ORBIS

This article first appeared in the Railway-News Magazine Issue 1, 2022.

The Problem

Managing automated test equipment (ATE) obsolescence is a common and persistent challenge in the railway industry. With locomotive and railcar lifespans exceeding 25 years, the equipment used to test and maintain critical components must keep pace. But how do you accomplish this when the service life of most test and measurement equipment is typically less than 10 years? A recent review of one transit authority ATE revealed that 80 percent of the system components were at or nearing end of life after nine years in service.

Unplanned downtime of testing assets can significantly impact a transit authority or supplier’s ability to carry out proper testing and maintenance of critical rail components. When a test system fails, the length of downtime can vary from hours to months depending on several factors including the availability of replacement hardware.

Where fit, form and function replacements are no longer available, getting a system up and running may require significant design changes. Additionally, systems that use proprietary hardware or communication protocols may require the support of the original equipment manufacturer (OEM) or reverse engineering if a company is no longer in business.

In this article, we will explore proactive strategies to extend the lifespan of ATE and ensure uninterrupted test coverage throughout the lifespan of the programme.

ATE in the Mass Transit Industry

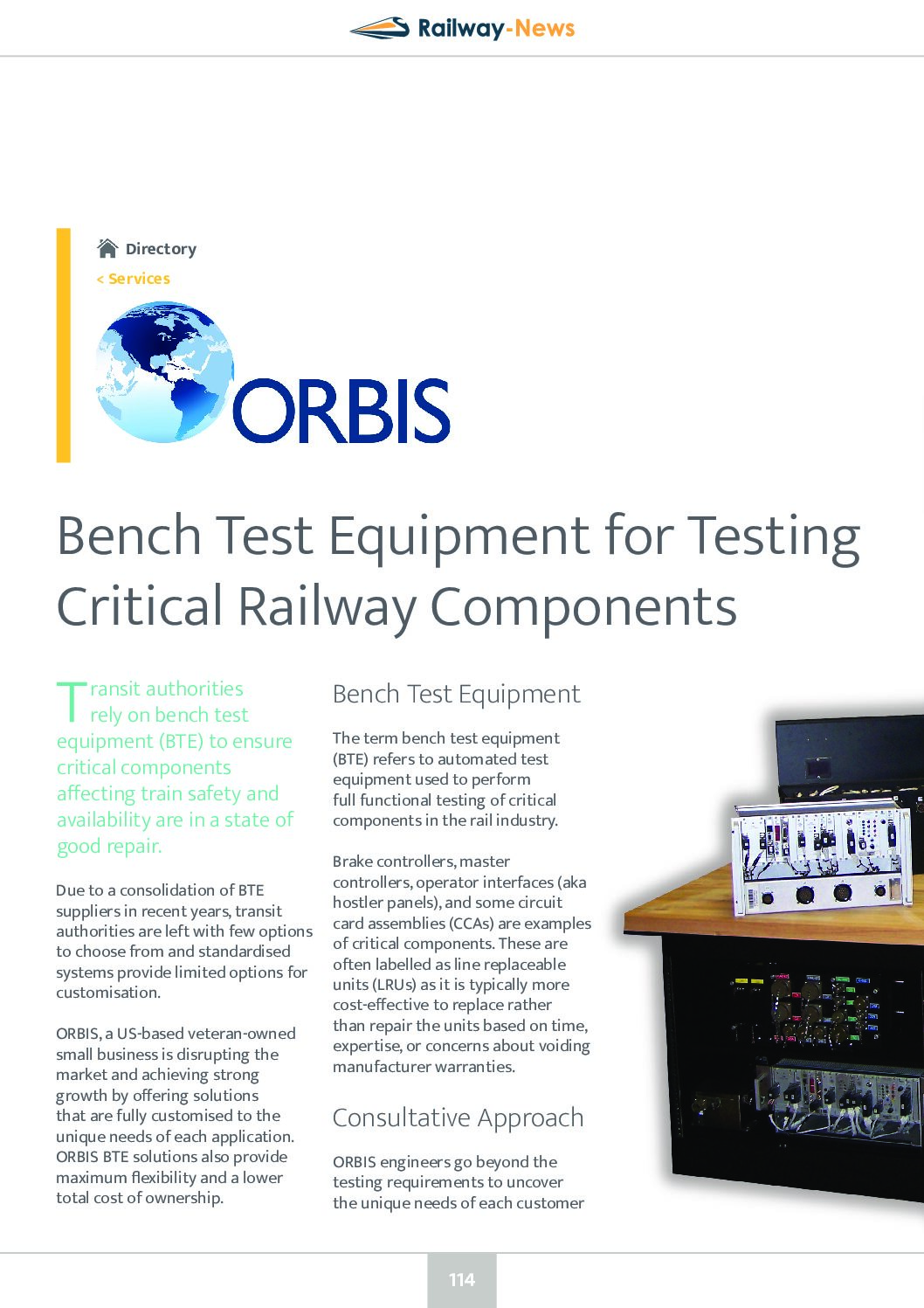

ATE in the transit industry is often referred to as BTE, which is short for bench test equipment. These systems are used by maintenance personnel to perform full functional testing and troubleshoot problems. For complex electronic devices such as brake controllers, BTE systems often allow technicians to diagnose problems to the lowest line replaceable unit (LLRU). A typical BTE consists of test and measurement (T&M) instruments such as digital multimeters, oscilloscopes and function generators as well as hardware needed to communicate with the device under test (DUT). Of course, software is the glue that holds everything together.