ZF Group

Keeping an Eye on Everything with ZF’s connect@rail Solution

This article first appeared in the Railway-News magazine, Issue 1 2023.

Reliability in rail transportation – be it cargo or people – is more important than ever.

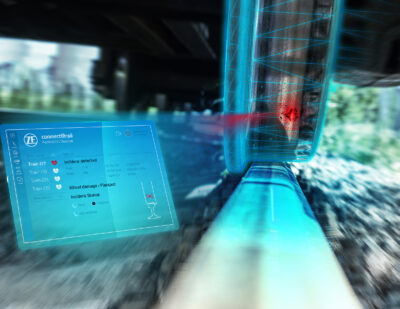

Operators and manufacturers must keep downtimes to a minimum, safety and comfort at a maximum, and avoid failures at all cost. Fortunately, ZF is able to support companies with its smart and digital connect@rail system for condition monitoring and maintenance management.

Smart. Thorough. Digital.

Connectivity and digitalisation have become an integral part of our everyday lives. The enormous quantities of information available everywhere and in real time make new functions and business models possible that were unthinkable a few decades ago. With connect@rail, ZF leverages its extensive expertise as a leading global company for driveline, chassis and safety technology. The system is a comprehensive and modular approach to fleet maintenance management and condition monitoring, with the following components:

- Heavy Duty TAGs, battery-operated Bluetooth wireless sensors that are placed on the vehicle bogies. There, they measure acceleration, vibrations and other parameters.

- Gateways, the VCU Pro Onboard Units, with CAN interfaces, several analogue input and digital output ports that support Wi-Fi and all common GNSS. The gateway is able to store and pre-process data gathered by the sensors.

- The ZF IoT Cloud, accessed via said secure onboard gateway, uses the collected and enriched data to detect wear, damage and abnormality early and precisely.

- A dashboard for desktops and mobile devices that gives end-users a comprehensive overview of all parameters, reports, maintenance schedules and more.

- Digital typeplates with an integrated RFID chip that log actual installation position and hours of service of individual components. They both facilitate and keep records of scheduled maintenance.

With these hardware and software components, the connect@rail infrastructure and driveline monitoring system is able to monitor flat spots, wheel-tread wear, tracks and even driveline components. As it can be integrated and retrofitted into existing vehicle platforms and is not dependent on ZF-proprietary hardware, it offers manufacturers and fleet operators an efficient way to reduce downtimes. Thus, it helps keep public and cargo transport running efficiently.