Automatic Component Measuring Station

Amest s.r.o. specialises in the development, construction, installation and service of control stations, observation gauges and measuring machines for production control of component dimensions and shapes. It also specialises in non-destructive flaw detection identification of mechanical properties and defects in materials, as well as weight control in the mass production of components, including their labelling and sorting according to chosen parameters.

AMEST measuring and control technology features:

- Controls required shape dimensions within a narrow tolerance, and with appropriate exactness

- Reveals a defective component early, and withdraws it from further production processes

- Minimizes the waste rate, thereby decreasing production costs

- Enables the user to meet deciding conditions for getting their product quality certification

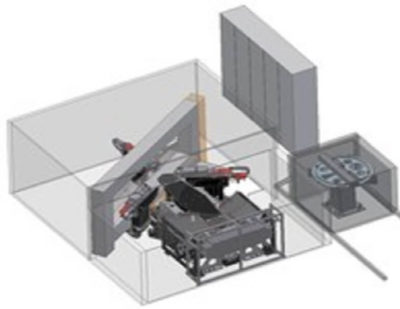

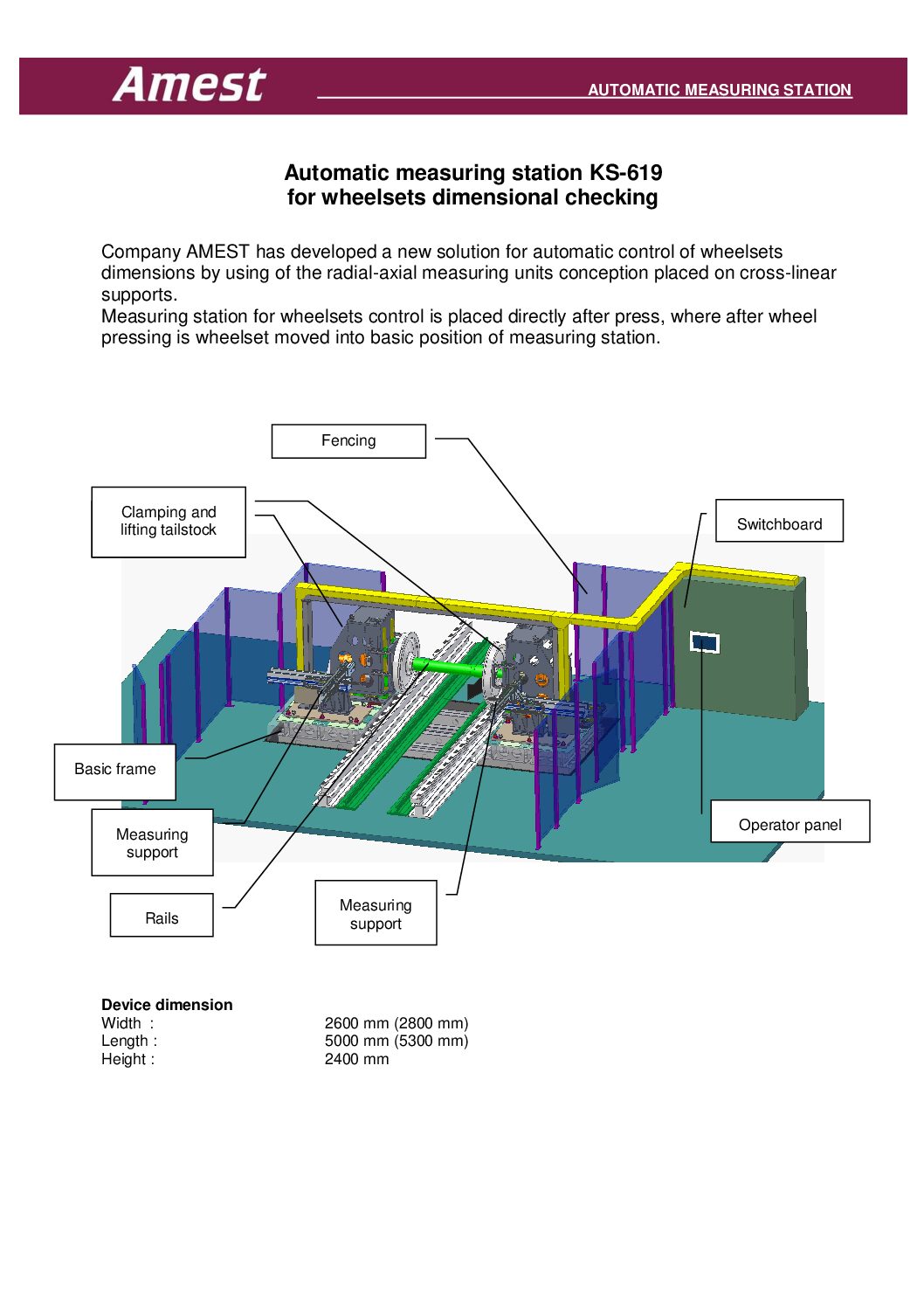

Train Component Measuring Stations

AMEST monitoring and measuring stations secure complex interstage and final inspections of components, assemblies, and final products. They check the dimensions, shapes, required weight, quality of finish and monitor the quality requirements of the material used. They can be equipped with automatic feed of controlled components, special dimension sensors, search units for checking by turbulent flow, scales, markers and automatic sorting of inspected components according to chosen parameters. Simultaneously they signal defects and give orders to operation interventions within a given production operation (corrections, machine adjustment, tool exchange, etc).

Using AMEST measuring stations minimizes the human factor influence on the production process control, which tends to be the most common cause of an inspection and measuring defect.

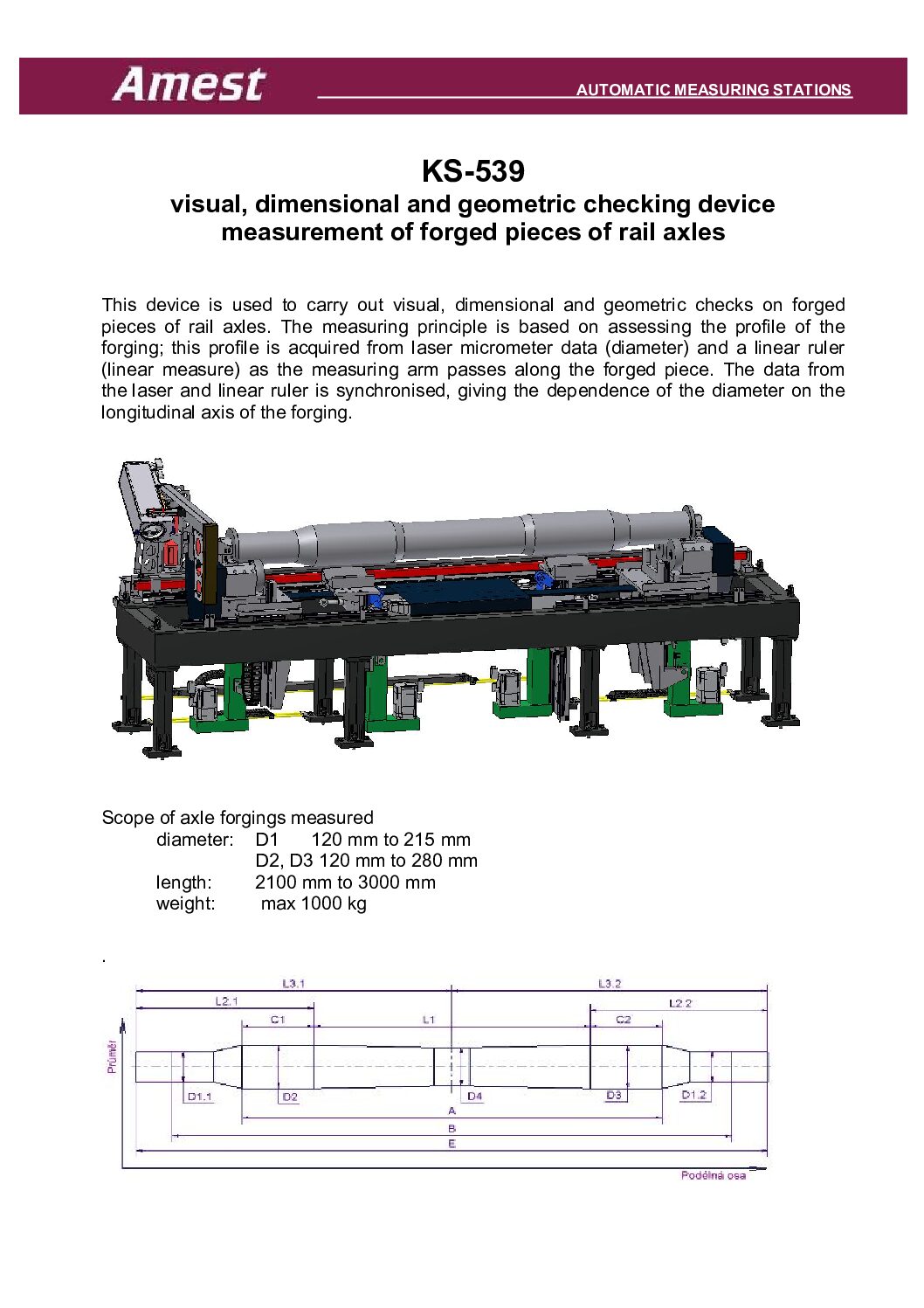

Dimensions Control of Wheels, Axles and Wheelsets

Amest has grown from a regional business to a global presence. With equipment situated on important customers plants as Lucchini Italy, Interpipe Ukraine, Uralvagonzavod Russia. ZHIBO Lucchini and Taiyuan Heavy Duty China company Amest proving that their own development and technical knowledge has a big rating in railway industry.

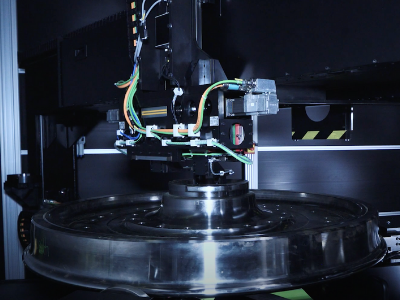

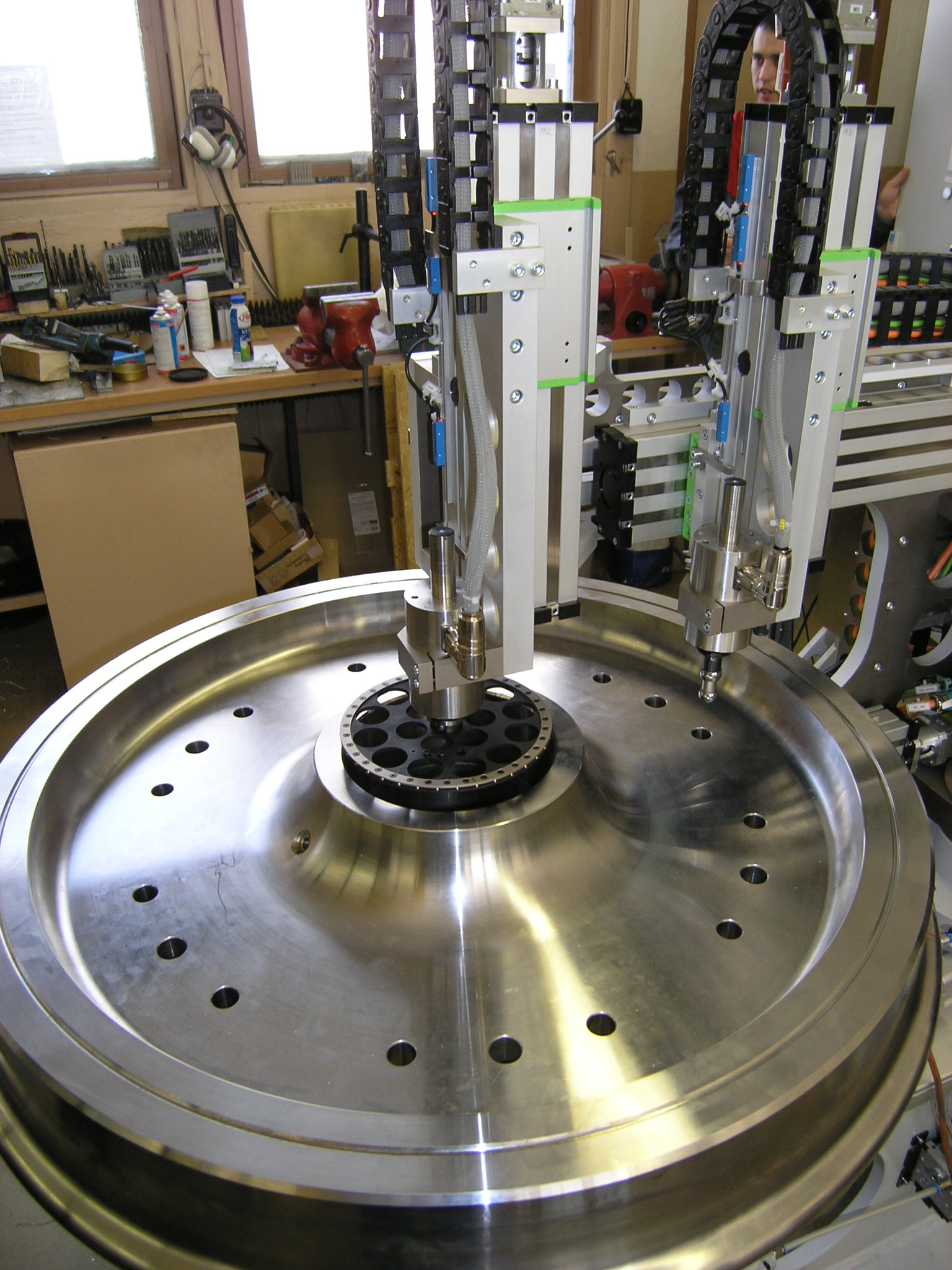

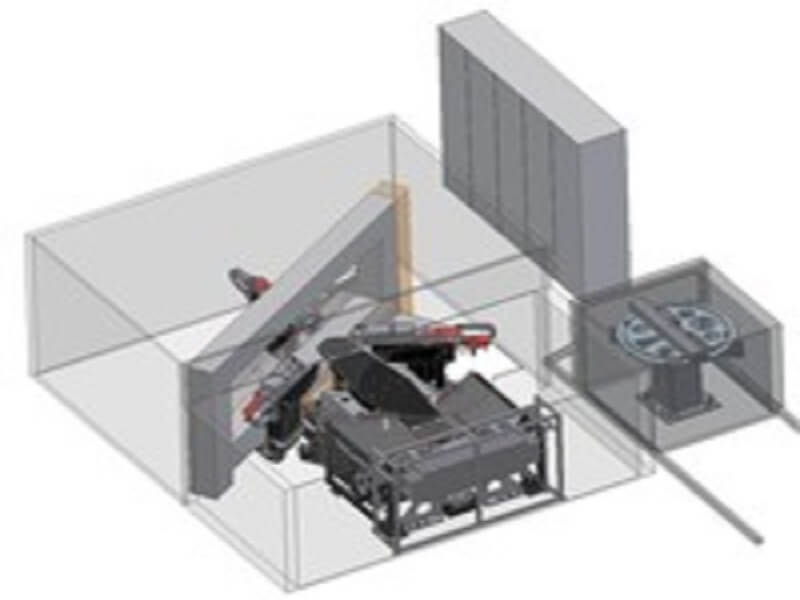

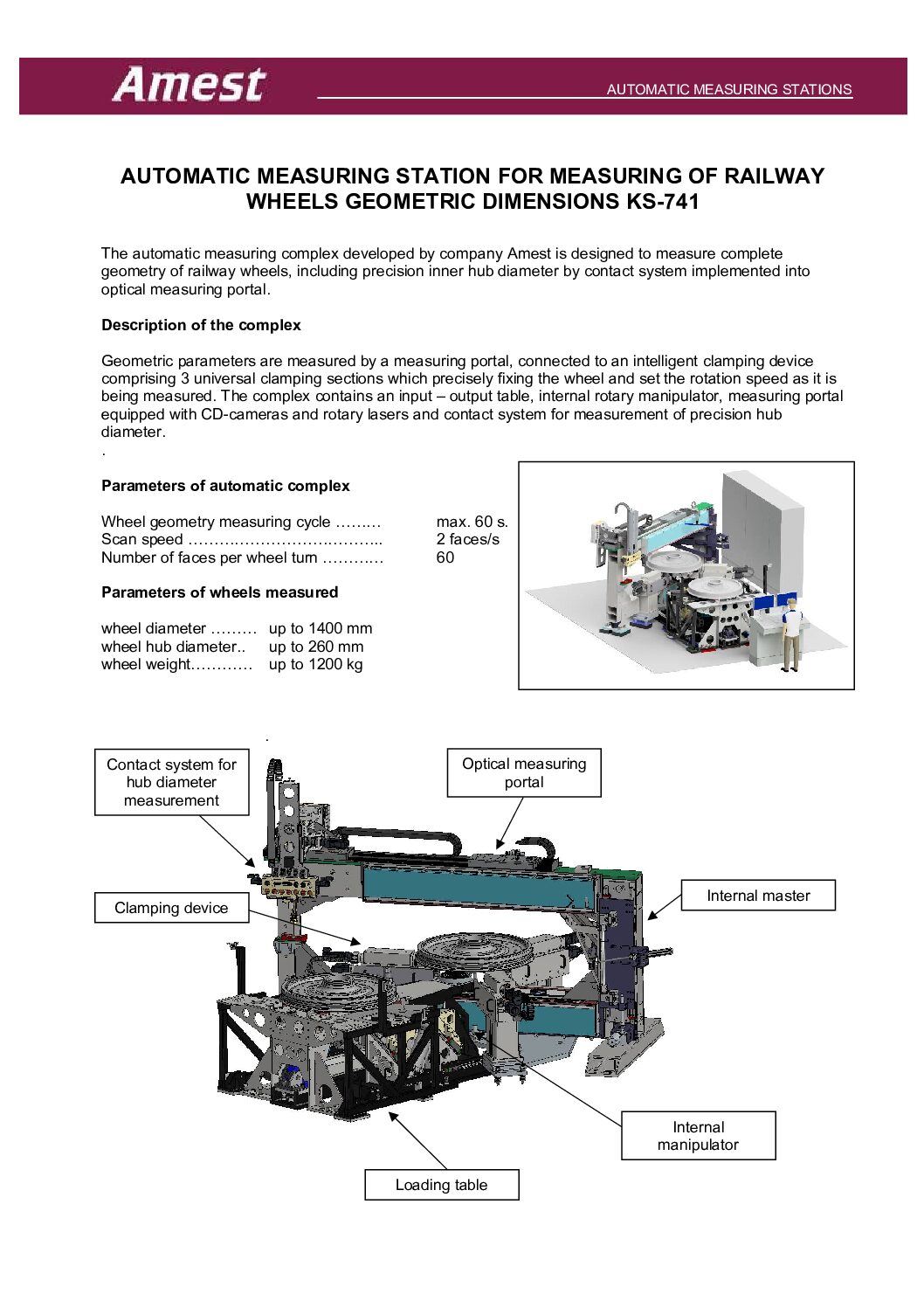

Wheel Geometry Dimensions Measurement

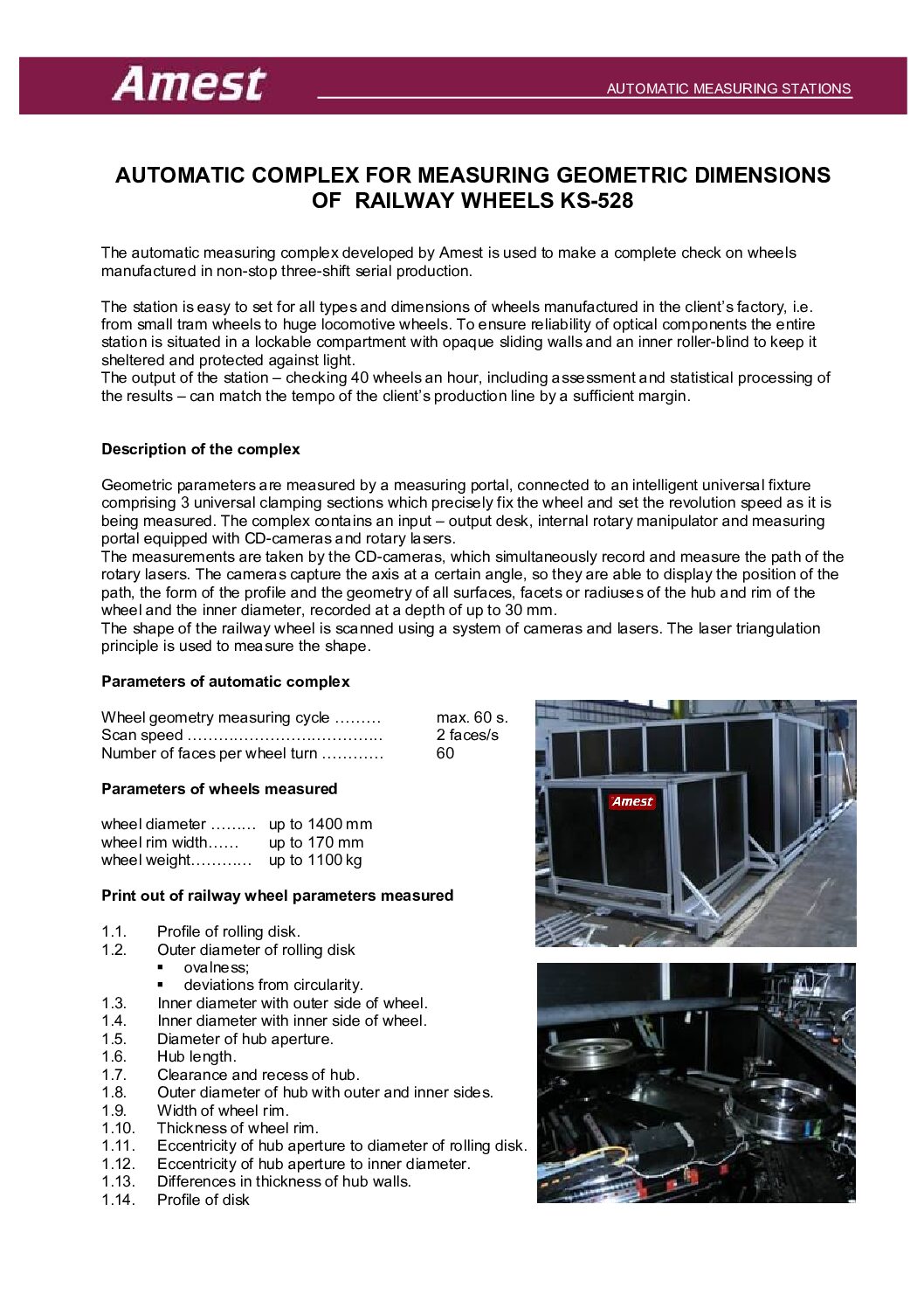

The automatic measuring complex KS-528 developed by Amest is used to make a complete dimension check on wheels manufactured in non-stop three-shift serial production.

The station is easy to set for all types and dimensions of wheels manufactured in the client’s factory, i.e. from small tram wheels to huge locomotive wheels. The output of the station – checking 60 wheels an hour, including assessment and statistical processing of the results – can match the tempo of the client’s production line by a sufficient margin.

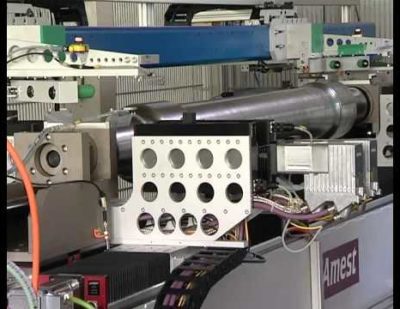

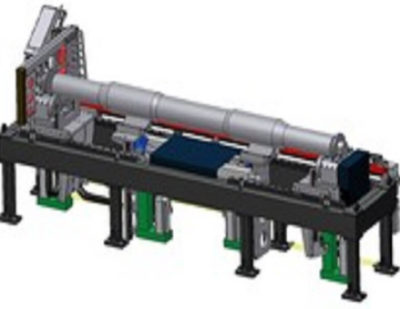

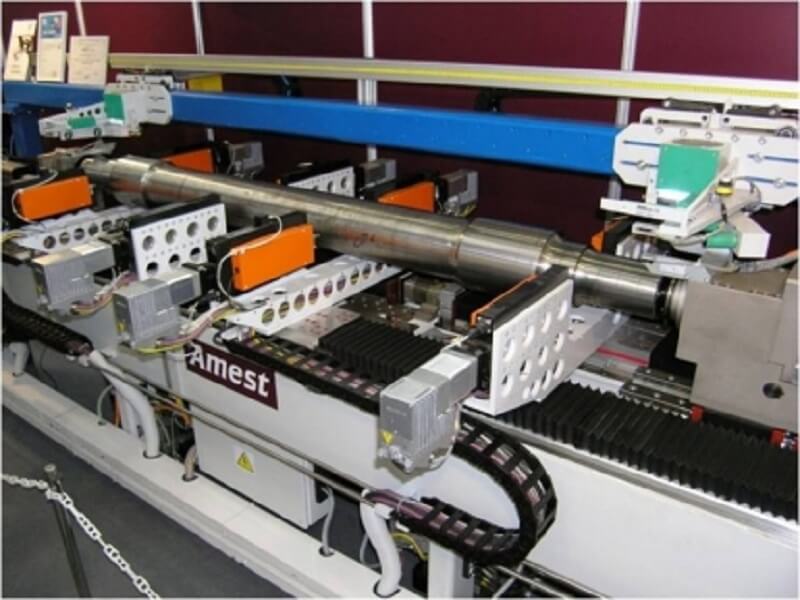

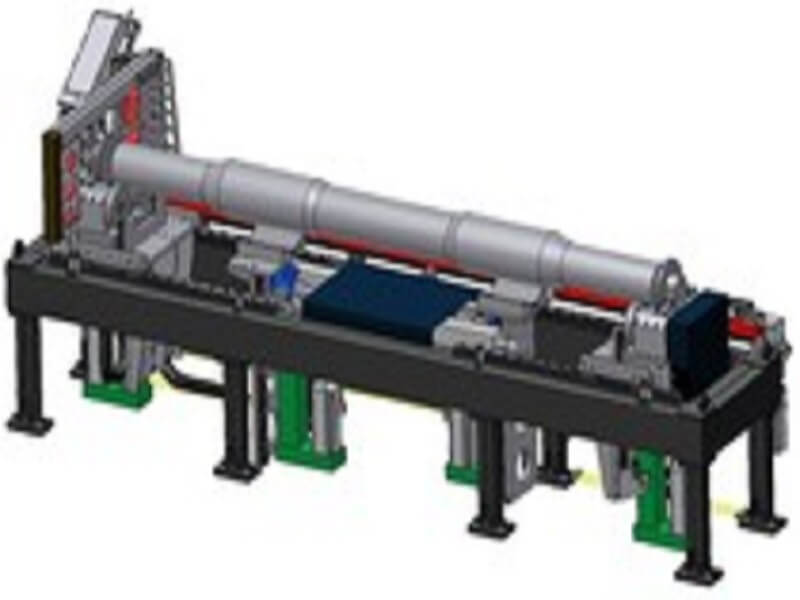

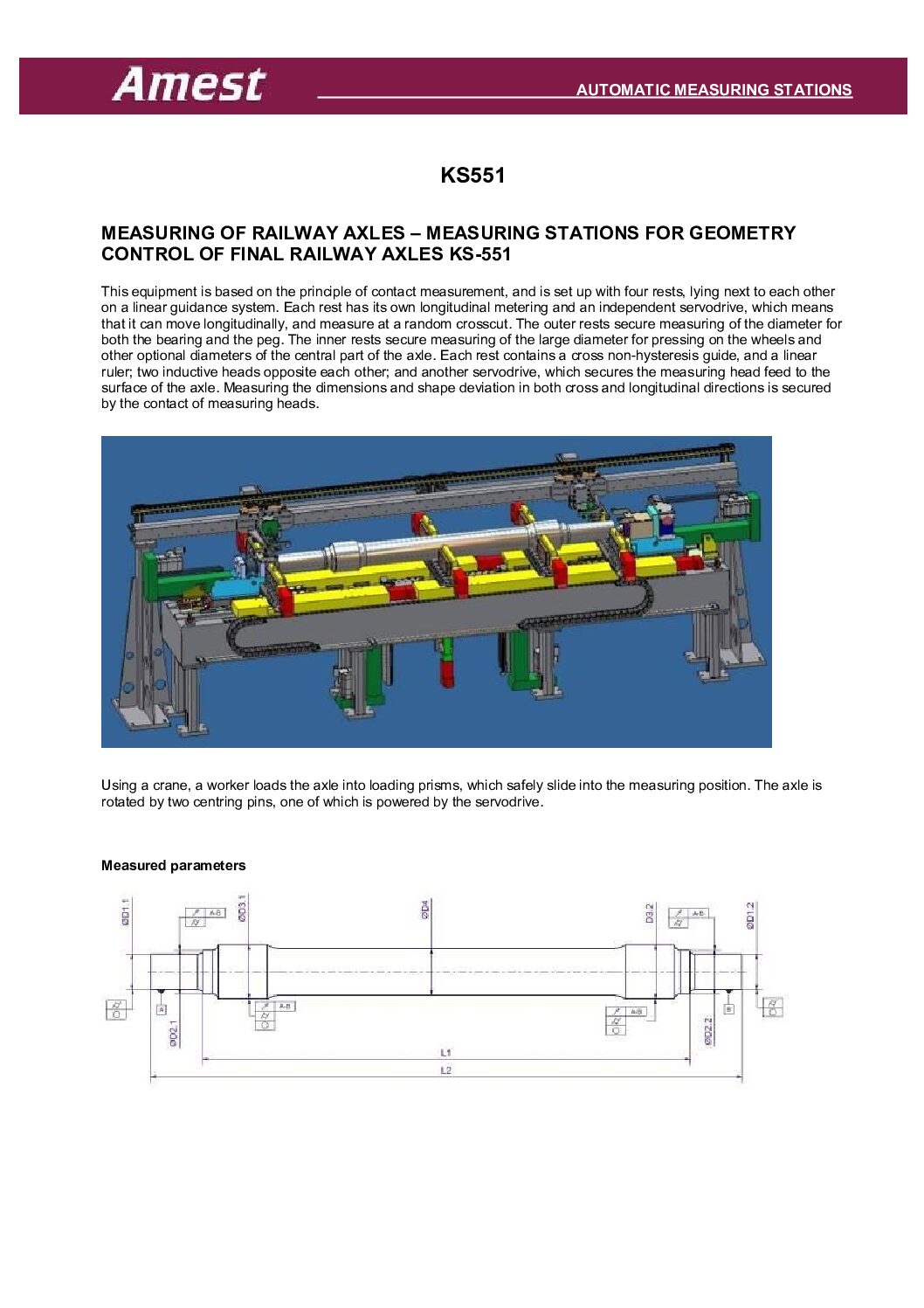

Axle Geometry Dimension Measurement

The automatic measuring device KS-551 is used for complete dimension check of all kinds of axles. Big flexibility and short measuring cycle time giving to customer in short time all needed results for following machining process and audit management. Please watch the below videos to see our KS-528 and KS-551 in action:

If you have any questions please do not hesitate to contact us and we will try and help you in any way we can.

amest.cz/en/