ASC Sensors

Sensors from ASC Help Deutsche Bahn Identify Track Damage Early On

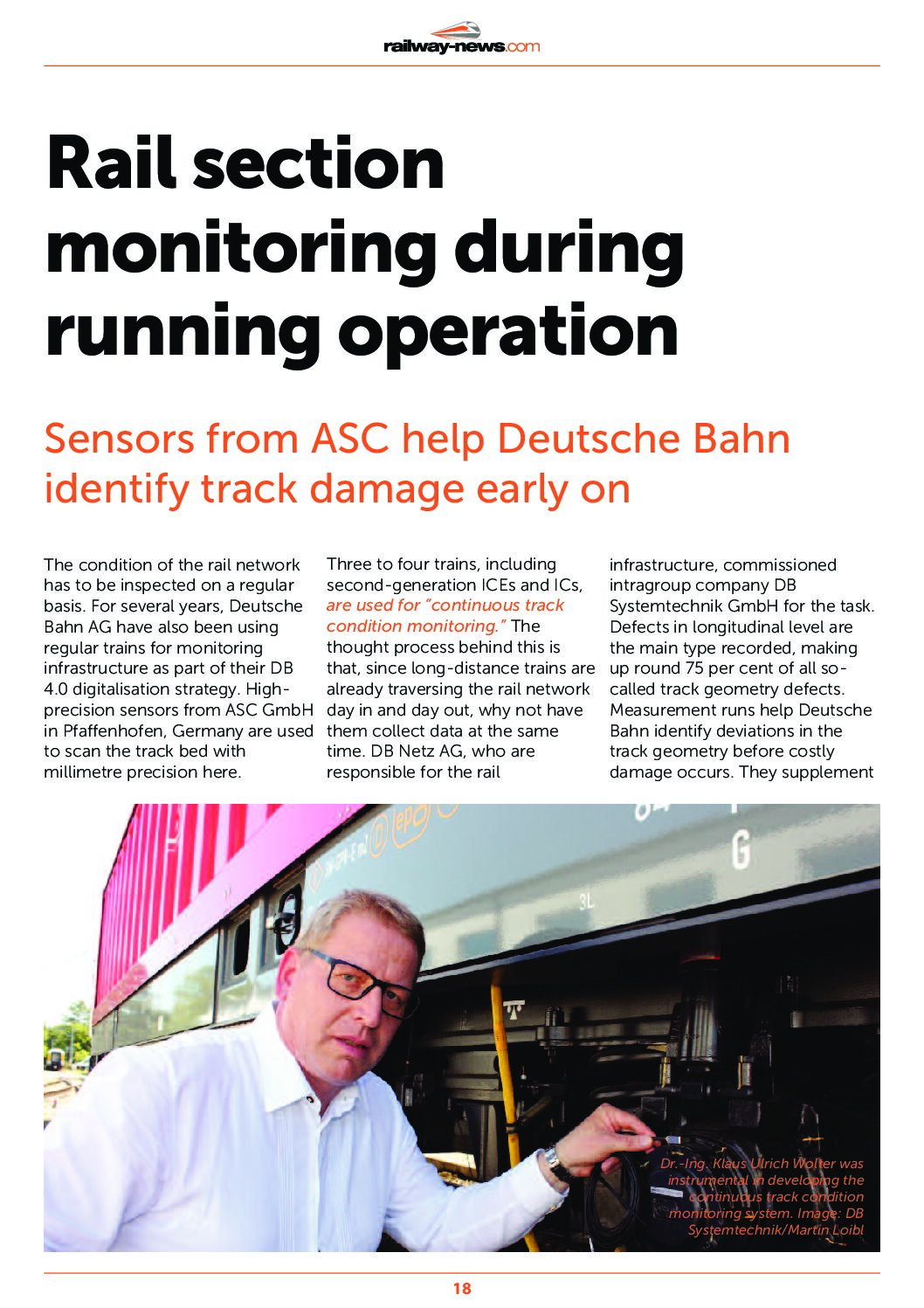

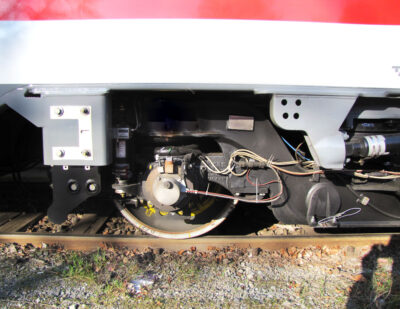

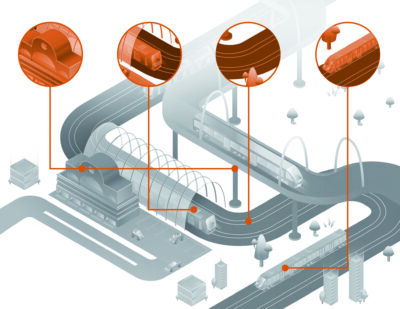

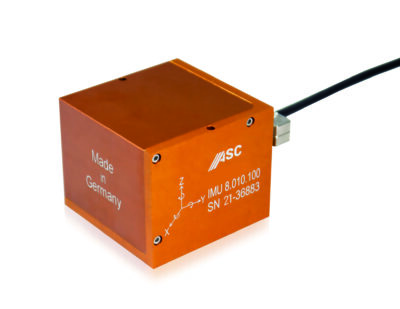

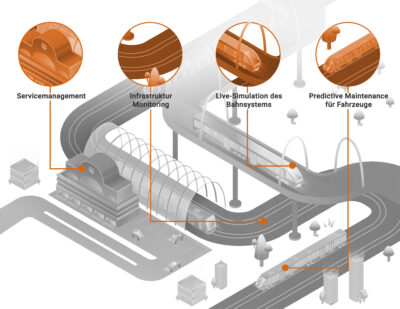

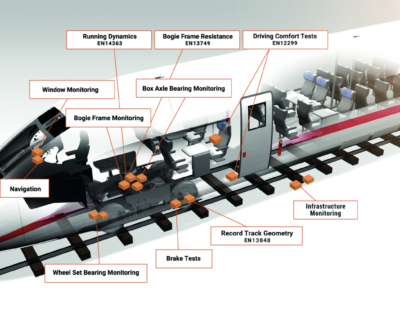

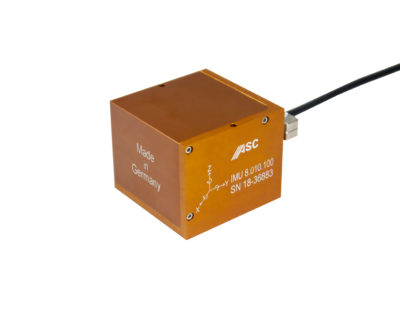

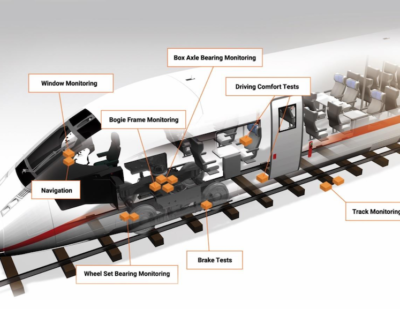

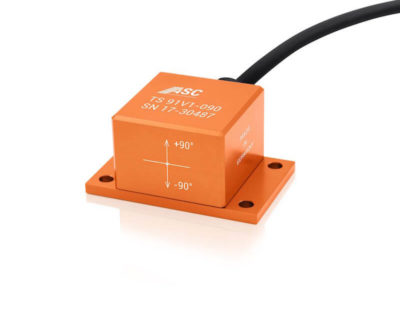

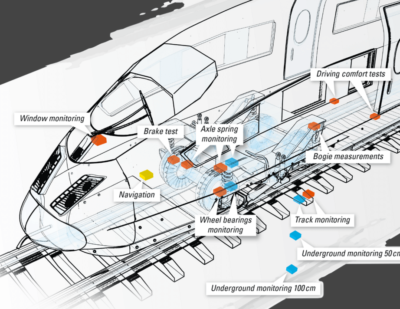

The condition of the rail network has to be inspected on a regular basis. For several years, Deutsche Bahn AG have also been using regular trains for monitoring infrastructure as part of their DB 4.0 digitalisation strategy. High-precision sensors from ASC GmbH in Pfaffenhofen, Germany are used for rail section monitoring with millimetre precision.

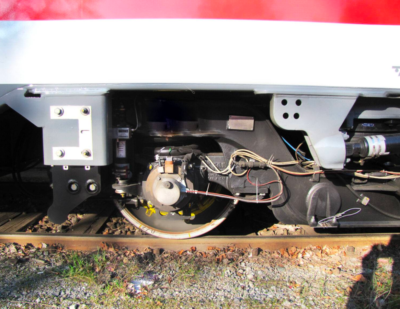

Three to four trains, including second-generation ICEs and ICs, are used for “continuous track condition monitoring.” The thought process behind this is that, since long-distance trains are already traversing the rail network day in and day out, why not have them collect data at the same time. DB Netz AG, who are responsible for the rail infrastructure, commissioned intragroup company DB Systemtechnik GmbH for the task. Defects in longitudinal level are the main type recorded, making up round 75 per cent of all so-called track geometry defects. Measurement runs help Deutsche Bahn identify deviations in the track geometry before costly damage occurs. They supplement regular inspection with track measurement trains at longer intervals, with high-speed rail sections usually being examined every three to four months and regional train sections once a year.

Continuous Track Condition Monitoring is A Great Success

Since the introduction of continuous track condition monitoring, the mobile measurement technology has already been used over more than 6,000,000 kilometres. Based on the data obtained, measures were initiated which considerably improved the quality of the superstructure comprised of the rails, sleepers and ballast. This made it possible to reduce the number of speed-restricted sections and track blockages by an average 95 per cent. A further indicator of the success of monitoring is the great interest in measurement data seen by persons responsible for rail systems. As requested by them, more and more sections of rail will be included for monitoring, bit by bit.

At present, continuous track condition monitoring is still limited to long-distance sections, but Dr. Wolter is already considering expansion: “The technology is definitely also of interest for the extensive rail network of regional trains.”

Click download below to read the complete article.