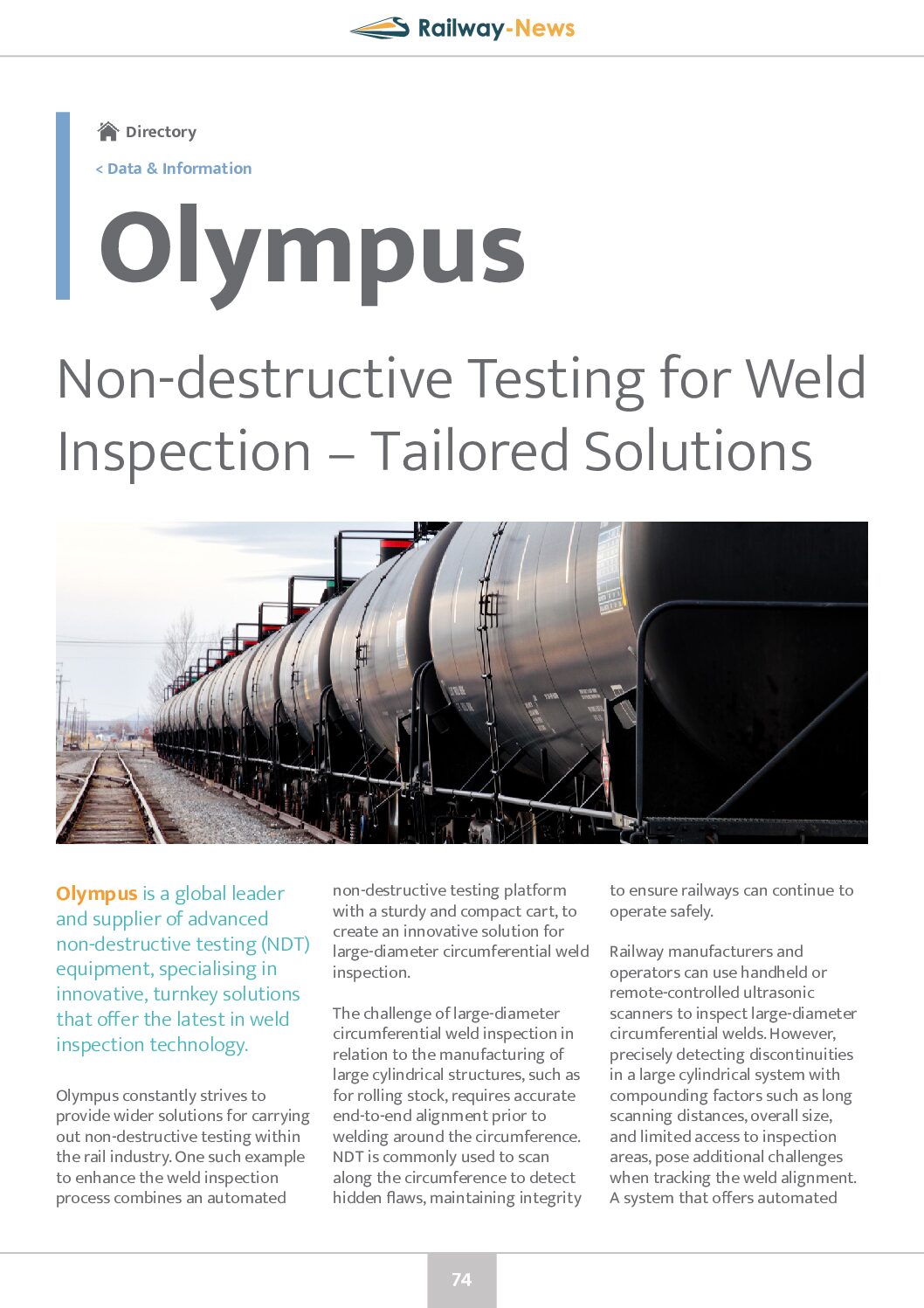

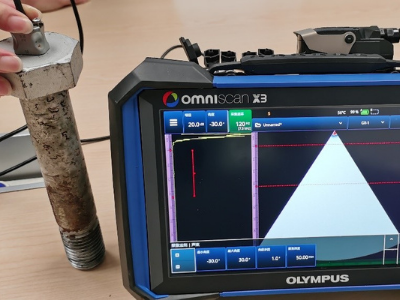

The challenge of large-diameter circumferential weld inspection in relation to the manufacturing of large cylindrical structures, such as for rolling stock, requires accurate end-to-end alignment prior to welding around the circumference. NDT is commonly used to scan along the circumference to detect hidden flaws, maintaining integrity to ensure railways can continue to operate safely.

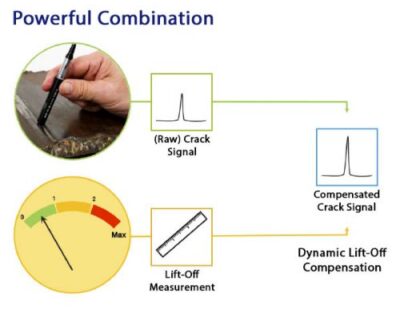

Railway manufacturers and operators can use handheld or remote-controlled ultrasonic scanners to inspect large-diameter circumferential welds. However, precisely detecting discontinuities in a large cylindrical system with compounding factors such as long scanning distances, overall size, and limited access to inspection areas, pose additional challenges when tracking the weld alignment. A system that offers automate scanning would enable operators to more accurately and reliably detect weld flaws.

An Automated Solution for Circumferential Inspection

Olympus’ NDT solutions offer just that, in the form of an innovative weld-tracking inspection head on a sturdy mobile cart. Several types of ultrasonic probes allow the inspection head to be positioned in orientations that enable the reliable and accurate detection of weld flaws. At the same time, the cart’s inspection head is positioned against a weld in a cylindrical product that is horizontally orientated, enabling the laser camera on the head to track weld alignment while the product turns. The inspection head sends instant and continuous feedback to a horizontal actuator for a simplified inspection workflow.